Flax ultrashort fiber geopolymer composite ornamental molding material

A geopolymer and art modeling technology, which is applied in the field of preparation of flax very short fiber geopolymer composite art modeling materials, can solve the problems of monotonous variety of modeling materials, poor comprehensive use effect, and low resource utilization rate, etc. Practical significance, good hardness, good expressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

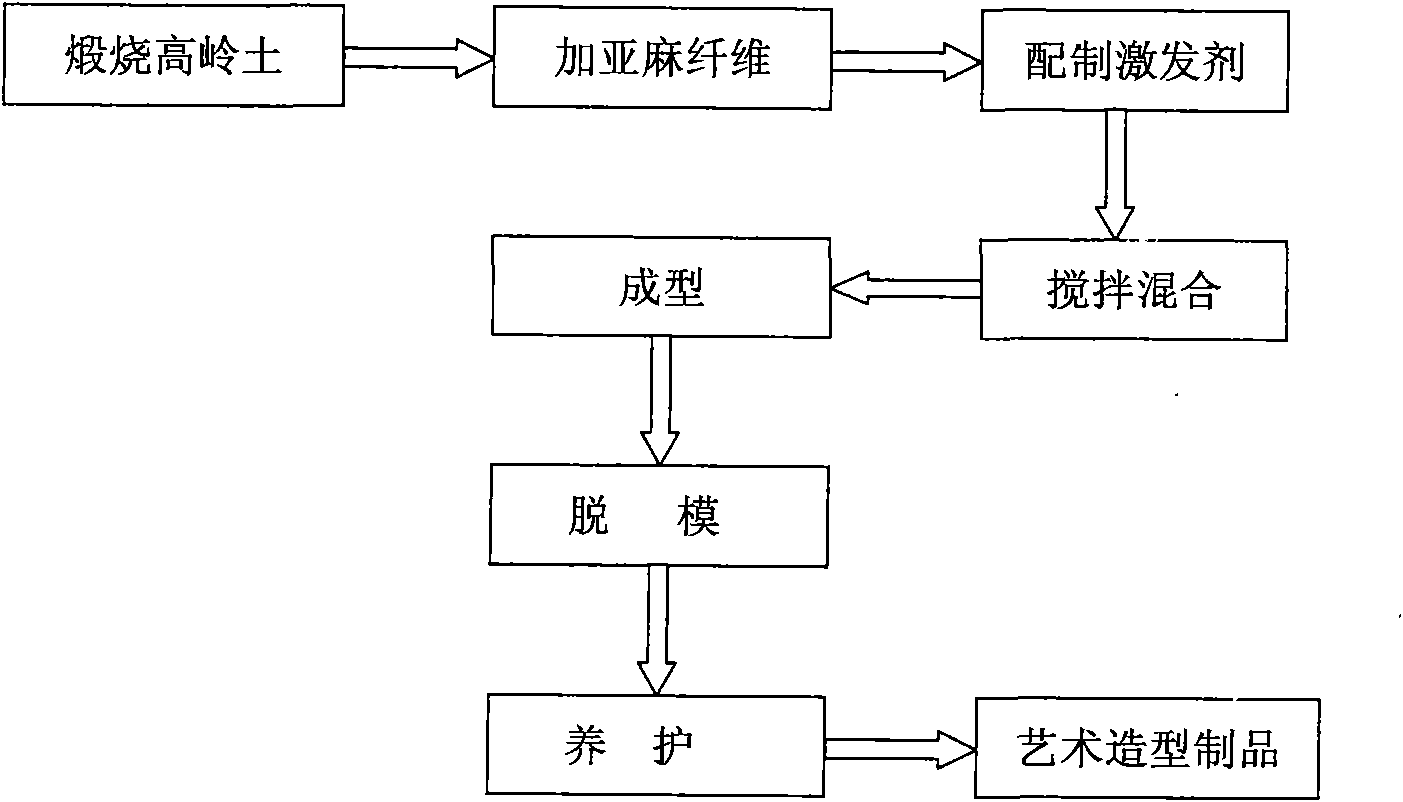

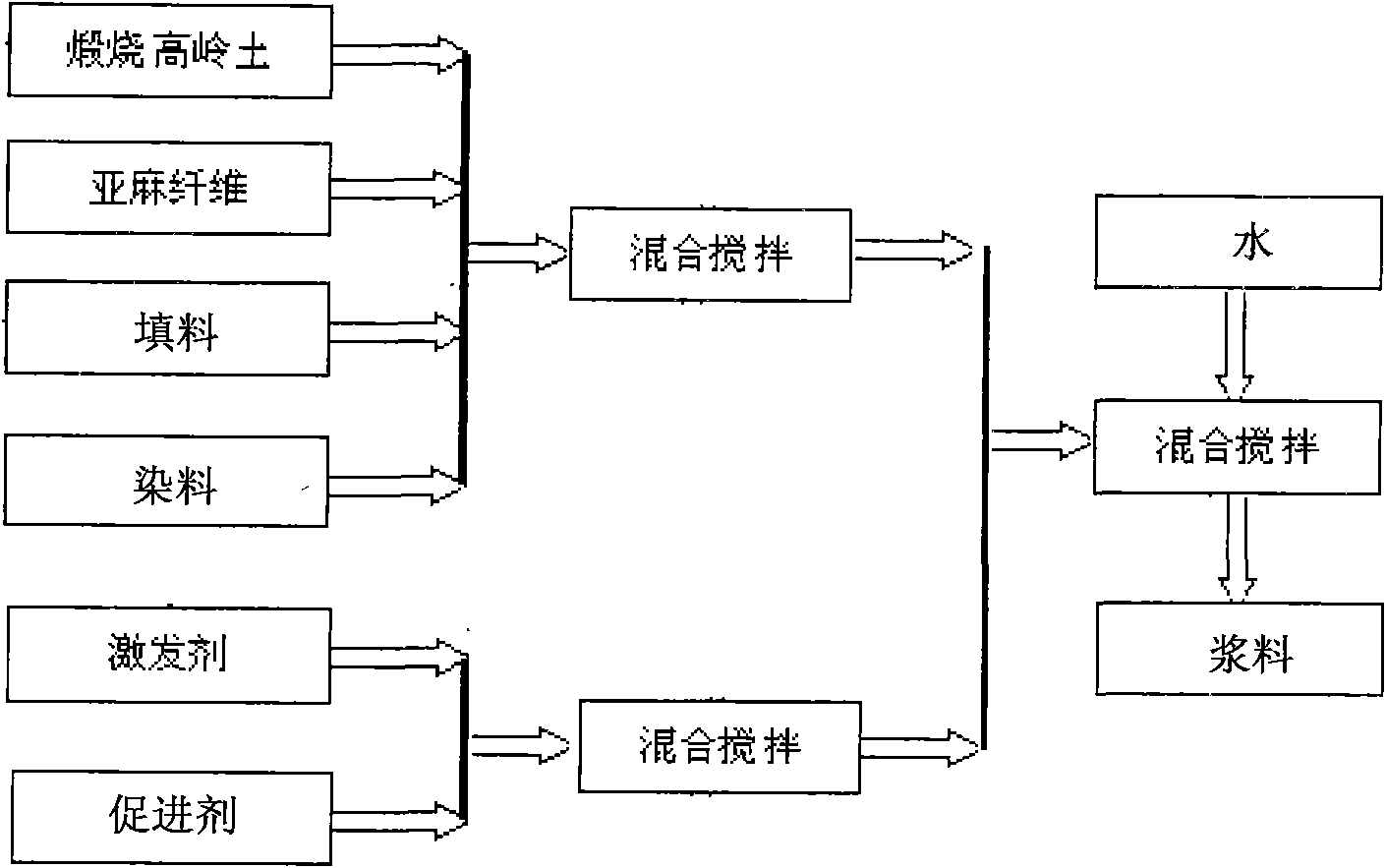

Method used

Image

Examples

Embodiment 1

[0028] Blend 5% flax short fiber with 70% calcined kaolin and 10% calcium carbide slag, after mixing evenly, add 10% hardener and 5% accelerator, add 5-20% water to the above materials, mix and stir After 2 minutes, a composite slurry was obtained. The composite modeling material is ivory white, shiny and hard after curing.

Embodiment 2

[0030] Blend 40% flax short fiber with 40% calcined kaolin and 10% calcium carbide slag by weight. After mixing evenly, add 5% hardener, 4% accelerator and 1% dye, add water to the above materials for 5-20 %, mixed and stirred for 2 minutes to obtain a composite slurry. After being cured, the composite molding material is dye-colored, sub-glossy, flexible and processable.

Embodiment 3

[0032] Blend 20% flax short fiber by weight with 50% calcined kaolin and 15% fly ash, and after mixing evenly, add 10% hardener, 4.5% accelerator and 0.5% dye, and add water to the above materials for 5~ 20%, mixed and stirred for 2 minutes to obtain a composite slurry. The composite molding material is light dye-colored after solidification, dull and hard in texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com