Axial vibration power-type piezoelectric ceramic transformer

A piezoelectric ceramic, axial vibration technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of piezoelectric ceramics. Transformer performance, piezoelectric ceramic transformer overheating, weak thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

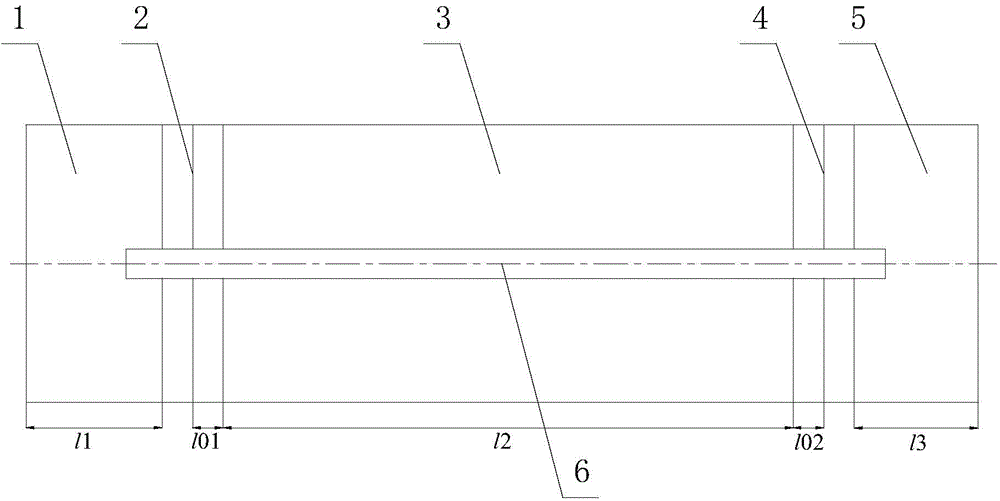

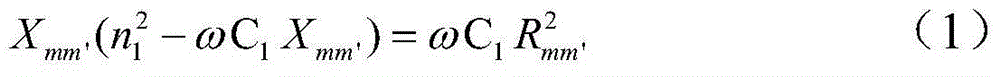

[0039] The first metal cylinder 1, the second metal cylinder 3 and the third metal cylinder 5 are all made of duralumin material, and their radii are equal to R respectively. 1 =R 2 =R 3 =0.01m, l 1 = l 2 = l 3 =0.02m; input the radius r of piezoelectric ceramic body 2 1 = 0.01m, which is composed of 2 thickness l 01 = 0.006m piezoelectric ceramic sheets are laminated, and the radius r of the output piezoelectric ceramic body 4 2 = 0.01m, which is composed of 2 thickness l 02 = 0.006m piezoelectric ceramic sheets laminated; where l 1 +l 2 +l 3 +2l 01 +2l 02 >4R 1 .

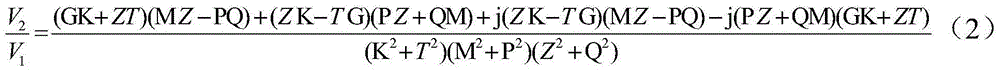

[0040] When the load resistance of the transformer is 50 ohms, using the resonance frequency equation and transformation ratio formula obtained in the present invention, the resonance frequency of the transformer is 25656 Hz, the anti-resonance frequency is 27458 Hz, and the transformation ratio is 1.0002.

Embodiment 2

[0042] The first metal cylinder 1, the second metal cylinder 3 and the third metal cylinder 5 are all made of duralumin material, and their radii are equal to R respectively. 1 =R 2 =R 3 =0.01m, l 1 = l 2 =0.04m, l 3 =0.01m; input the radius r of piezoelectric ceramic body 2 1 = 0.01m, which is composed of 2 thickness l 01 = 0.006m piezoelectric ceramic sheets are laminated, and the radius r of the output piezoelectric ceramic body 4 2 = 0.01m, which is composed of 2 thickness l 02 = 0.006m piezoelectric ceramic sheets are laminated; l 1 +l 2 +l 3 +2l 01 +2l 02 >4R 1 .

[0043] When the load resistance of the transformer is 50 ohms, using the resonance frequency equation and transformation ratio formula obtained in the present invention, the resonance frequency of the transformer is 19071 Hz, the anti-resonance frequency is 20283 Hz, and the transformation ratio is 1.728.

Embodiment 3

[0045] The first metal cylinder 1, the second metal cylinder 3 and the third metal cylinder 5 are all made of duralumin material, and their radii are equal to R respectively. 1 =R 2 =R 3 =0.01m, l 1 = l 2 =0.01m, l 3 =0.04m; input the radius r of piezoelectric ceramic body 2 1 = 0.01m, which is composed of 2 thickness l 01 = 0.006m piezoelectric ceramic sheets are laminated, and the radius r of the output piezoelectric ceramic body 4 2 = 0.01m, which is composed of 2 thickness l 02 = 0.006m piezoelectric ceramic sheets are laminated; l 1 +l 2 +l 3 +2l 01 +2l 02 >4R 1 .

[0046] When the load resistance of the transformer is 50 ohms, using the resonance frequency equation and transformation ratio formula obtained in the present invention, the resonance frequency of the transformer is 26211 Hz, the anti-resonance frequency is 27178 Hz, and the transformation ratio is 0.588.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonance frequency | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com