Method for selecting and preparing raw materials of 550kN-grade suspension-type porcelain insulator glaze

A porcelain insulator, 550kn technology, which is applied in the field of selection and preparation of raw materials for graded suspension porcelain insulator glaze, can solve problems such as non-uniform selection, and achieve the effects of good fluidity, low degree of thickening, and improved bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Following is the concrete process step of implementing the present invention:

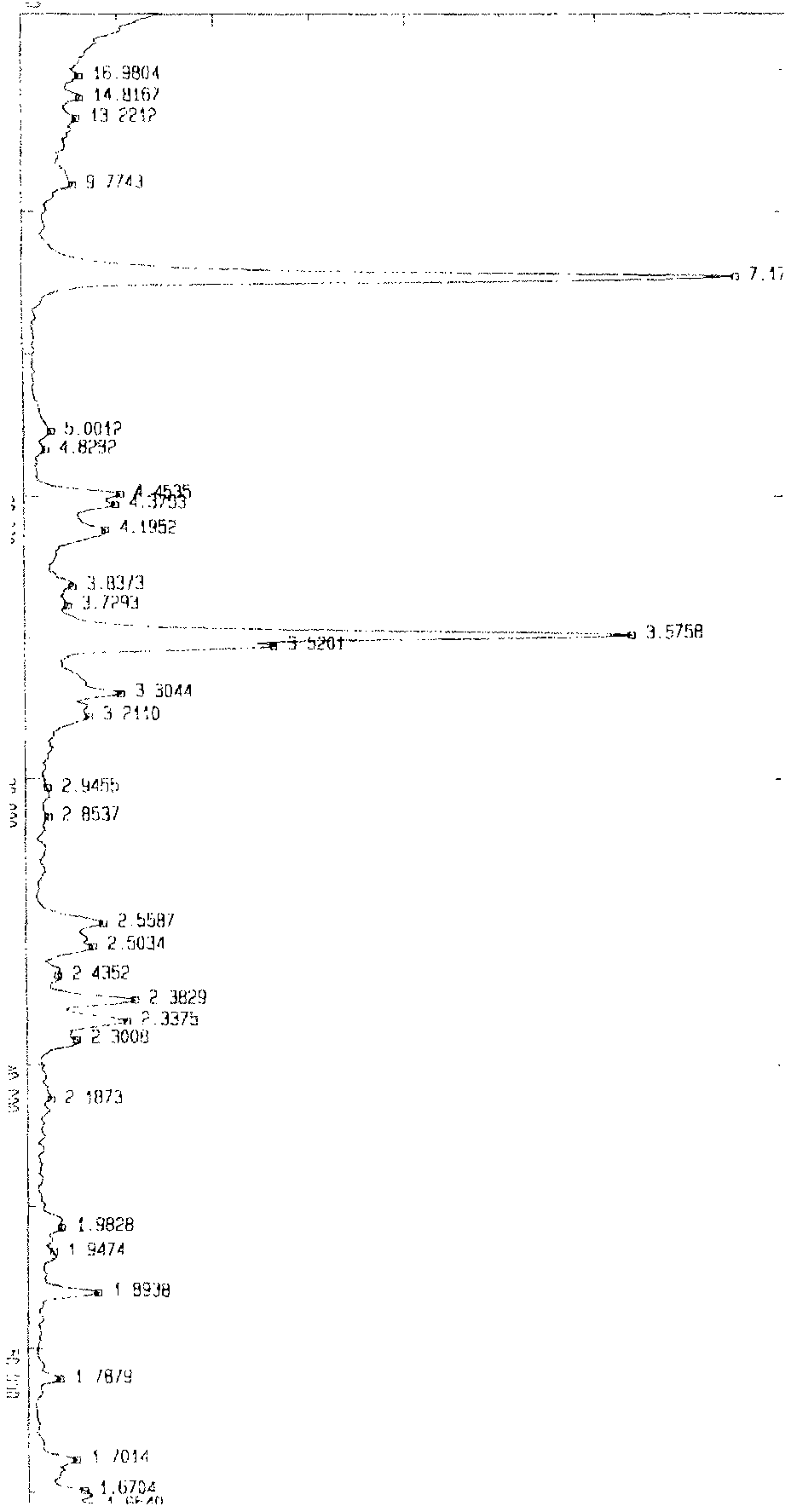

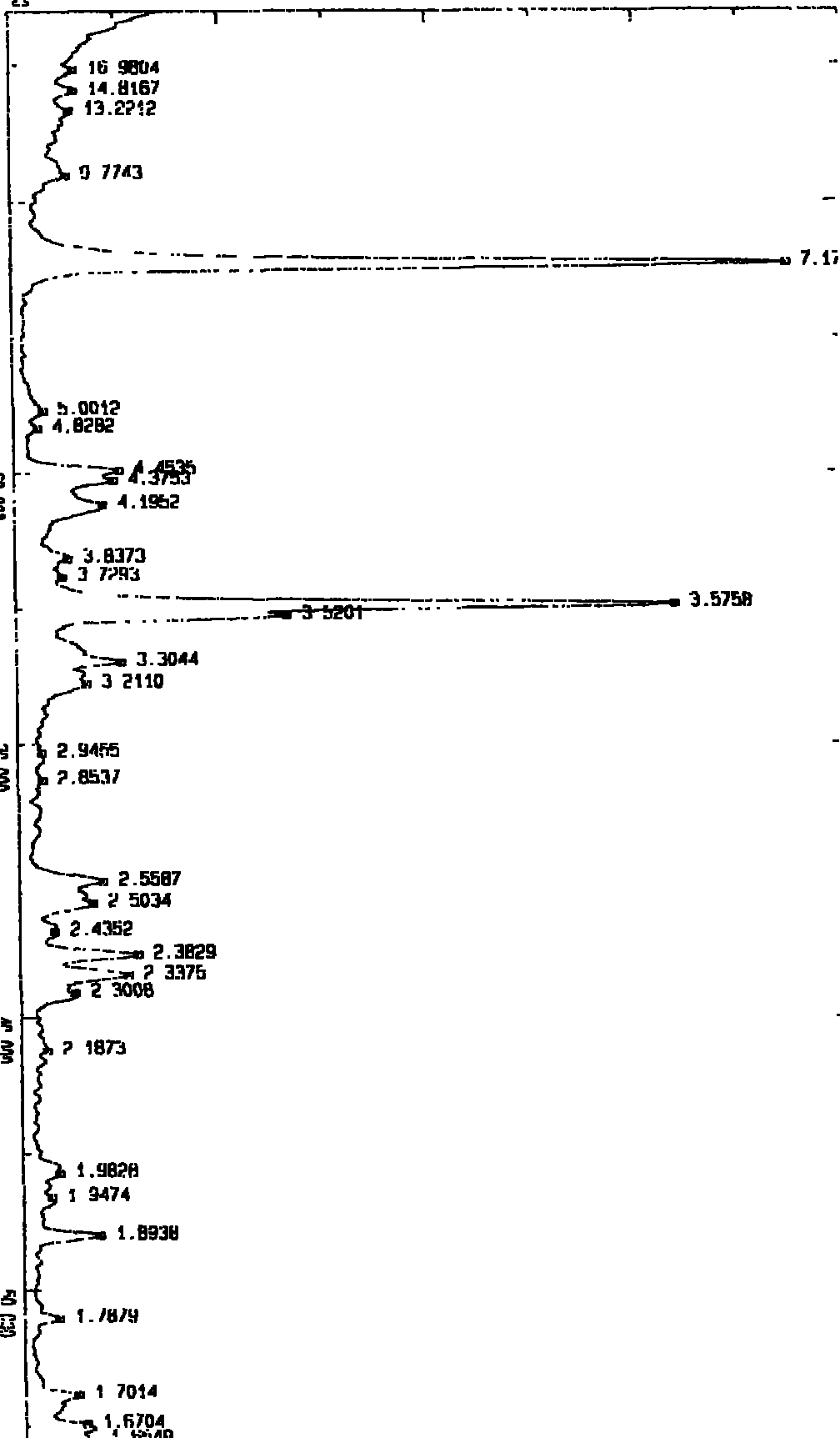

[0022] Firstly, choose kaolinite clay 6-20%, talc 7-15%, feldspar 20-40%, refined quartz 25-40%, calcined bauxite 10-20%, calcium carbonate 3-15%, and porcelain powder 0-10%, water glass 0.001-1%. The particle size of the clay raw material is 20-40 mesh, and the particle size of other raw materials is 180-200 mesh. After uniform mixing, ball milling, and then component analysis. Its compositional analysis data and particle size are expressed as follows:

[0023] Calculation of chemical composition (%)

[0024] SiO 2

[0025] Particle size analysis

[0026] Micron

[0027] Specifically, the preparation is carried out according to the following process steps. The first step: raw material preparation, select kaolinite clay 6-20%, talc 7-15%, feldspar 20-40%, refined quartz 25-40%, calcined bauxite 10-20%, calcium carbonate 3-15%, medium porcelain powder 0-10%, water g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com