Printing presses with auxiliary paper loading

A printing machine and paper loading technology, which is applied in the direction of transportation and packaging, thin material handling, and object separation, etc., can solve the problems of not meeting high efficiency requirements, wasting manpower and time, and increasing labor costs, etc., and achieves a high degree of automation and improved Improve work efficiency and improve printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

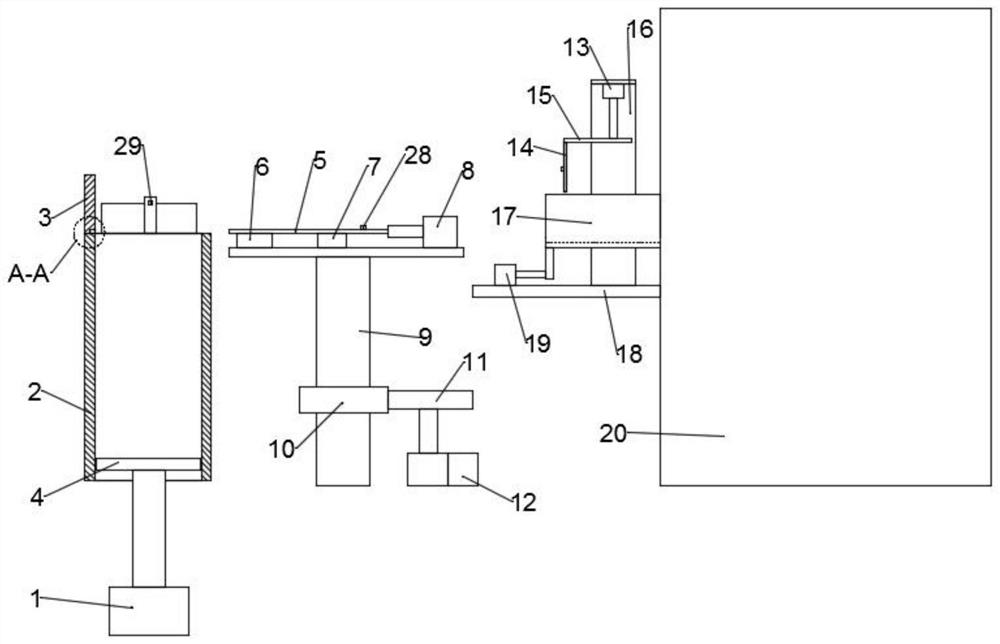

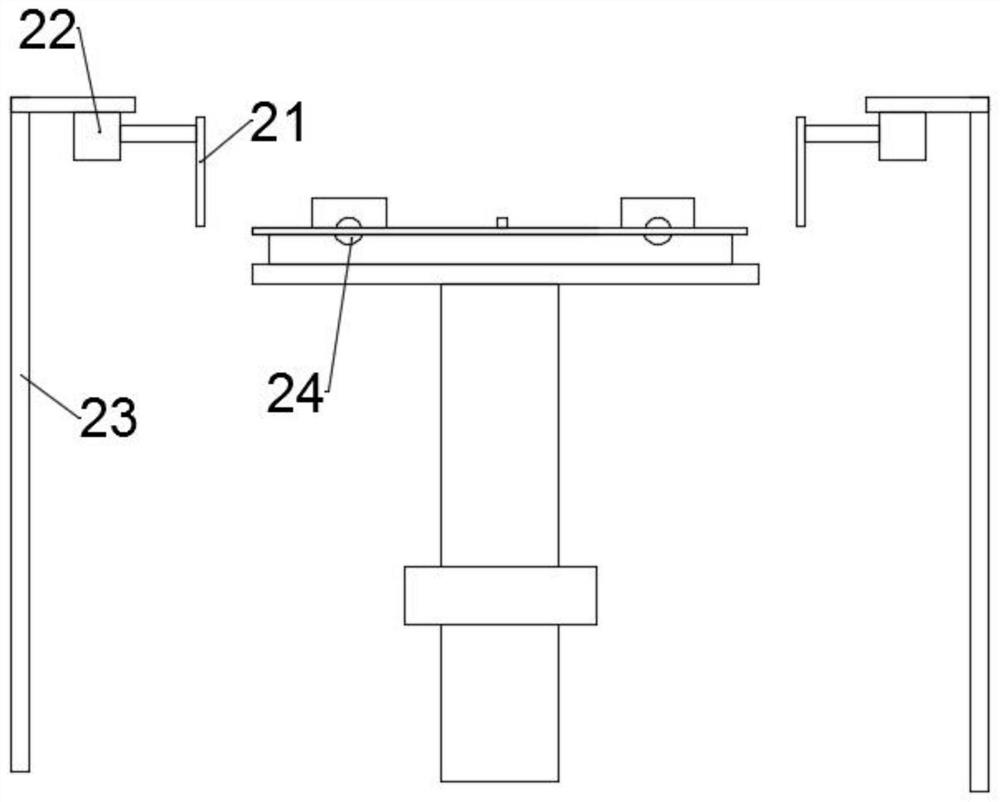

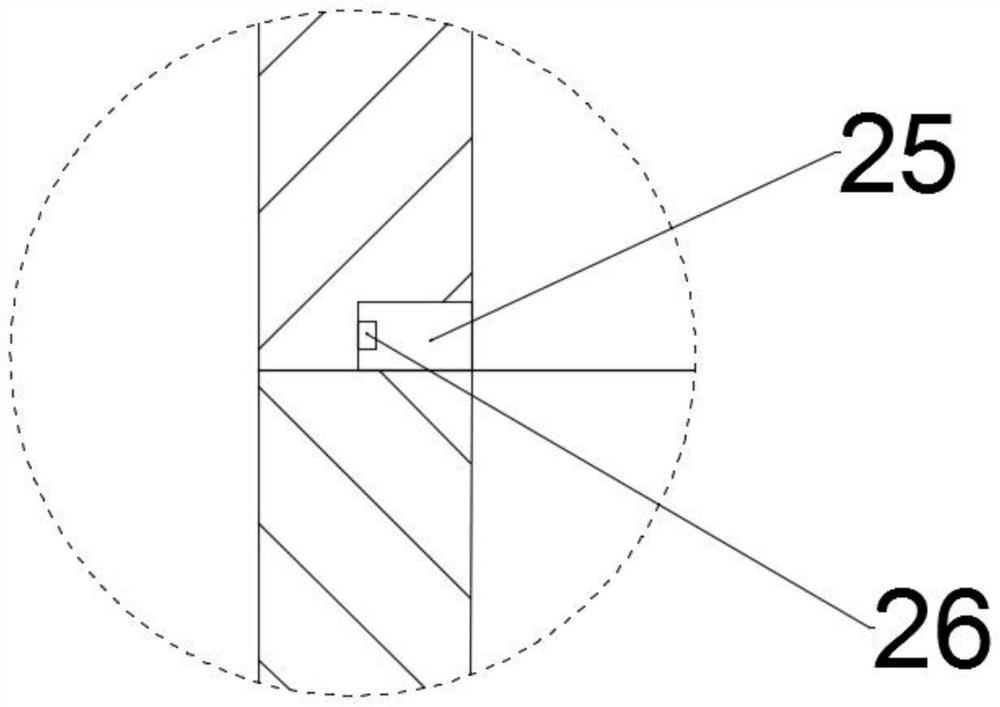

[0027] Such as Figure 1-5 As shown, according to an embodiment of the printing machine with auxiliary paper loading device provided by the present invention, it includes a printing machine housing 20, a paper loading slot 17, and an automatic paper loading mechanism, and the automatic paper loading mechanism includes a paper storage assembly , paper neat transport assembly, paper pushing assembly, the paper storage assembly is located on one side of the printing machine housing 20, the paper neat transport assembly is located between the paper storage assembly and the printing machine housing 20, and the paper pushing assembly is fixed on the printing machine On the machine shell 20 close to the paper loading slot 17, the paper stored by the paper storage component is quantitatively transported by the pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com