Lightweight aggregate binder formulation

A lightweight aggregate and clay technology, applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as poor storage effect of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] binder

[0033] distilled water

[0034] Any chemical substance listed in the above formula can be replaced by a compatible chemical substance with similar properties, and the relevant dosage can be adjusted accordingly by a skilled formulator according to the content disclosed in this manual.

Embodiment 2

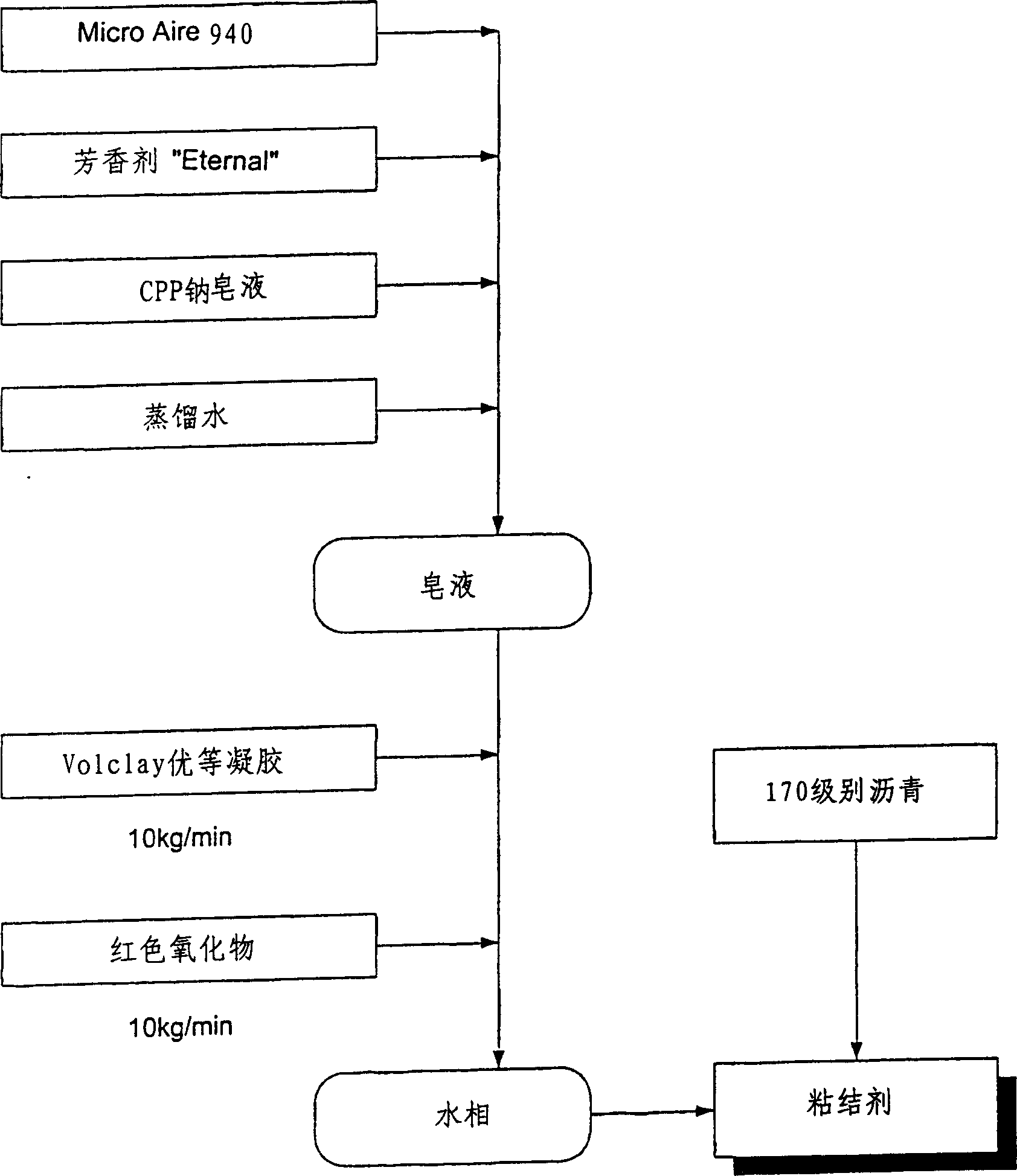

[0036] Binder preparation

[0037] The binder formulations of the present invention are preferably formed by an "in-line" emulsification process according to the following steps:

[0038] 1. Add air-entraining agent "Micro-Arie 940", desired fragrance "Eternal" and antimicrobial agent sodium o-phenylphenate ("opp") to distilled water to make a soap solution. The soap was circulated for 25 minutes while warming to 35°C.

[0039] 2. Then, add Volclay(R) fine gel into the soap solution at a slow rate of about 10 kg / min.

[0040] 3. Next, disperse the red oxide into the mixture at a rate of about 10 kg / min.

[0041] 4. The mixture was sheared in a high shear mill while adding 170 grade bitumen at 195°C at a rate of about 1500 kg / hr.

[0042] In the above method, the exact order of addition when preparing the composition is extremely important in obtaining the water-in-oil emulsion structure and providing useful properties to the coating composition. Those skilled in the art wi...

Embodiment 3

[0044] Physical Structure of Emulsion

[0045] The preferred physical structures of the preferred natural anionic oxides in the present invention can be classified as "acicular" or "spherical". "Acicular" oxides retain more water and, when made into pastes, are drier and therefore more viscous than the corresponding "spherical" oxides. Acicular oxides are preferred, but the oxides can be "acicular" or "spherical".

[0046] In the present invention, the droplet diameter of the emulsion is about 25 microns, which is much larger than the droplet diameter (about 5 microns) in a typical emulsion; meanwhile, the emulsion droplets contain suspended oxides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com