High-temperature high-pressure tensile stress strain system of oil well cement and test method thereof

A high temperature and high pressure, oil well cement technology, which is applied in the direction of using stable tension/pressure to test the strength of materials, thermometers, measuring devices, etc. Can't use measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

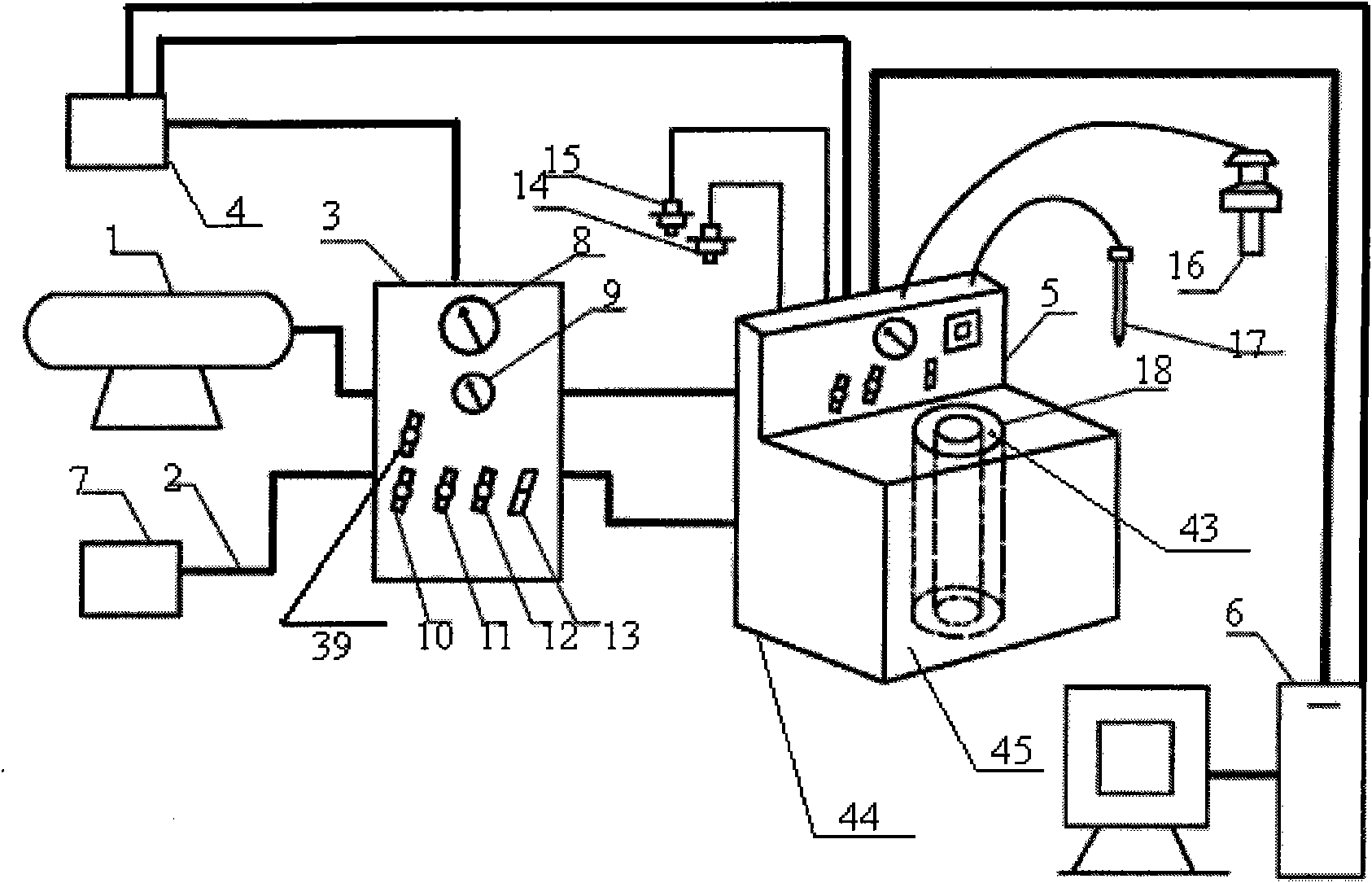

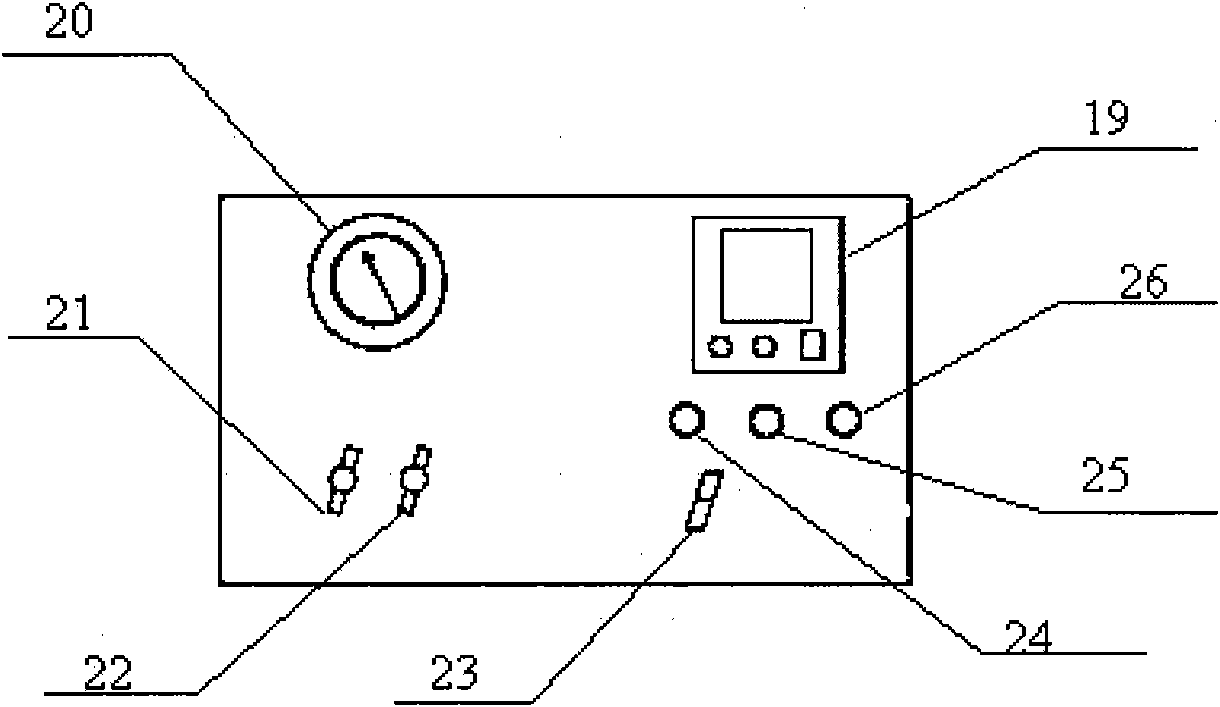

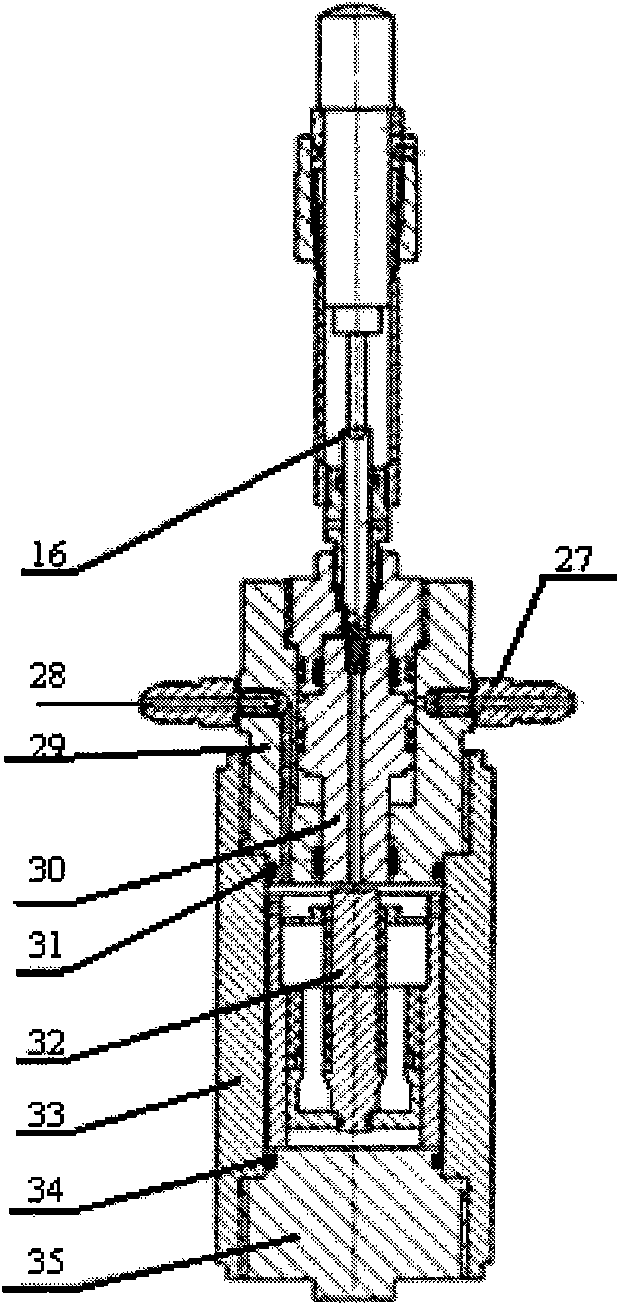

[0061] figure 1 It is the high temperature and high pressure tensile stress and strain system diagram of oil well cement, in which: air compressor 1, pipeline system 2, pressure control unit 3, power supply 4, physical parameter control module panel 5, signal analysis control processing module 6, water source 7, output Pressure gauge 8, input pressure gauge 9, water source valve 10, high pressure output valve 11, pressure rate regulating valve 12, power switch 13, maintenance pressure hose 14, pressure head pressure hose 15, displacement sensor 16, thermocouple 17 , Heating kettle jacket 18, pressure regulating valve 39, heating kettle jacket hole 43, oil well cement high temperature and high pressure tensile stress strain gauge 44, and operating table 45.

[0062] The power supply 4 is connected to the pressure control unit 3, the oil well cement high temperature and high pressure tensile stress strain gauge 44, and the signal analysis control processing module 6; the air com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com