Spindle head device capable of realizing closed-loop control of shoulder and welding pin in stationary shoulder friction stir welding technology

A technology of friction stir welding and static shaft shoulder, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problem of unstable welding process and achieve the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

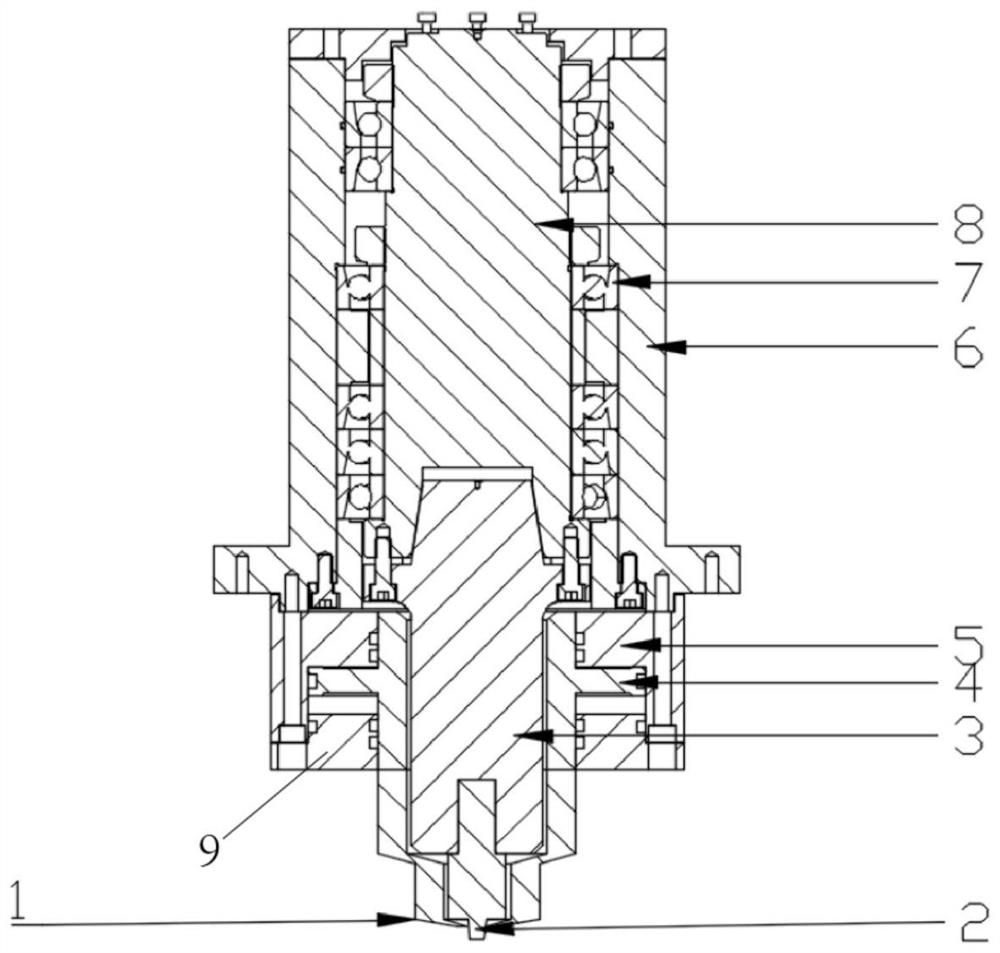

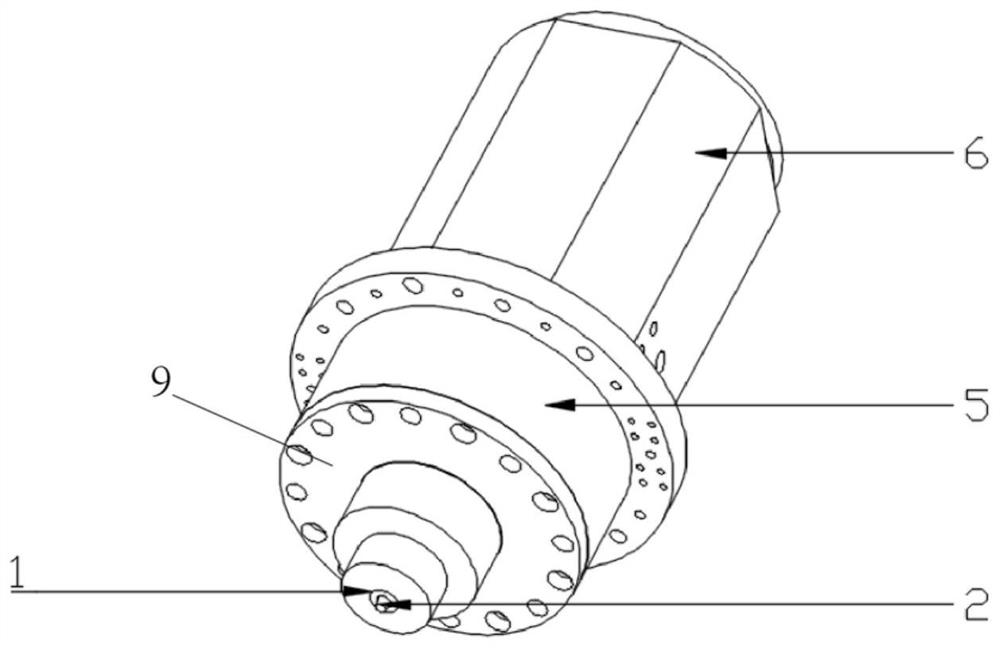

[0024] It can realize the static shoulder friction stir welding technology, and the closed-loop control of the shoulder and the stirring needle can control the spindle head device, including the clamping system, the hydraulic system and the static shoulder 1,

[0025] The clamping system includes a main shaft housing 6, a main shaft 8, a knife handle 3 and a stirring needle 2. The main shaft housing 6 adopts a hollow structure, and the main shaft 8 is arranged in the main shaft housing 6 through a bearing group 7. 3 is connected with the head end of the stirring needle 2;

[0026] The hydraulic system includes a piston rod 4 and an oil cylinder 5. The head end of the cylinder 5 is fixedly connected to the tail end of the main shaft housing 6. The piston rod 4 is arranged in the housing of the oil cylinder 5. The tail end of the piston rod 4 runs through the cylinder head 9 and the The head ends of the stationary shoulder 1 are connected, and the piston rod 4 can move up and do...

Embodiment 2

[0028] On the basis of Embodiment 1, the number of bearing groups 7 is 2 groups, and the bearing groups 7 are respectively arranged in groups along the main shaft 8 from top to bottom. The lower bearing set 7 has four bearings.

[0029] The bearing adopts angular contact bearing.

[0030] An outer spacer and an inner spacer are sequentially arranged between adjacent bearings from outside to inside.

[0031] A tight locking nut for fixing the bearing is arranged at the rear end of the bearing at the rearmost end.

Embodiment 3

[0033] On the basis of the second embodiment, the rear end of the stirring needle 2 is provided with a top wire hole for fixing the stirring needle 2 and the knife handle 3 , and the top wire passes through the top wire hole to connect the stirring needle 2 and the knife handle 3 .

[0034] The outer diameter of the stationary shoulder 1 is equal to the outer diameter of the piston rod 4, the inner diameter of the stationary shoulder 1 is greater than or equal to the maximum outer diameter of the stirring needle 2, and the stirring needle 2 runs through the stationary shoulder 1 and extends out of the stationary shoulder 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com