Array type nozzle plane cleaning device and self-cleaning maintenance-free electrostatic purification system

A cleaning device and array-type technology, applied in electrostatic separation, electrode cleaning, etc., can solve the problems of low work efficiency, dust accumulation, long maintenance time, etc., and achieve the effect of preventing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1 Arrayed Nozzle Plane Cleaning Device—Cleaning Nozzles

[0089] In a specific embodiment of the present application, the arrayed nozzle plane cleaning device uses double-sided liquid outlets to clean the nozzles.

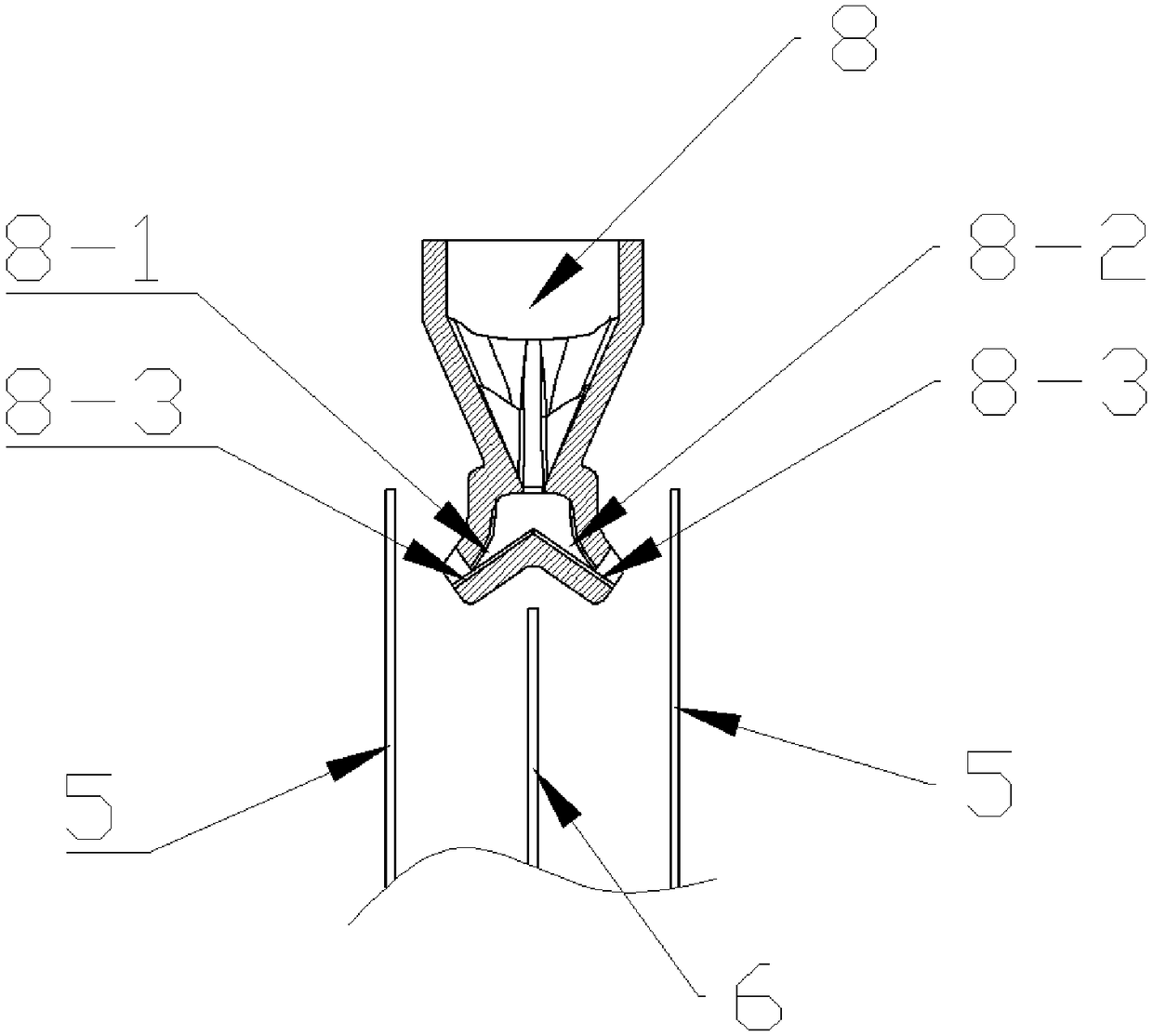

[0090] The structural representation of the cleaning nozzle 8 in the array type nozzle plane cleaning device is shown in figure 1 , the cleaning nozzle 8 includes a liquid outlet 8-1, a liquid outlet 8-2 and a flow guide part 8-3. The cleaning process is that after the cleaning liquid leaves the nozzle 8, it jets onto the dust collecting plate 5, and utilizes the nozzle 8 and the dust collecting The angular relationship between the plates 5 enables the cleaning liquid sprayed from the nozzle 8 to flush the dust collecting plate 5 tangentially, and then use the impact force of the cleaning liquid to effectively clean the dust on the dust collecting plate 5; combined with intelligent control System, and custom periodic cleaning, can realize artificial...

