Hydraulic brake valve of feedback piston of valve core

A hydraulic brake valve and valve core technology, applied in valve devices, safety valves, multi-way valves, etc., can solve the problems of increasing the compression amount, increasing the stroke of the push rod, large rigidity, etc., and achieves low braking control force and structure. The effect of simplicity and reduced manipulation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

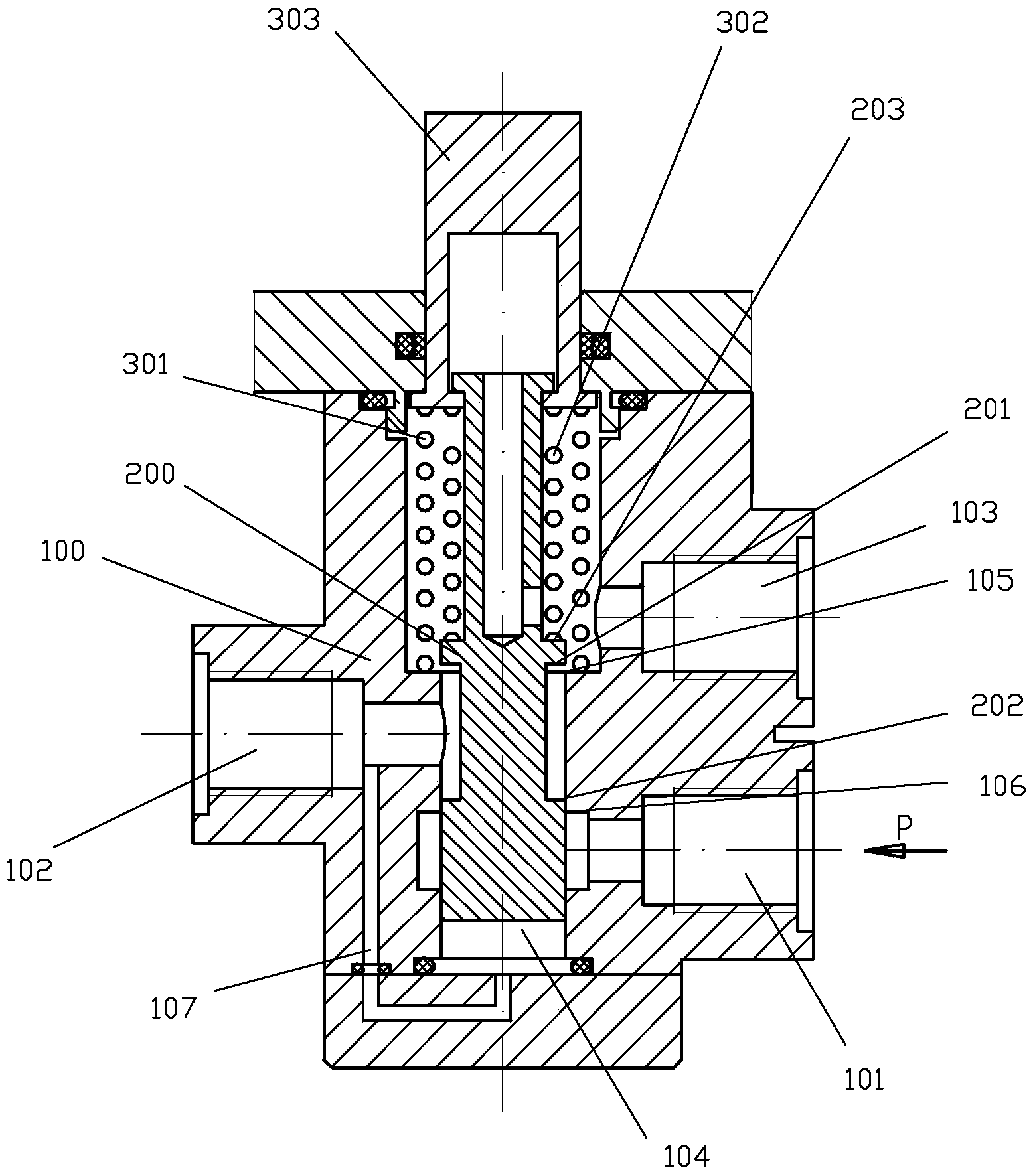

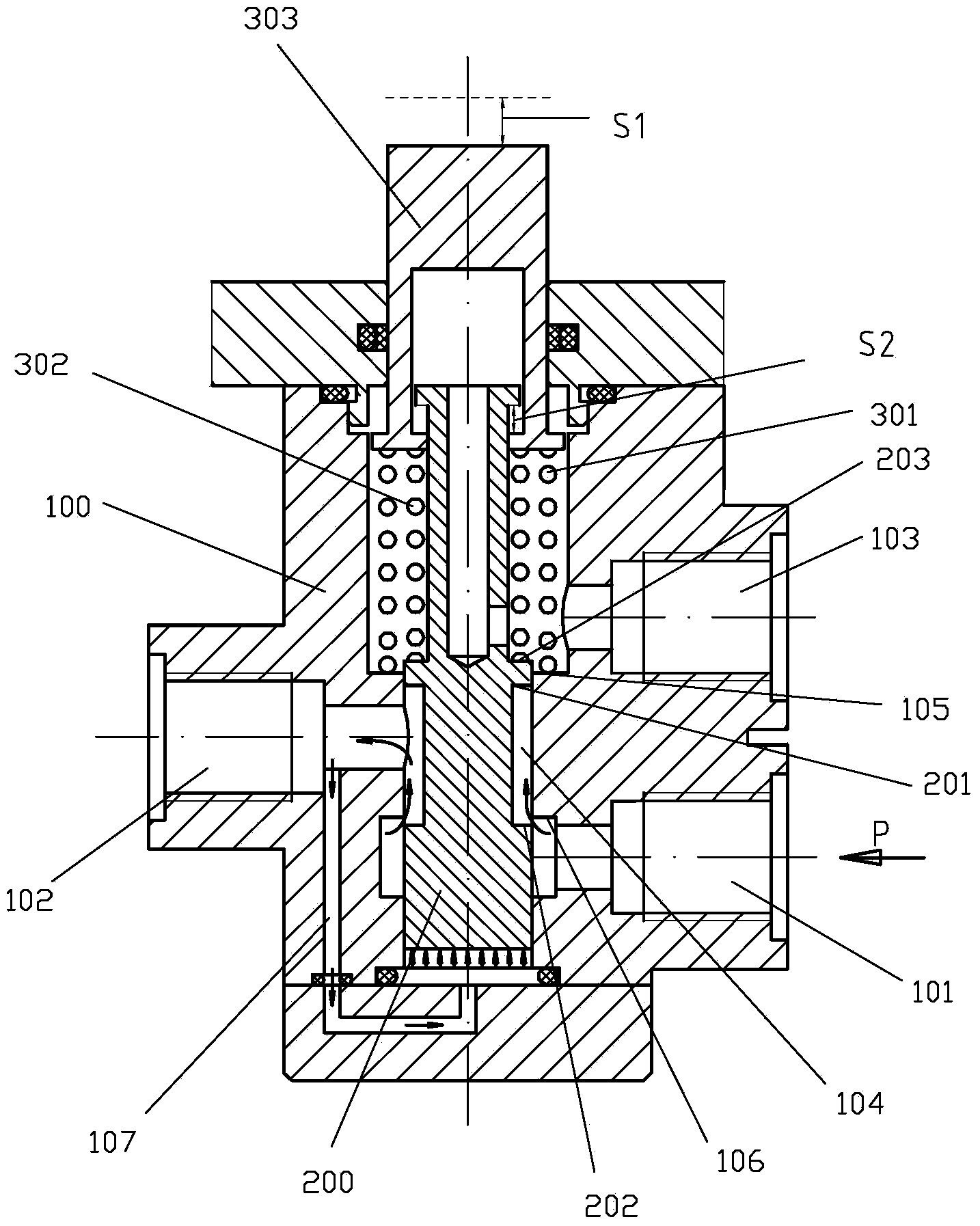

