Ceramic particles, and processing system and processing method thereof

A technology of ceramic particles and processing system, which is applied in the direction of extrusion and granulation of raw materials, and can solve the problem of inability to process ceramic particles quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

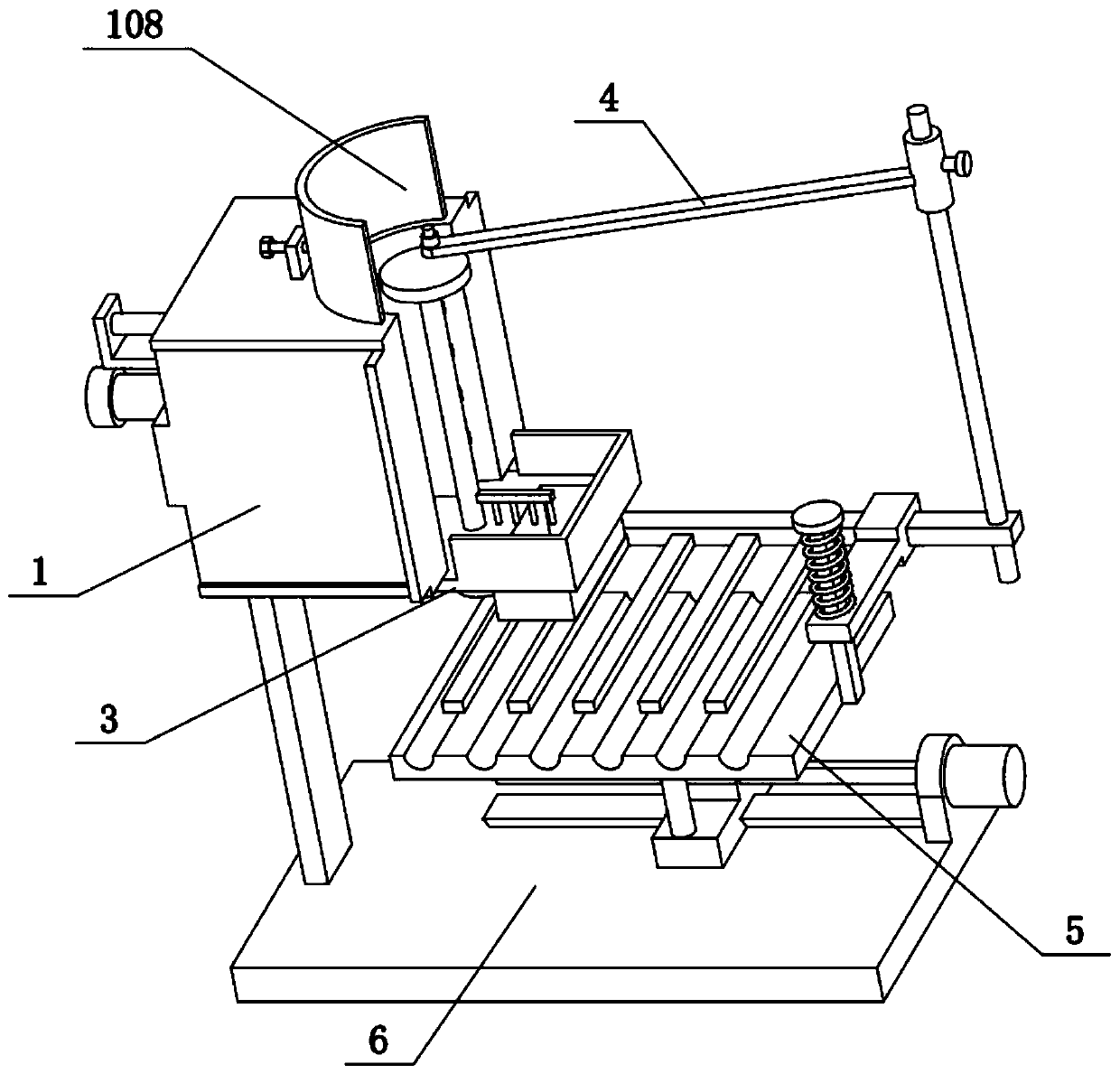

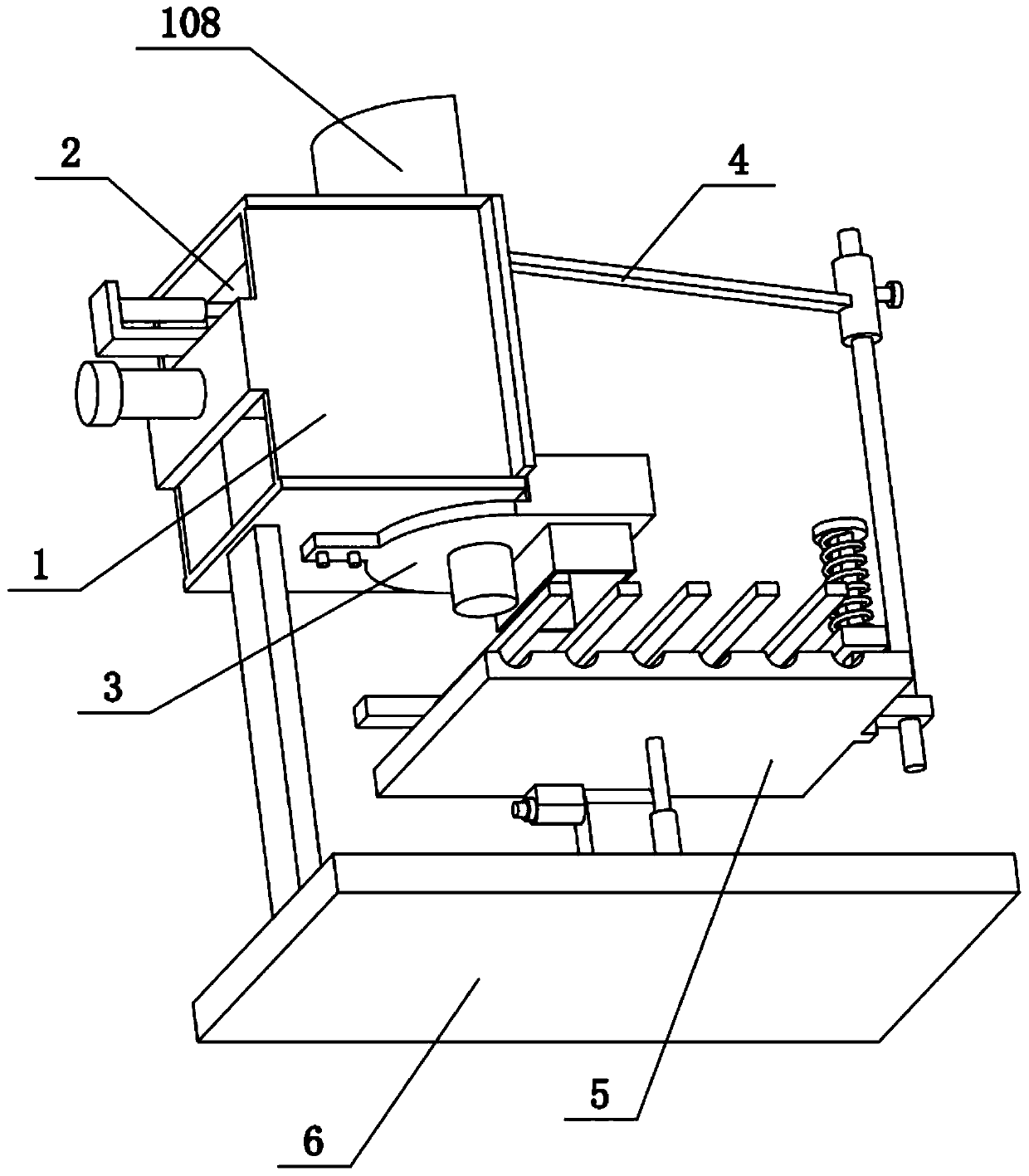

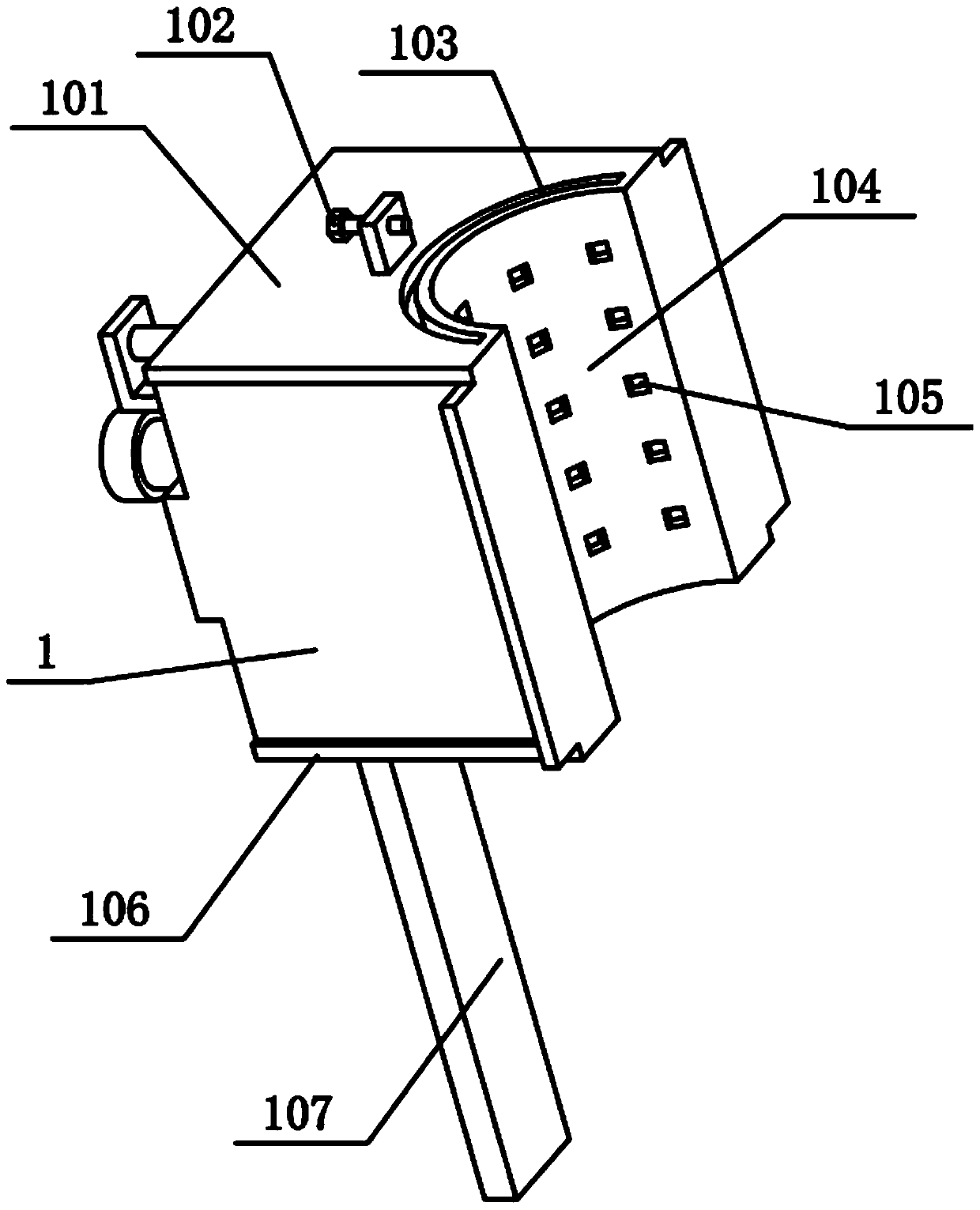

[0033] Combine below Figure 1-8 This embodiment is described. The present invention relates to the field of ceramic particle processing, more specifically, a ceramic particle and its processing system and processing method, including a storage box 1, a top cover 101, an arc-shaped depression 104, an extrusion hole 105, Bottom cover 106, push block 2, tray 3, motor 301, scraper 302 and vertical shaft 303, the present invention can scrape off raw materials after being extruded through holes, and quickly process ceramic particles.

