Magnetic-levitation motor pure air-cooling heat dissipation structure with two impellers

A heat dissipation structure and magnetic levitation technology, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of uneven cooling of the stator and poor internal cooling effect of the stator, and achieve improved cooling effect, stable movement, Effect of Simplified Heat Dissipation Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

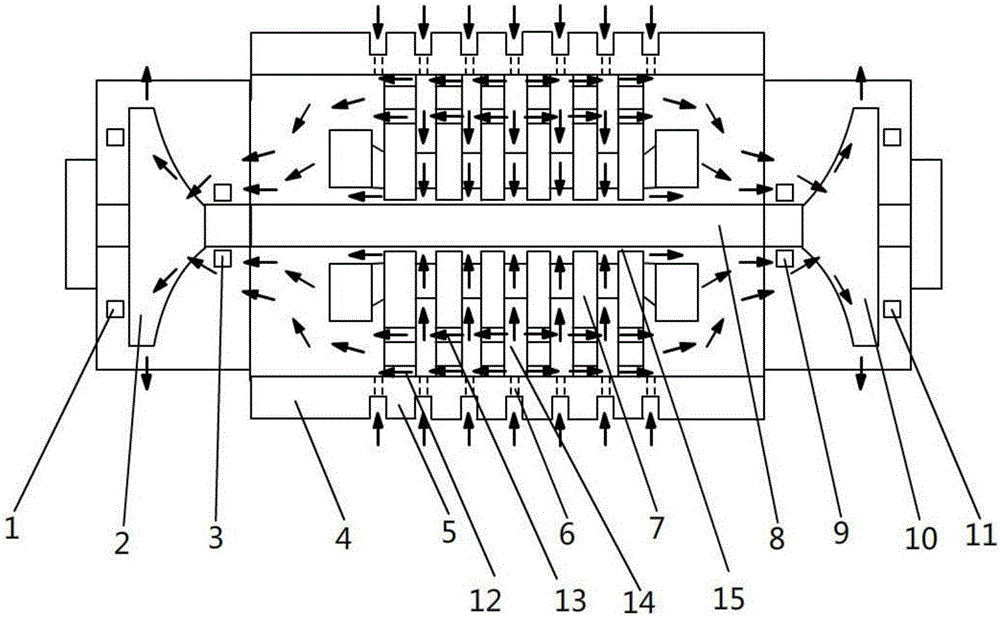

[0030] Embodiment 1: as Figures 1 to 2 As shown, this embodiment is a pure air-cooled heat dissipation structure of a magnetic levitation motor with two impellers, including a front axial bearing 1, a front impeller thrust plate 2, a front radial bearing 3, a casing 4, cooling fins 5, a machine Shell ventilation hole 6, stator 7, rotor 8, rear radial bearing 9, rear impeller thrust disc 10 and rear axial bearing 11.

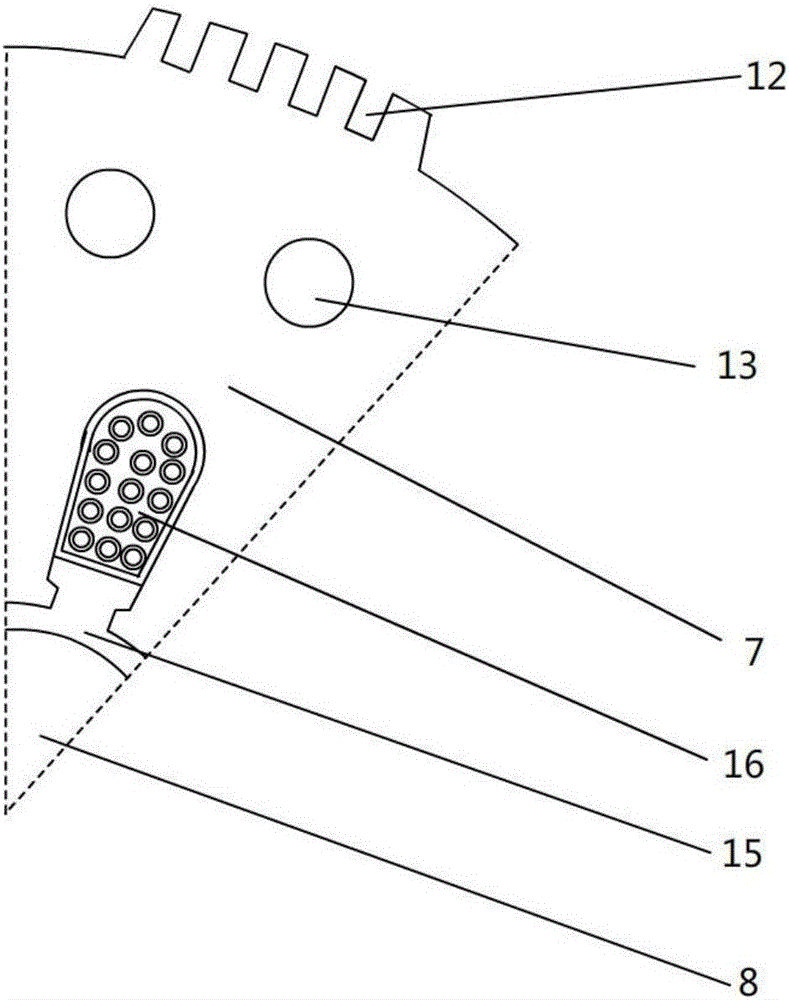

[0031] The stator 7 is provided with an air channel 12 between the stator and the casing. The stator 7 is divided into 5 sections in the axial direction, and each section is arranged side by side in the axial direction to form a stator radial air channel 14. The stator 7 is provided with 2 circular stator axial ventilation holes 13 , The stator axial ventilation holes 13 can increase the heat exchange area of the air duct inside the stator 7 and enhance the cooling effect on the stator 7 . There are 7 casing ventilation holes 6 aligned with the stator radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com