Variable frequency pump-control-motor closed circuit based on energy regulation

A motor closed-type, energy-adjusting technology, applied in servo motors, servo motor components, fluid pressure actuators, etc., can solve problems such as poor low-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

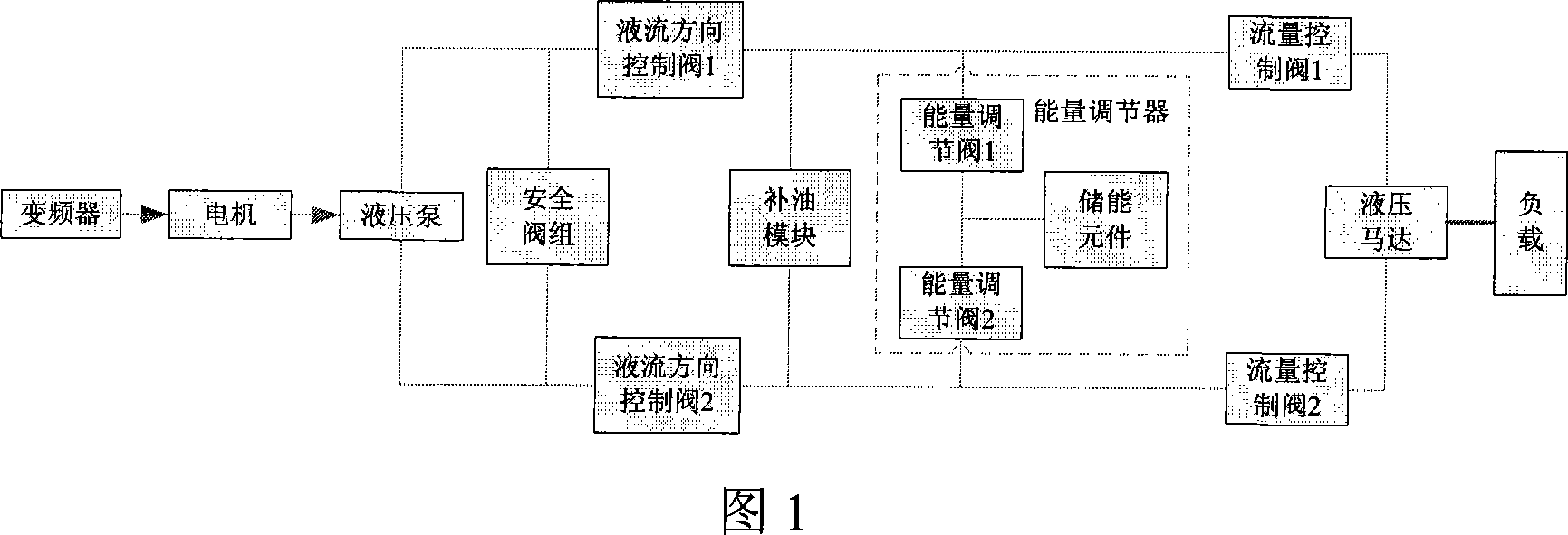

[0020] As shown in Figure 1, the present invention includes a frequency converter, a motor, a hydraulic pump, a safety valve group, an oil replenishment module and a hydraulic motor; The module and the hydraulic motor, the hydraulic motor is connected with the load; it is characterized in that: the energy regulator is bridged between the main circuit between the oil supply module and the hydraulic pump, and the upper and lower main circuits between the safety valve group and the oil supply module are connected respectively The flow control valve is connected to the upper and lower main circuits between the energy regulator and the hydraulic motor respectively.

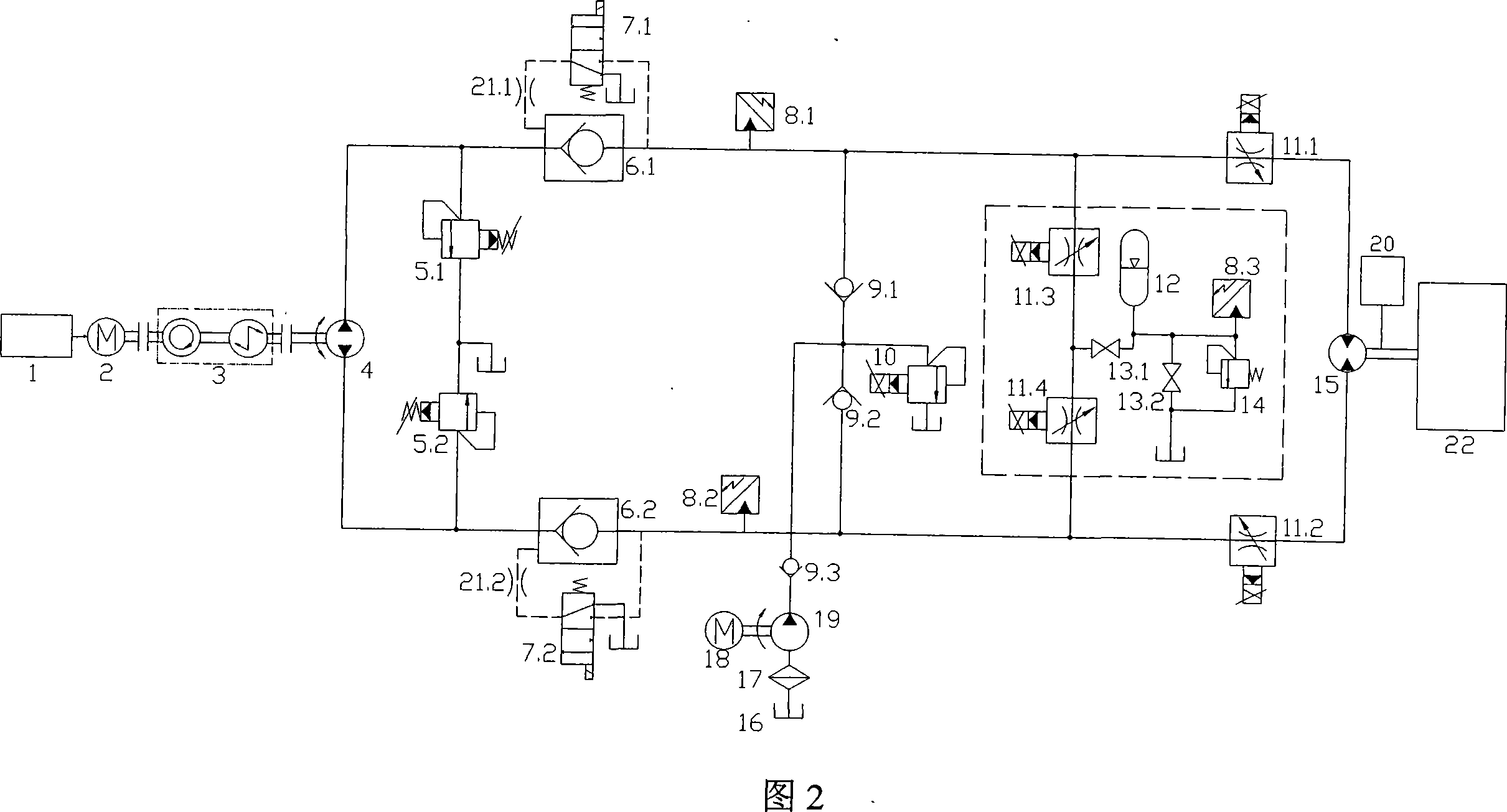

[0021] As shown in Fig. 1 and Fig. 2, the safety valve group is composed of two electromagnetic overflow valves 5.1 and 5.2 connected in series. The two liquid flow directional control valves: have the same str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com