[0034]The upper and lower sides of the storage box 1 are respectively provided with a top cover 101 and a bottom cover 106, and the right side of the storage box 1 is provided with an arc-shaped depression 104, and a plurality of extrusion holes 105 are arranged on the arc-shaped depression 104. Each extrusion hole 105 is connected with the storage box 1, the left side of the storage box 1 is open, the left part of the storage box 1 is slidingly conn...

specific Embodiment approach 2

[0036] Combine below Figure 1-8 To illustrate this embodiment, the ceramic particle processing system also includes a fastening screw I102, an arc-shaped cover groove 103 and an arc-shaped cover 108. Cover groove 103, arc-shaped cover 108 is slidably connected with the arc-shaped cover groove 103, when the arc-shaped cover 108 is inserted into the material storage box 1, a plurality of extrusion holes 105 can be blocked, and the fastening screw I102 is supported on the arc-shaped cover 108 The arc cover 108 is secured. The arc-shaped cover 108 can slide vertically on the arc-shaped cover groove 103, thereby controlling the opening and closing of a plurality of extrusion holes 105, and the position of the arc-shaped cover 108 can be fixed by turning the fastening screw I102.

specific Embodiment approach 3

[0038] Combine below Figure 1-8 Illustrate the present embodiment, described ceramic grain processing system also comprises side plate 201, electric telescopic rod 1202, dome 203 and feeding pipe 204, the left side of storage box 1 is fixedly connected with side plate 201, the electric telescopic rod 1202 One end is fixedly connected to the side plate 201, and the other end of the electric telescopic rod 1202 is fixedly connected to the push block 2. The left side of the push block 2 is provided with a feed pipe 204, and the feed pipe 204 is slidably connected to the side plate 201. The left end of the feed pipe 204 is threadedly connected with a round cover 203 , and the feed pipe 204 communicates with the inside of the storage box 1 . After the round cover 203 is opened, the kaolinite clay can be passed into the storage box 1 from the feed pipe 204 to feed the storage box 1. When the electric telescopic rod I202 is extended or shortened, it can drive the push block 2 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com