Sterilizing device for biosafety cabinet

A technology of biological safety cabinet and sterilization device, which is applied to water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problem of insufficient atomization of sterilization devices, insufficient spraying of sterilization reagents, and inability to replace sterilization in time. Reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

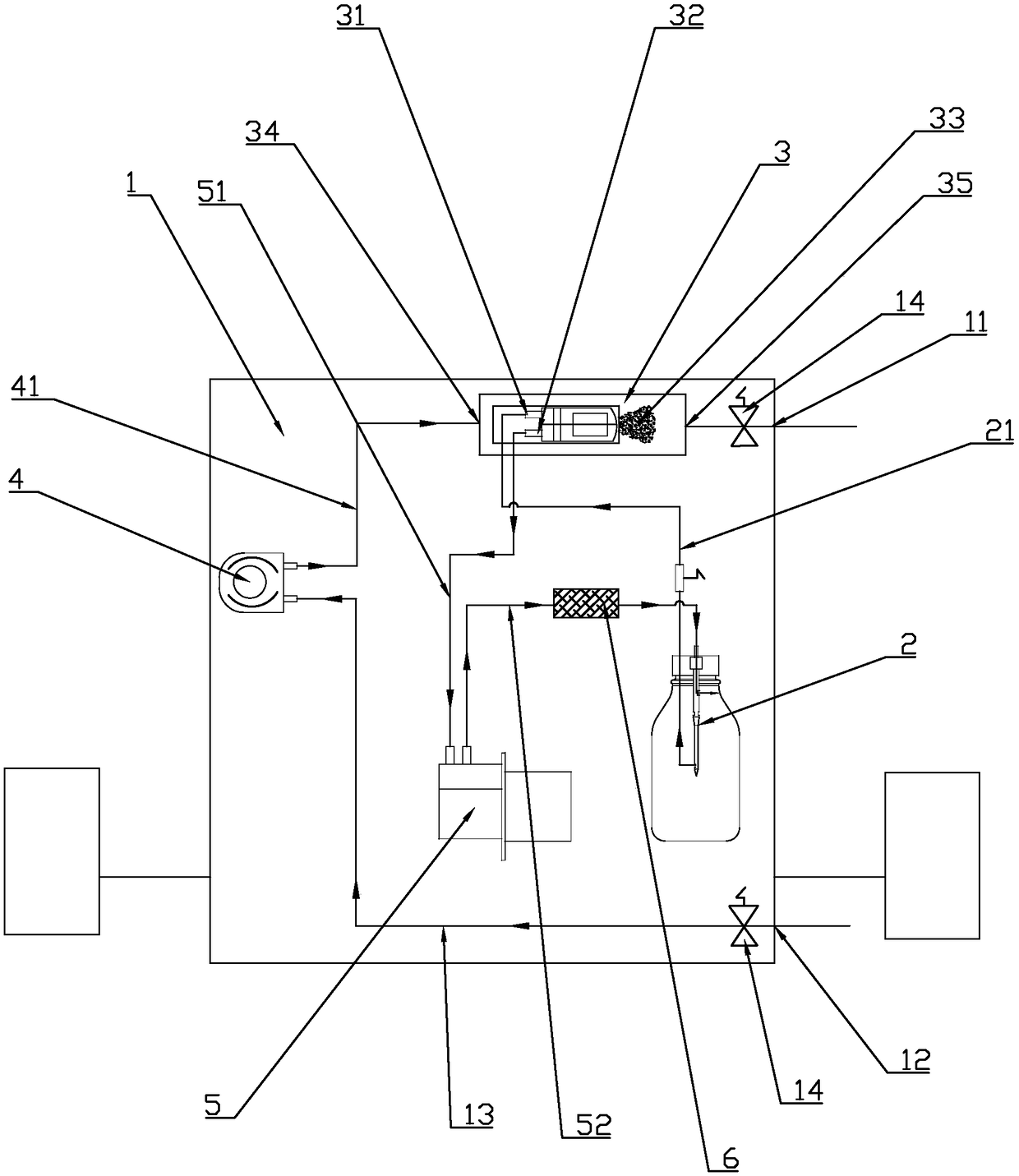

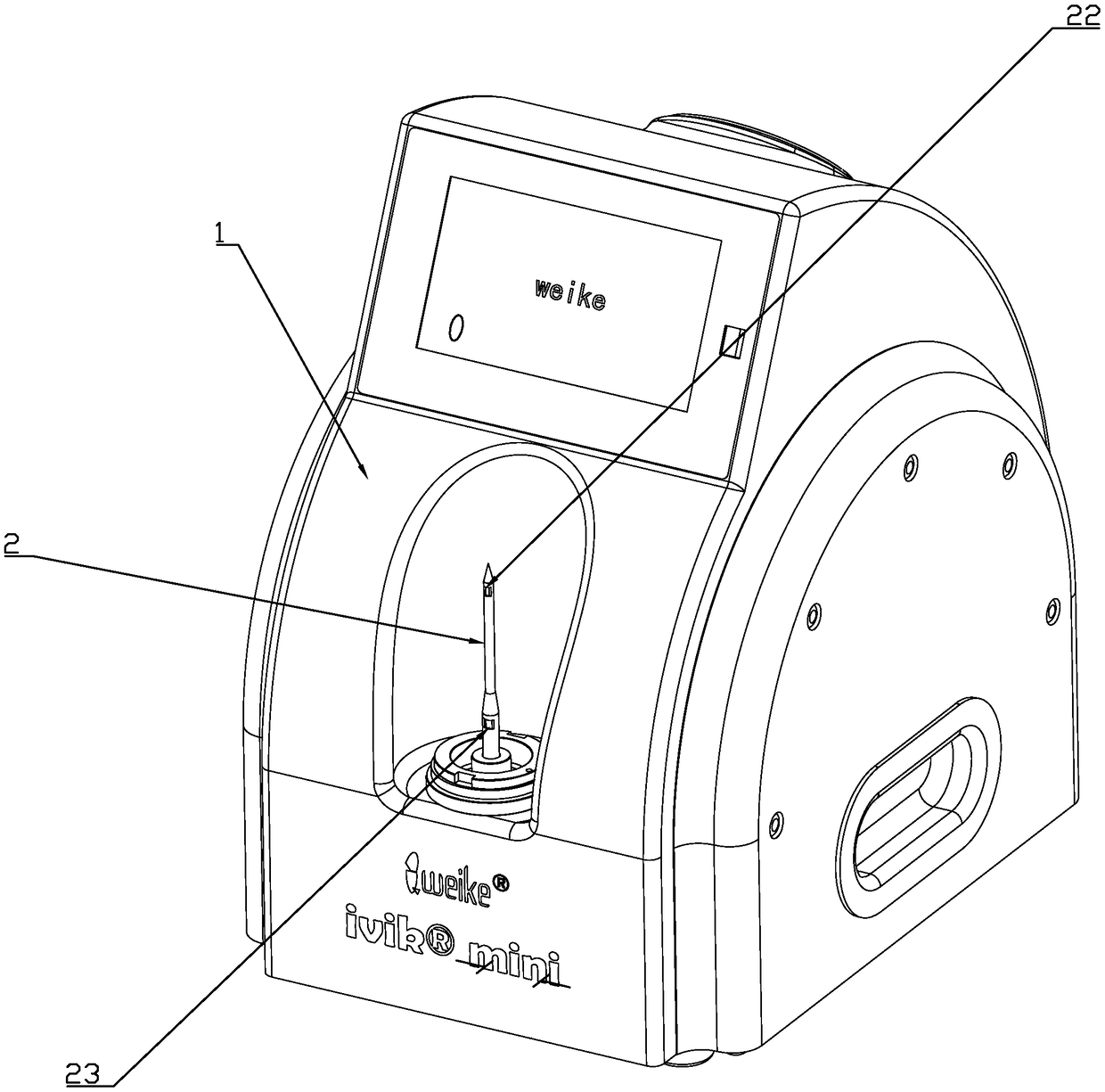

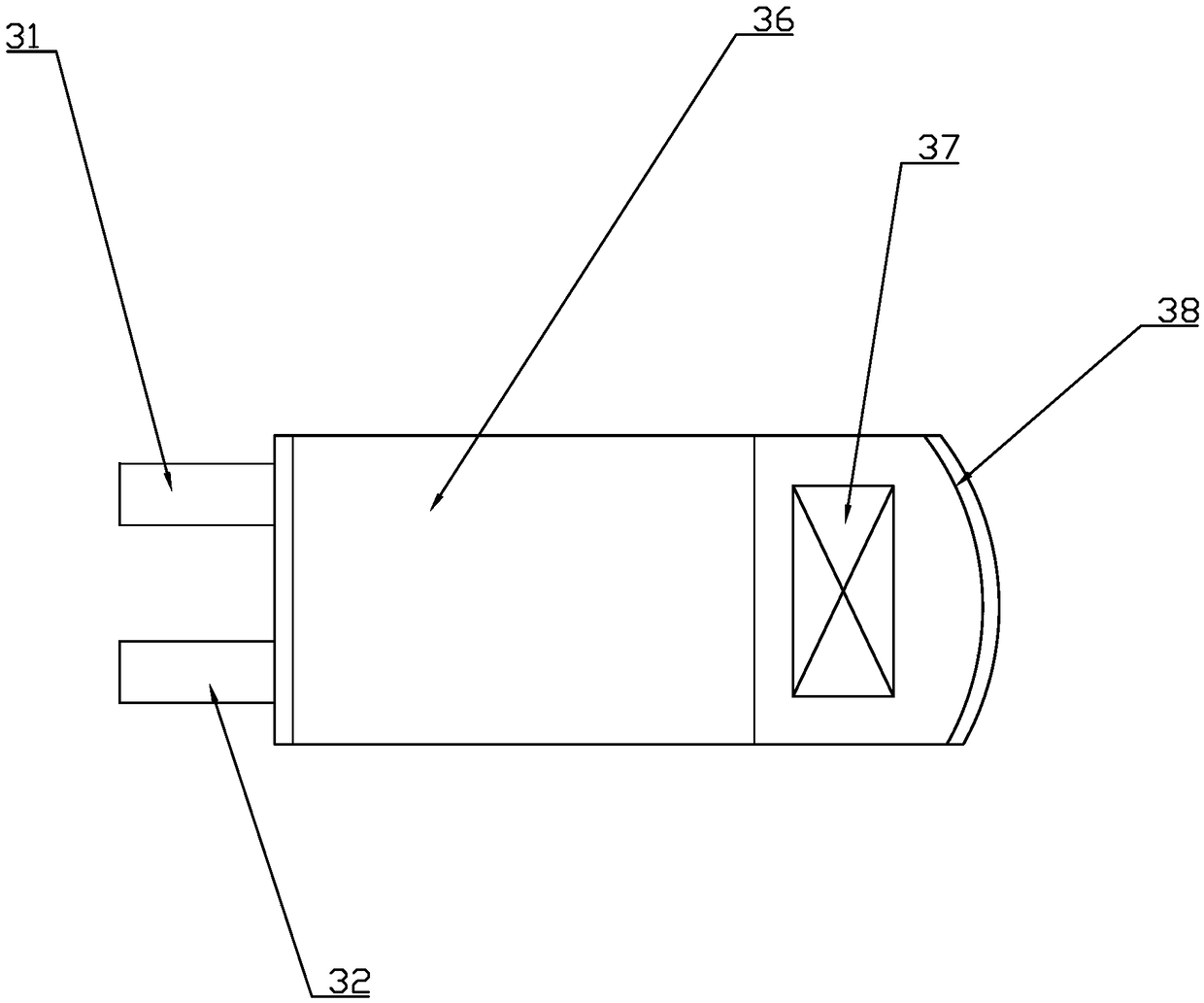

[0025] Depend on Figure 1 to Figure 7 Disclosed is a biosafety cabinet sterilizing device, which includes a housing 1, and the housing 1 is provided with an object stage, and the object stage is provided with a liquid suction needle 2 for extracting a sterilizing reagent. The housing 1 is provided with a cold evaporator 3, a blower 4 and a quantitative pump 5 providing a power source for extraction. One end of the cold evaporator 3 is provided with a liquid inlet 31 and a liquid return port 32, and the other end is provided with a nozzle 33. The liquid suction needle 2 is connected with a liquid inlet pipe 21, and the liquid inlet pipe 21 is connected with the liquid inlet 31. After being extracted by the liquid suction needle 2, the sterilized liquid enters the cold evaporator through the liquid inlet pipe 21 and the liquid inlet 31. 3 is atomized and then evaporated. The quantitative pump 5 is arranged between the cold evaporator 3 and the liquid suction needle 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com