Battery pack thermocompressor

A technology for hot presses and battery packs, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of high cost, poor effect, complex structure, etc., and achieve the effects of easy maintenance, convenient use, and stable pressure output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

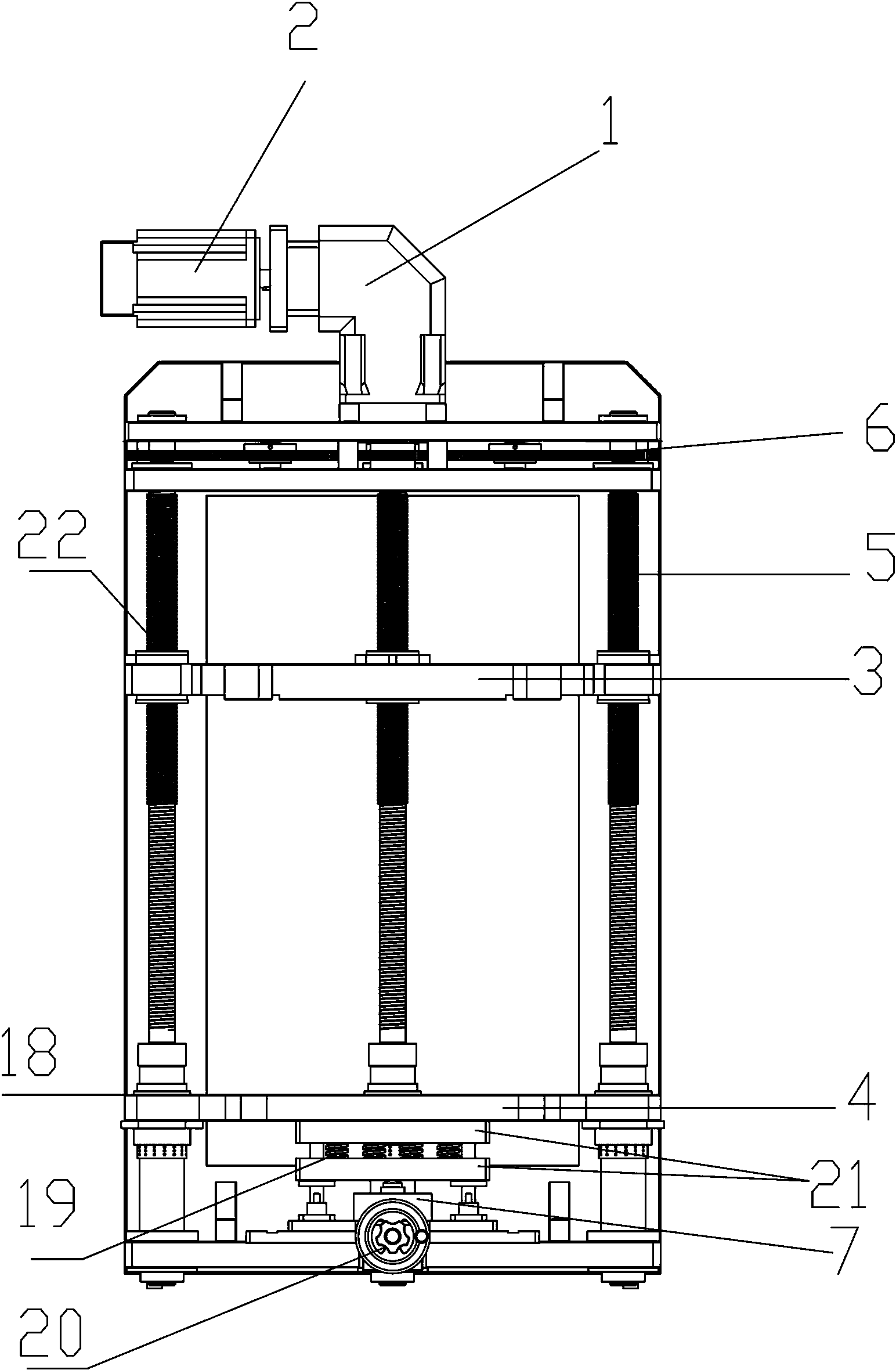

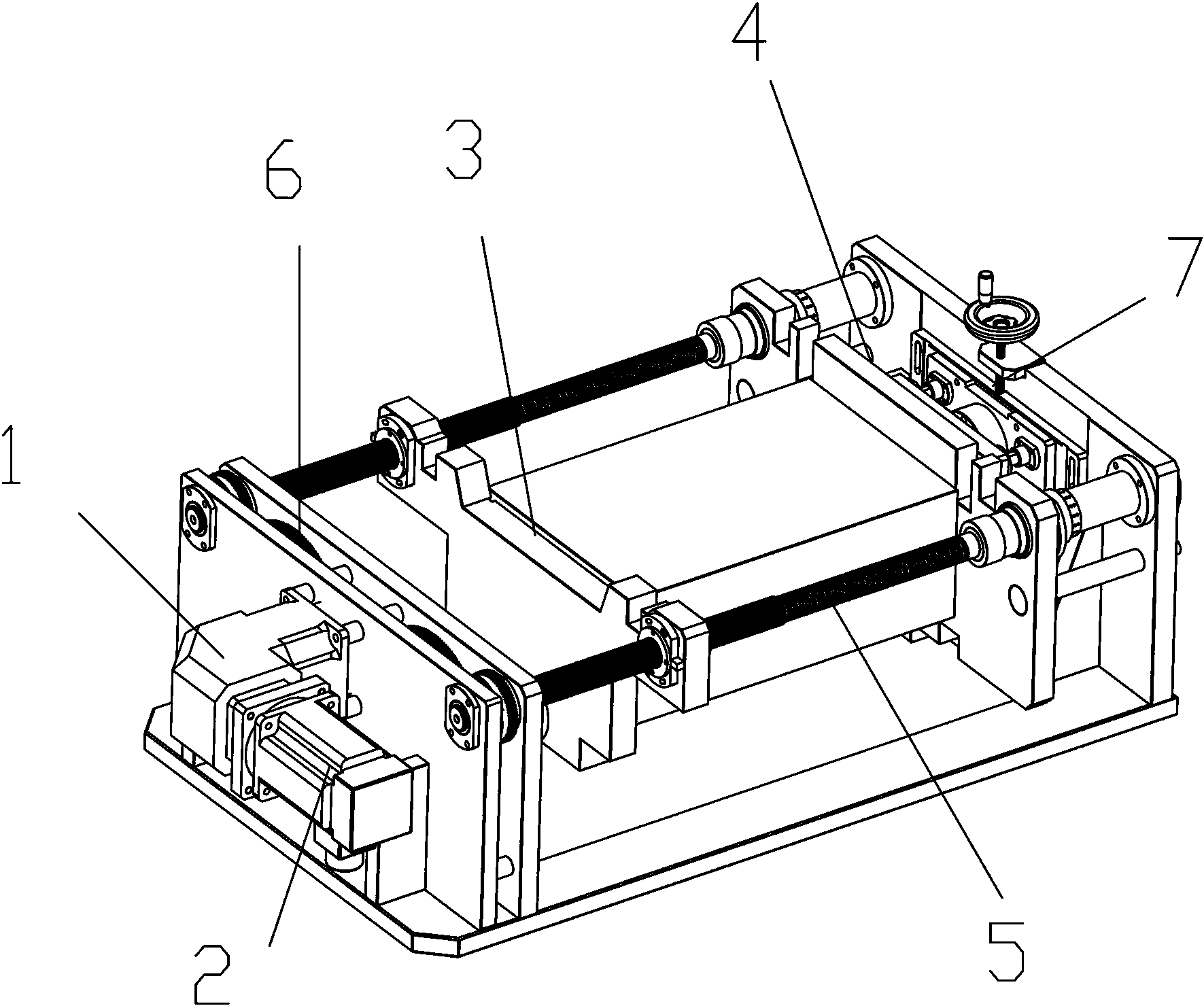

[0019] The structure of the present invention is as figure 1 -3 shows: a battery pack hot press, including a body 18, on which a transmission 1 and a motor 2 are arranged, the transmission 1 cooperates with a gear transmission mechanism 6, and a head plate 3 and a tail plate are arranged in the body 18 4. The head plate 3 is assembled on three lead screws 5 through screw transmission. One end of the lead screw 5 is matched with the gear transmission mechanism 6, and the other end is connected with the body 18. A damping plate 21 is provided under the tail plate 4. A spring 19 is arranged between the vibrating plates 21 , and the pressure sensor 7 cooperates with the damping plate 21 below the springs 19 .

