Radial vibration annular piezoelectric ceramic composite transformer

A piezoelectric ceramic and annular piezoelectric technology, which is applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, components and circuits of piezoelectric devices or electrostrictive devices, and can solve the problems affecting piezoelectric ceramics. Transformer performance, weak thermal conductivity, overheating of piezoelectric ceramic transformers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

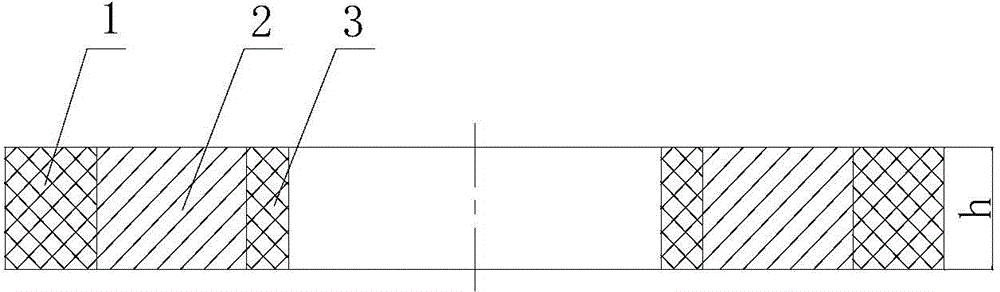

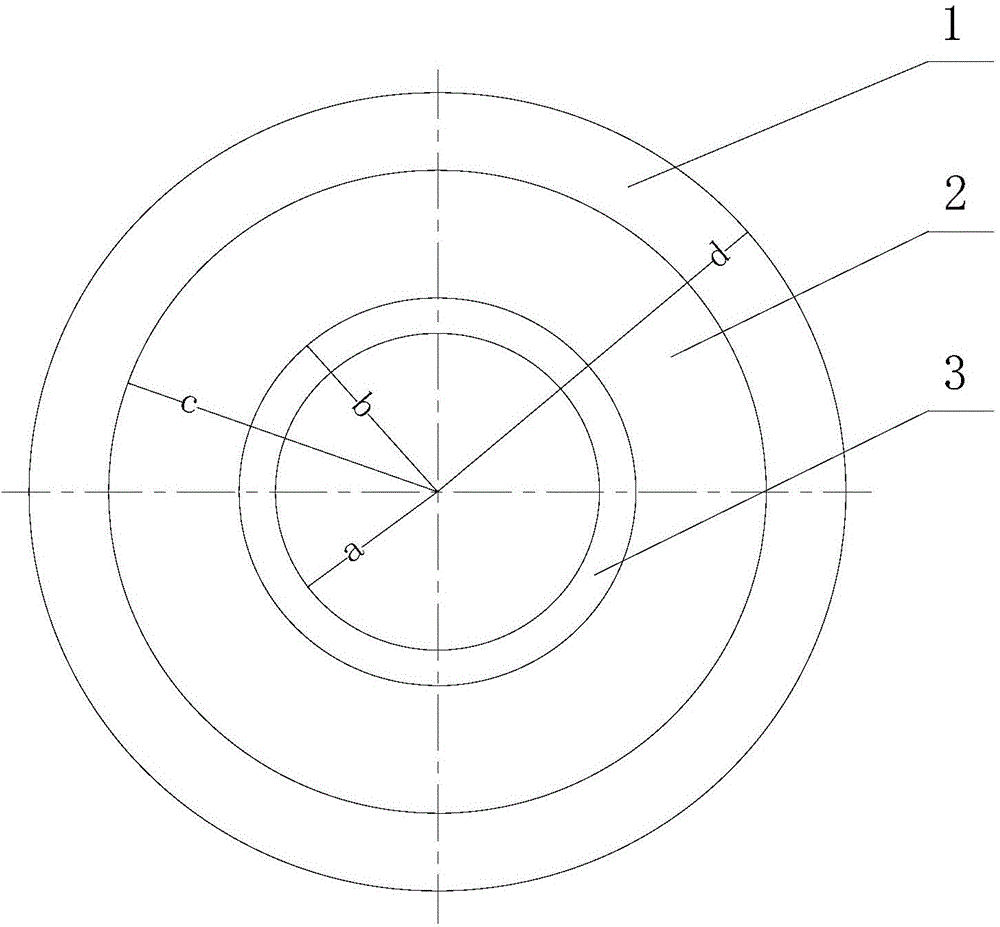

[0066] a=0.01m, b=0.012m, c=0.02m, d=0.024m, h=0.005m, piezoelectric ceramic inner ring 3 and piezoelectric ceramic outer ring 1 are made of PZT-4 material, metal conduction The material of the ring 2 is duralumin, and the load impedance R=50 ohms.

[0067] Utilizing the resonance frequency equation (1) and the voltage gain ratio equation (2), it can be obtained that the operating frequency fr and the anti-resonance frequency fa of the piezoelectric ceramic composite transformer of this embodiment are respectively: fr=39.23kHz, fa=39.74kHz, voltage The gain ratio is M=1.54.

example 2

[0069] a=0.01m, b=0.012m, c=0.02m, d=0.024m, h=0.005m, piezoelectric ceramic inner ring 3 and piezoelectric ceramic outer ring 1 are made of PZT-4 material, metal conduction The material of the ring 2 is duralumin, and the load resistance R=200 ohm.

[0070] Using the resonance frequency equation (1) and the voltage gain ratio equation (2), it can be obtained that the operating frequency fr and the anti-resonance frequency fa of the piezoelectric ceramic composite transformer of this embodiment are respectively: fr=39.46kHz, fa=39.97kHz, the voltage The gain ratio is M=1.57.

example 3

[0072] a=0.01m, b=0.012m, c=0.02m, d=0.026m, h=0.005m, piezoelectric ceramic inner ring 3 and piezoelectric ceramic outer ring 1 are made of PZT-4 material, metal conduction The material of the ring 2 is duralumin, and the load impedance R=50 ohms.

[0073] Utilizing the resonance frequency equation (1) and the voltage gain ratio equation (2), it can be obtained that the operating frequency fr and the anti-resonance frequency fa of the piezoelectric ceramic composite transformer of this embodiment are respectively: fr=36.02kHz, fa=36.42kHz, and the voltage The gain ratio is M=1.69.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com