Focal length adjustable lens based on dielectric elastomer driver and preparation method thereof

A dielectric elastomer, adjustable technology, applied in lenses, instruments, optics, etc., can solve the problems of the area of the flexible electrode 5 becoming larger and inconsistent, the inability to ensure the same size of the groove, and the poor zoom imaging effect, etc., to achieve zooming. The imaging effect is good, the dielectric constant is improved, and the response speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

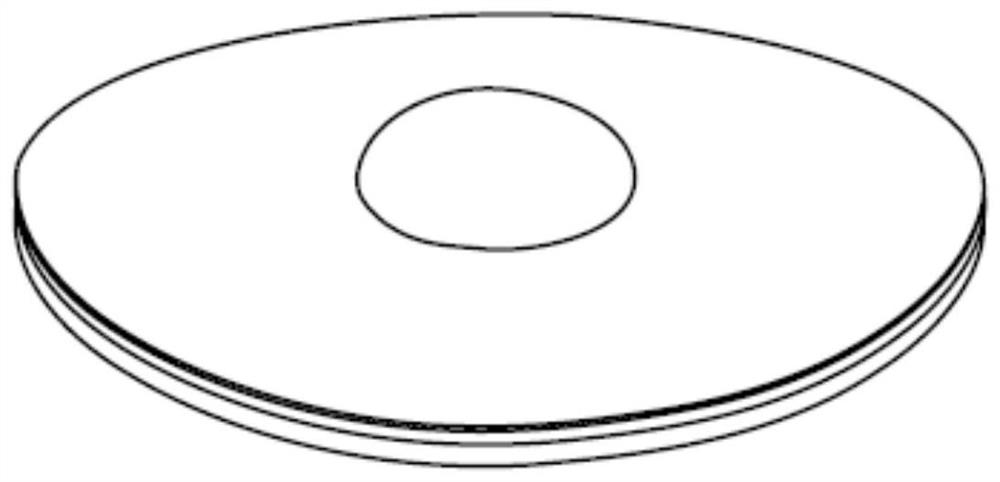

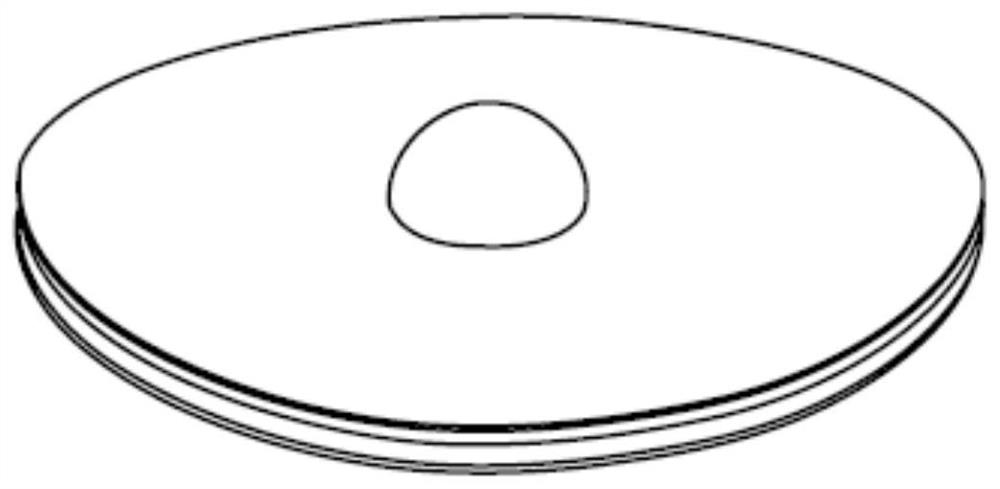

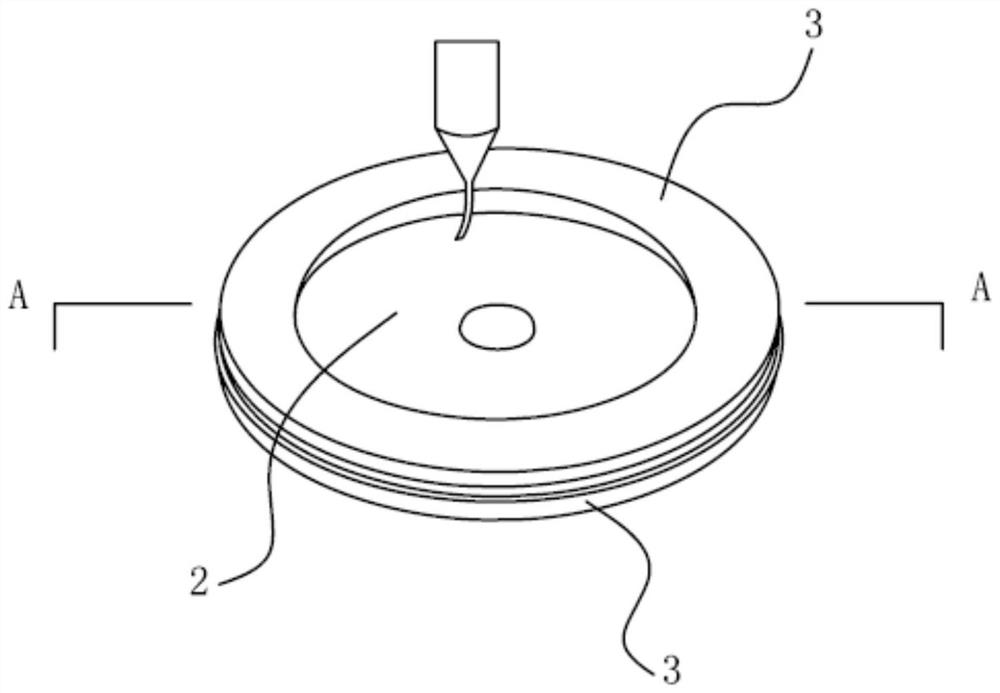

[0036] like figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a focus-adjustable lens based on a dielectric elastomer driver includes a lens body 11, and the dielectric elastomer driver includes a The dielectric elastomer annular film 1 that adjusts the focal length of the lens by controlling the radius of curvature of the lens body 11, the flexible electrodes 2 arranged on the upper and lower surfaces of the dielectric elastomer annular film 1, and the dielectric elastomer annular film after pre-stretching The upper and lower surfaces of the membrane 1 are symmetrically arranged along the edge of the dielectric elastomer annular membrane 1 and are used for fixing and supporting the ring frame 3 . Wherein, the electrode material can be graphite powder, carbon nanotubes, and nano silver. In this embodiment, the flexible electrode adopts conductive carbon grease, and the material of the ring frame 3 is plexiglass, and the ring frame 3 is fixed on the dielectric elastomer ring by pasting. f...

Embodiment 2

[0052] A method for preparing a focal length adjustable lens based on a dielectric elastomer driver, comprising the steps of:

[0053] (1) Copper phthalocyanine particles are dispersed in n-heptane and ultrasonically treated to obtain a copper phthalocyanine-n-heptane mixture, and then the mixture is added to a two-component silicone rubber solution and stirred to obtain a silicone rubber ink, Standby; wherein, the ultrasonic treatment time is 6min, the stirring method is magnetic stirring, and the stirring time is 12min.

[0054] (2) Using electrojet printing technology, first print the lower layer of transparent silicone rubber film body, then use the silicone rubber ink obtained in step (1) to print along the circumference of the lower layer of transparent silicone rubber film body to obtain a dielectric elastomer annular film, and then move To an oven, dry and solidify to obtain a dielectric elastomer; set the temperature of the oven to 110° C., and dry for 1.5 hours until...

Embodiment 3

[0060] A method for preparing a focal length adjustable lens based on a dielectric elastomer driver, comprising the steps of:

[0061] (1) Copper phthalocyanine particles are dispersed in n-heptane and ultrasonically treated to obtain a copper phthalocyanine-n-heptane mixture, and then the mixture is added to a two-component silicone rubber solution and stirred to obtain a silicone rubber ink, Standby; wherein, the ultrasonic treatment time is 8 minutes, the stirring method is magnetic stirring, and the stirring time is 15 minutes.

[0062] (2) Using electrojet printing technology, first print the lower layer of transparent silicone rubber film body, then use the silicone rubber ink obtained in step (1) to print along the circumference of the lower layer of transparent silicone rubber film body to obtain a dielectric elastomer annular film, and then move to an oven for drying and curing to obtain a dielectric elastomer; the temperature of the oven is set to 120° C., and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com