Method for improving graphitization and carbonizing degree of carbon material based on magnetic field and catalysis

A carbonization degree and carbon material technology, applied in the field of material engineering, can solve problems such as poor controllability, and achieve the effect of improving the degree of graphitization and carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

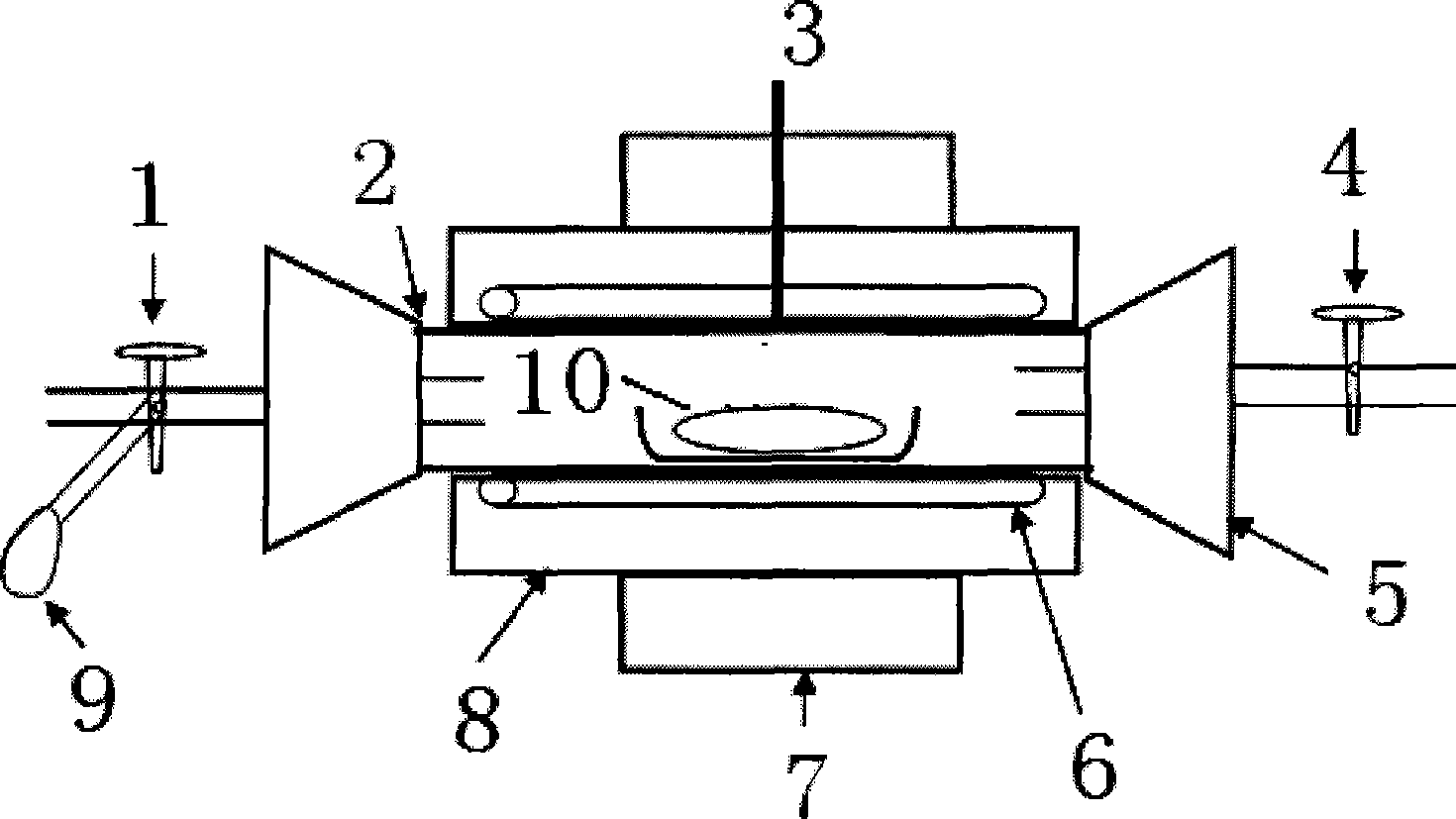

[0027] figure 1 The basic experimental device diagram is given, and the main functions of each component are as follows:

[0028] Ceramic tube 2: hold the sample and create a nitrogen-protected atmosphere for the reaction;

[0029] Condensate 8: reduce the temperature of the furnace wall;

[0030] Three-way valve 1 and two-way valve 4: mainly used to pass nitrogen into the ceramic tube and vacuumize;

[0031] Buffer balloon 9: After vacuuming, appropriate nitrogen gas is retained in it to ensure that the reaction process is carried out under the protection of nitrogen gas;

[0032] Thermocouple 3: Measure the temperature in the furnace and connect with the temperature controller;

[0033] Magnet 7: Provide a stable magnetic field in the sample placement area;

[0034] Silicon carbon rod 6: used for heating, connected to the temperature controller to raise the temperature according to the program under its control;

[0035] Rubber stopper 5: seal the ceramic tube to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com