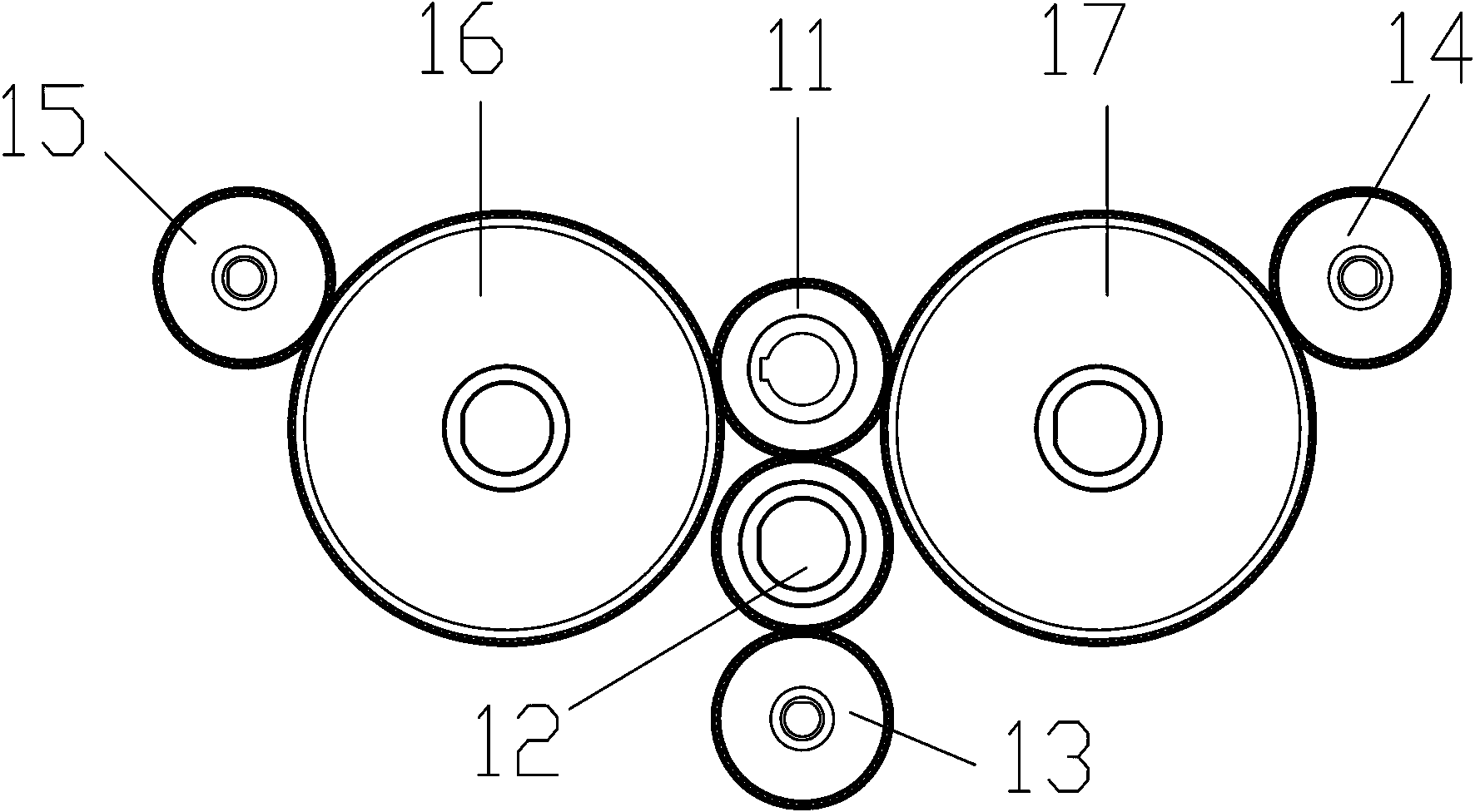

[0020] The detailed structure of gear transmission mechanism of the present invention is as figure 2 As shown, the gear transmission mechanism 6 includes a driving gear 11, the driving gear 11 cooperates with the speed changer 1 through a transmission shaft, the driving g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com