Method and equipment for synthesizing lithium tantalite doped potassium sodium niobate ceramic

A technology of potassium sodium niobate and synthesis method, which is applied in the field of functional ceramics, can solve the problems of reducing the activation energy of the reaction and not conforming to environmental protection, and achieves excellent electromechanical performance, good commercial value, and the effect of solving environmental loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

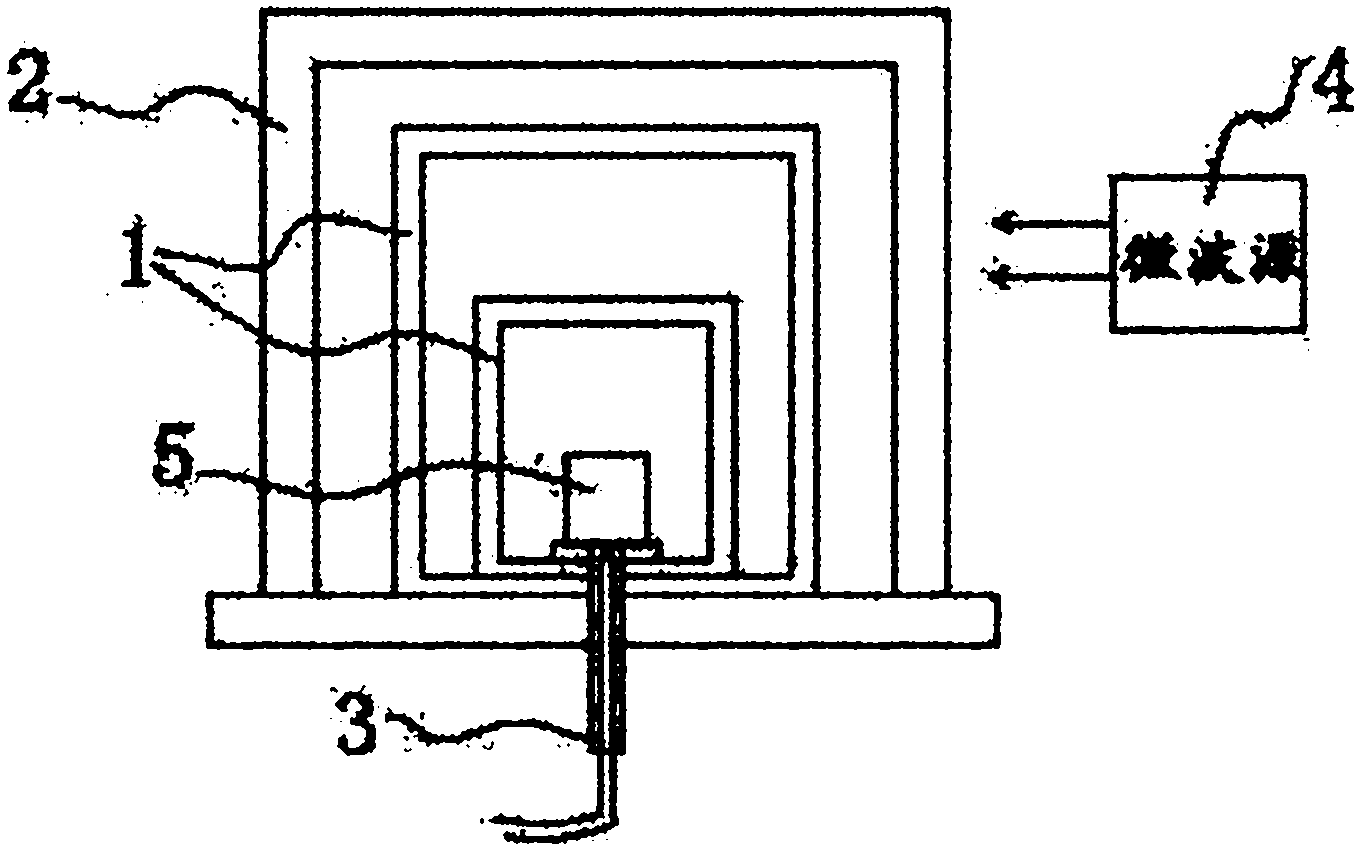

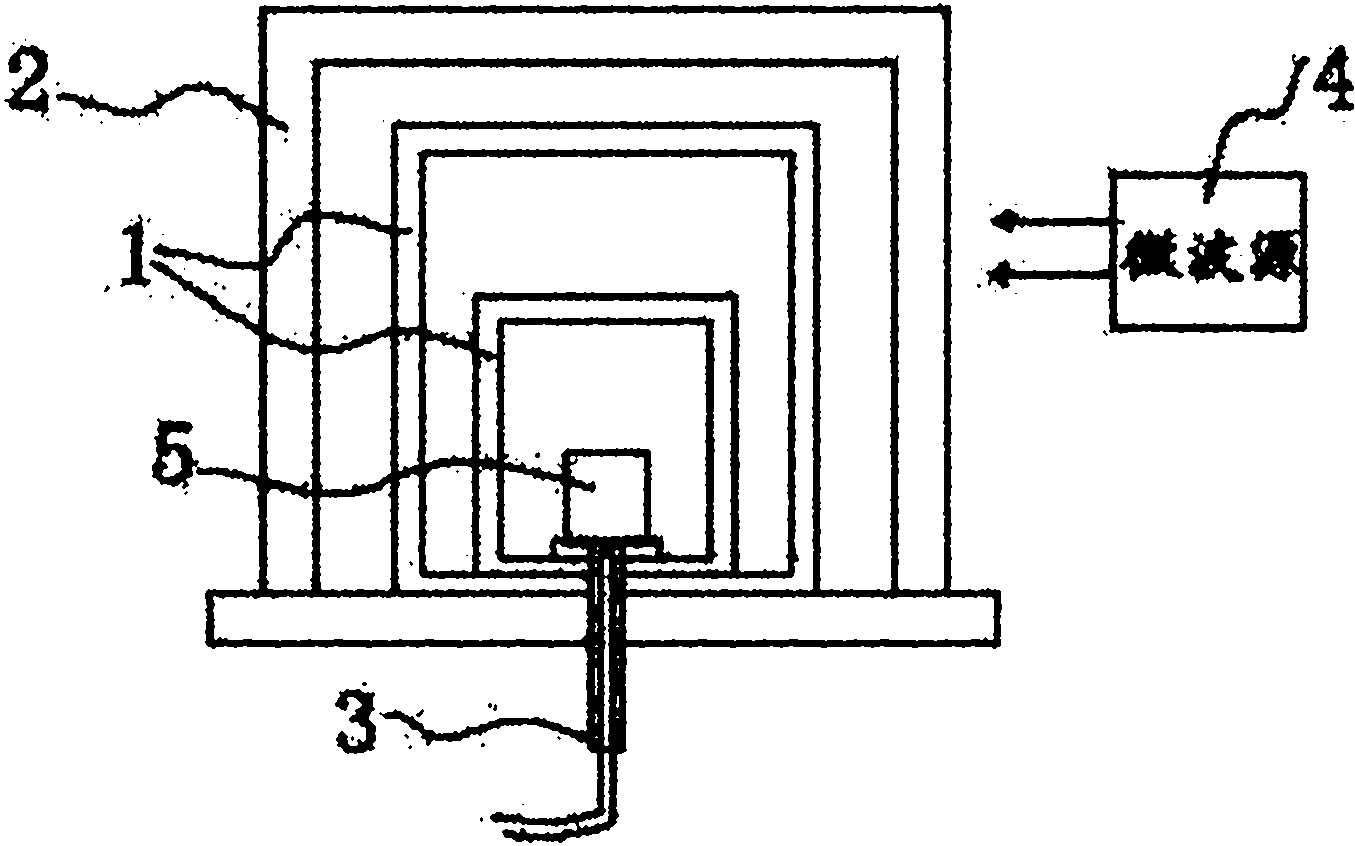

Image

Examples

Embodiment 1

[0024] The compounding ratio (mole percentage) of three components is: 10% of lithium tantalate, 45% of potassium niobate, and 45% of sodium niobate. Ball milling and mixing, adding 5% polyvinyl alcohol (PVA) to granulate, and dry pressing under 200Mpa pressure to make green body. Under the condition of 450°C for 5 hours, the viscous body was debonded, and the debonded sample was loaded into a multi-mode resonant cavity microwave sintering equipment. The first step is rapid heating, the heating rate is 20°C / min, and the temperature is raised to 1100°C for 3 minutes; the second step is rapid cooling, the cooling rate is 40°C / min, down to 950°C, and the heat preservation is 45min.

[0025] The electromechanical performance is: d 33 =255PC / N,k P =0.51,Q m =450,ε 33 T / ε 0 = 808, tan δ = 0.005.

Embodiment 2