Embodiment 2

[0094] Example 2 Arrayed Nozzle Plane Cleaning Device—Cleaning Nozzles

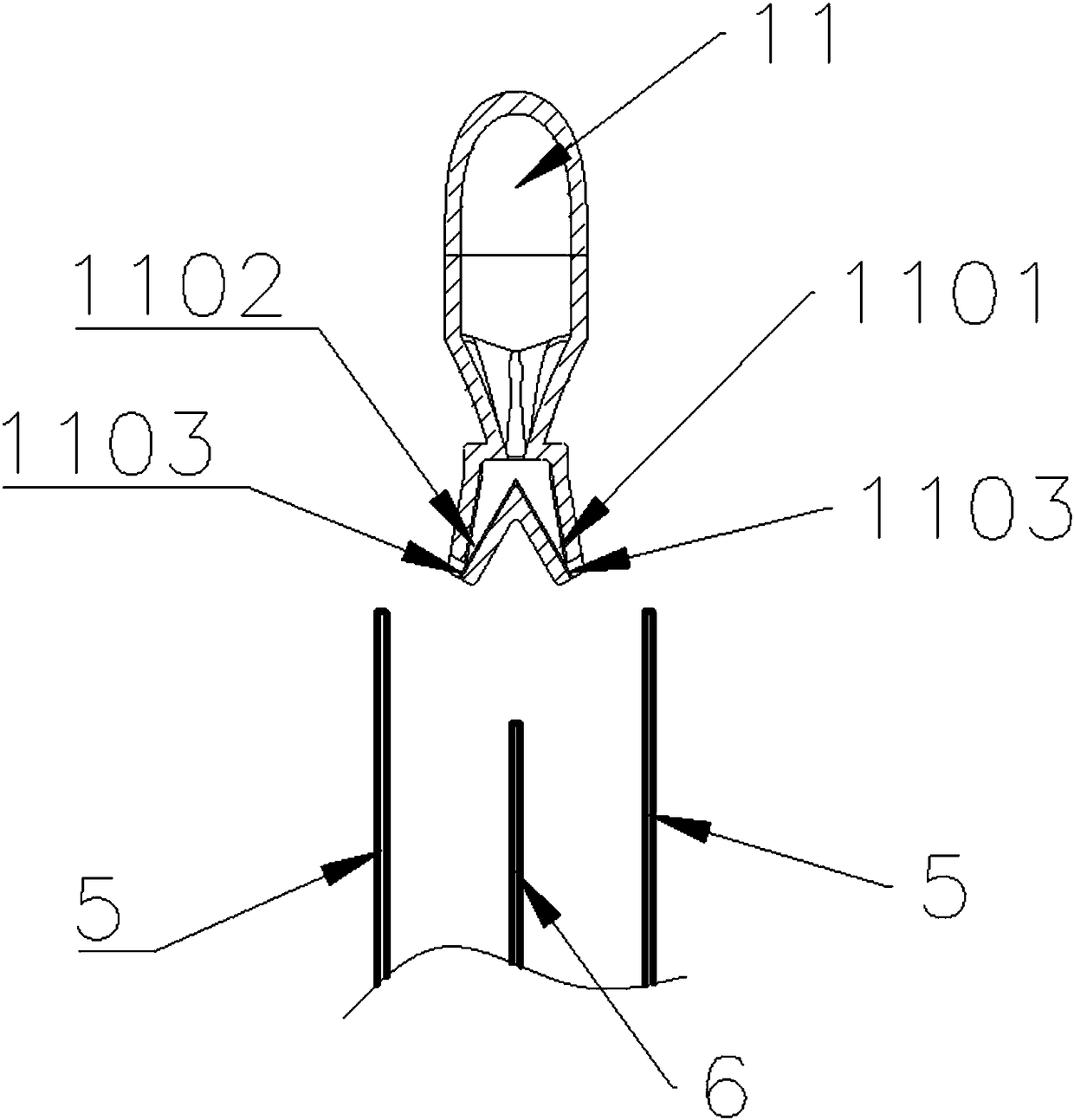

[0095] In a specific embodiment of the present application, the structure of the nozzles 11 in the array type nozzle plane cleaning device is shown in figure 2 , Unlike Embodiment 1, the lowest point of the nozzle 11 is higher than the highest point of the dust collecting plate 5 and the ionization plate 6 . The nozzle 11 includes a liquid outlet 1101 , a liquid outlet 1102 and a flow guiding part 1103 all located outside the gap between the dust collecting plate 5 and the ionizing plate 6 . Wherein, since the position of the liquid outlet 1101, the liquid outlet 1102, and the deflector 1103 is slightly farther from the dust collecting plate 5 than that of Embodiment 1, and the position is higher, the angle between the deflecting portion 1103 and the dust collecting plate 5 The lambda design is smaller than in Example 1. As several typical implementations, the distance d between the dust collecting pla...

Embodiment 3

[0098] Embodiment 3 One-side liquid outlet nozzle

[0099] Similar to the nozzle structure of embodiment 1, the difference is that the nozzle of this embodiment is a single-sided liquid outlet, please refer to Figure 14 , is a side view of the single-side liquid outlet nozzle of this embodiment. For the front view of the single-side liquid outlet nozzle in this embodiment, please refer to Figure 15 (b), the side view sectional view of its A-A direction is Figure 15 (a).

[0100] In a specific embodiment, in the array type nozzle plane cleaning device, two single-side liquid outlet nozzles of this embodiment are arranged between every two adjacent dust collecting plates 5, and the liquid outlets of the two nozzles respectively face Dust collecting plate 5 on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com