Sub-packaging and conveying device of columnar parts

A conveying device and sub-packaging technology, which is applied in packaging and other directions, can solve the problems of manual sub-packaging, complex structure of sub-packaging equipment, high price, etc., and achieve the effect of avoiding labor, low cost and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

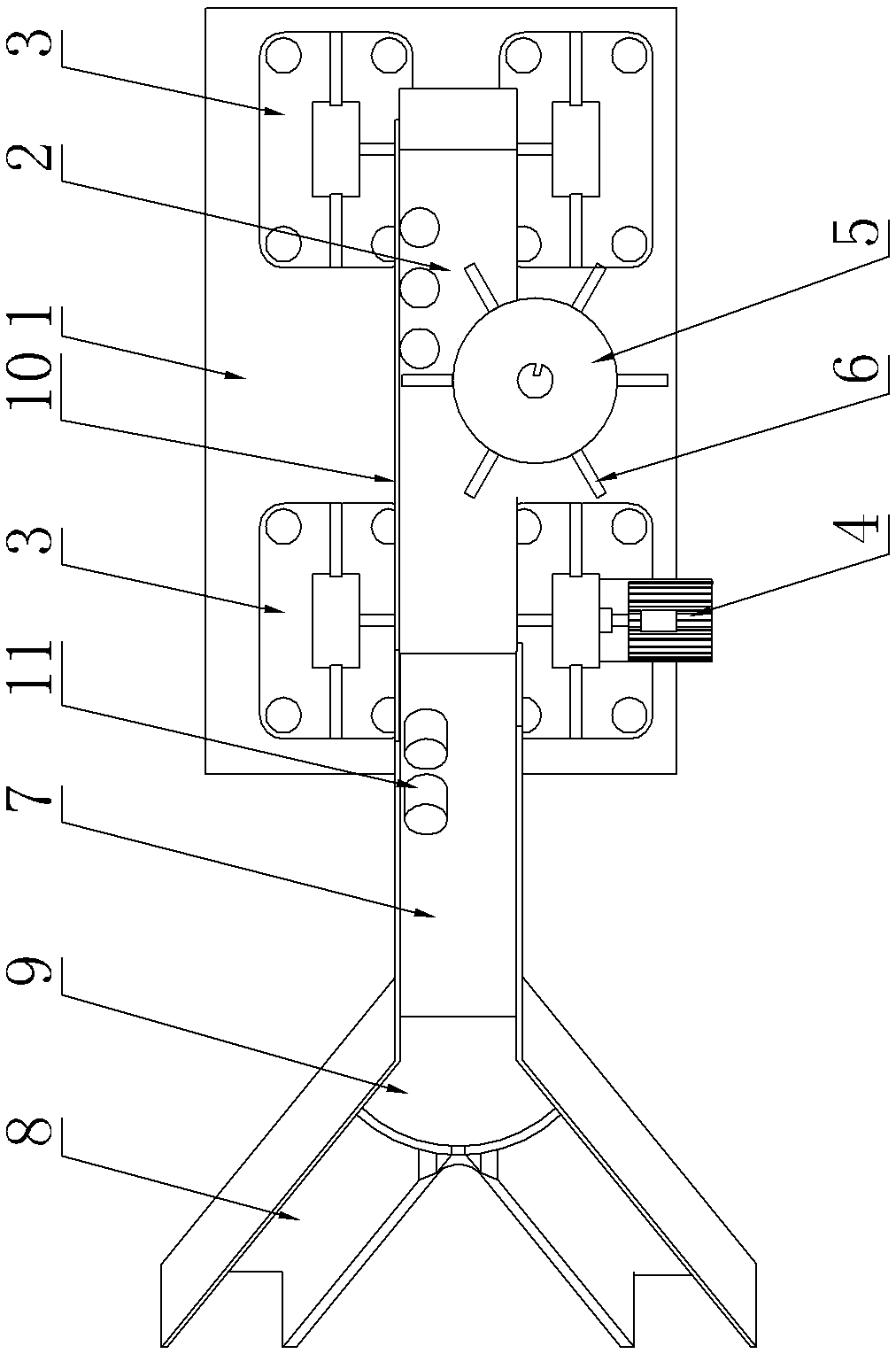

[0012] Such as figure 1 Shown, a kind of dispensing conveying device of cylindrical parts, it comprises:

[0013] The conveyor belt mechanism, the conveyor belt mechanism includes a conveyor belt 2, the conveyor belt 2 is sleeved on a pair of rollers, and the pair of rollers are respectively supported on the support seat 3, the roller is driven by the first motor 4, and the support seat 3 is fixed on the seat body 1 Above, the first motor 4 is fixed on the support plate on the side of the support seat 3, and the side of the conveyor belt 2 is provided with a baffle;

[0014] Quantitative transmission mechanism, the quantitative transmission mechanism includes an indexing wheel 5, the indexing wheel 5 is set above the conveyor belt 2 and driven by a second motor, the second motor is fixed on the base 1 through a support block, and the side of the indexing wheel 5 is fixed There are six indexing plates 6 evenly arranged around the axial direction, and adjacent indexing plates 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com