[0027] The compounding ratio (mole percentage) of three components is: 10% of lithium tantalate, 45% of potassium niobate, and 45% of sodium niobate. Ball milling and mixing, adding 5% polyvinyl alcohol (PVA) to granulate, and dry pressing under 200Mpa pressure to make green body. Under the condition of 450°C for 5 hours, the viscous body was debonded, and the debonded sample was loaded into a multi-mode resonant cavity microwave sintering equipment. The first step is rapid heating, the heating rate is 20°C / min, and the temperature is raised to 1100°C for 3 minutes; the second step is rapid cooling, the cooling rate is 40°C / min, down to 1000°C, and the heat preservation is 90 minutes.

[0028] The electromechanical properties are: :D 33 =268PC / N,k P =0.52, Q m =380,ε 33 T / ε 0 = 870, tan δ = 0.008.

Embodiment 3

[0030] The compounding ratio (mole percentage) of three components is: 10% of lithium tantalate, 45% of potassium niobate, and 45% of sodium niobate. Ball milling and mixing, adding 5% polyvinyl alcohol (PVA) to granulate, and dry pressing under 200Mpa pressure to make green body. Under the condition of 450°C for 5 hours, the viscous body was debonded, and the debonded sample was loaded into a multi-mode resonant cavity microwave sintering equipment. The first step is rapid heating, the heating rate is 20°C / min, and the temperature is raised to 1150°C for 1 minute; the second step is rapid cooling, the cooling rate is 40°C / min, down to 950°C, and the heat preservation is 90min.

[0031] The electromechanical performance is: d 33 =283PC / N,k P =0.53, Q m =320,ε 33 T / ε 0 = 896, tan δ = 0.011.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com