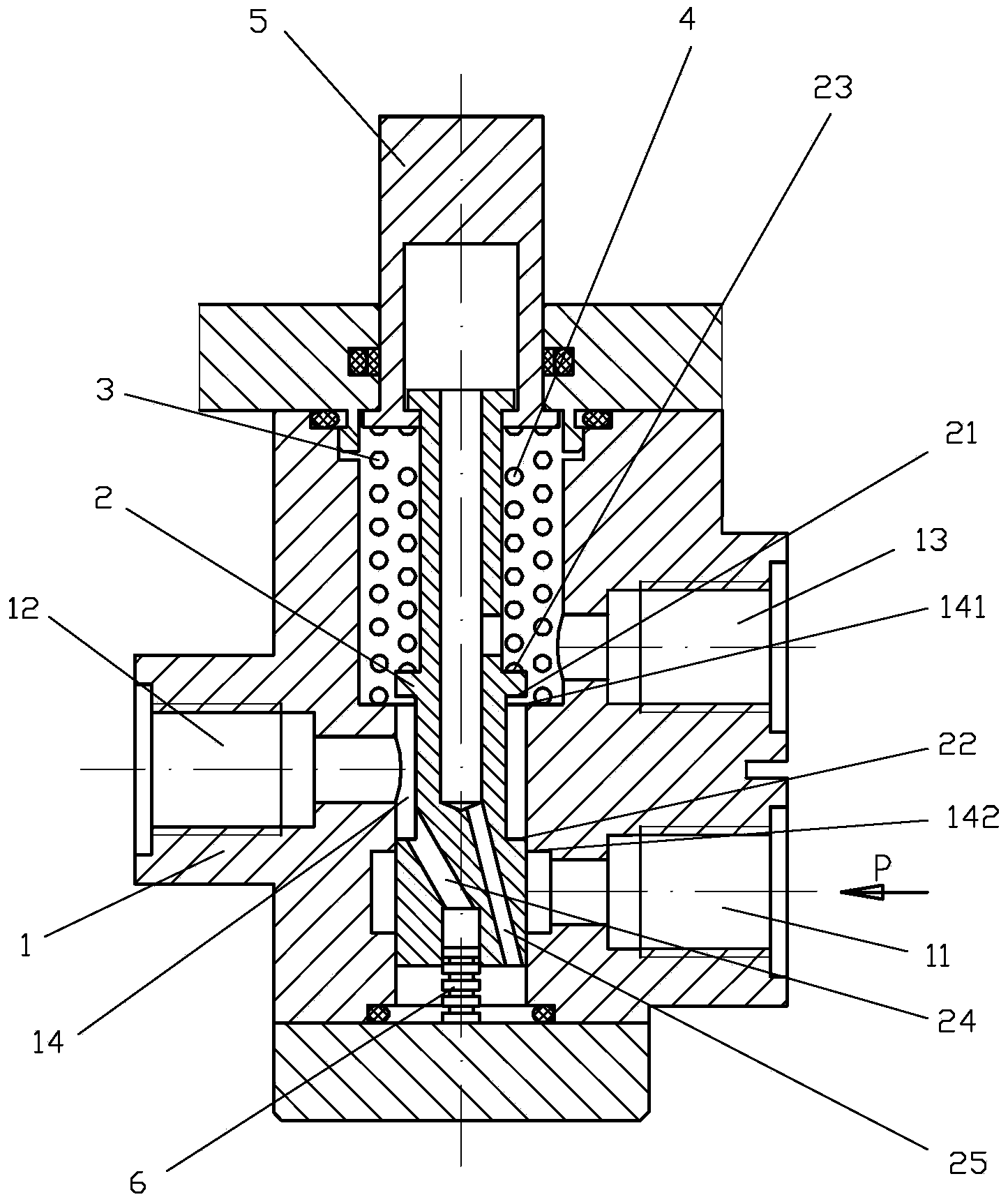

[0015] Examples, see Figure 3 to Figure 4 As shown, the spool feedback piston hydraulic brake valve of the present invention includes a valve body 1, a spool 2, a return spring 3, a balance spring 4, and a push rod 5. The valve body 1 has an input port 11 and an output port 12. The oil return port 13 and the valve core cavity 14, the input port 11, the output port 12, and the oil return port 13 are respectively communicated through the valve core cavity 14. The valve core 2 is slidingly connected in the valve core cavity 14, and the push rod 5 It is movably connected to the upper end of the valve core 2; the valve core cavity 14 is respectively provided with a first annular groove edge 141 and a second annular groove edge 142, and the valve core 2 is respectively provided with a first shoulder 21 and a second shoulder 22 and the third shoulder 23, the balance spring 4 is elastically stretched between the bottom end of the push rod 5 and the third shoulder 23 of the valve core,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com