Cristobalite high strength porcelain formula

A high-strength, quartz-based technology, applied in applications, household appliances, clay products, etc., can solve the problems that high-voltage electric porcelain cannot meet market demand, and achieve the effects of reducing the amount of alumite, reducing production costs, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

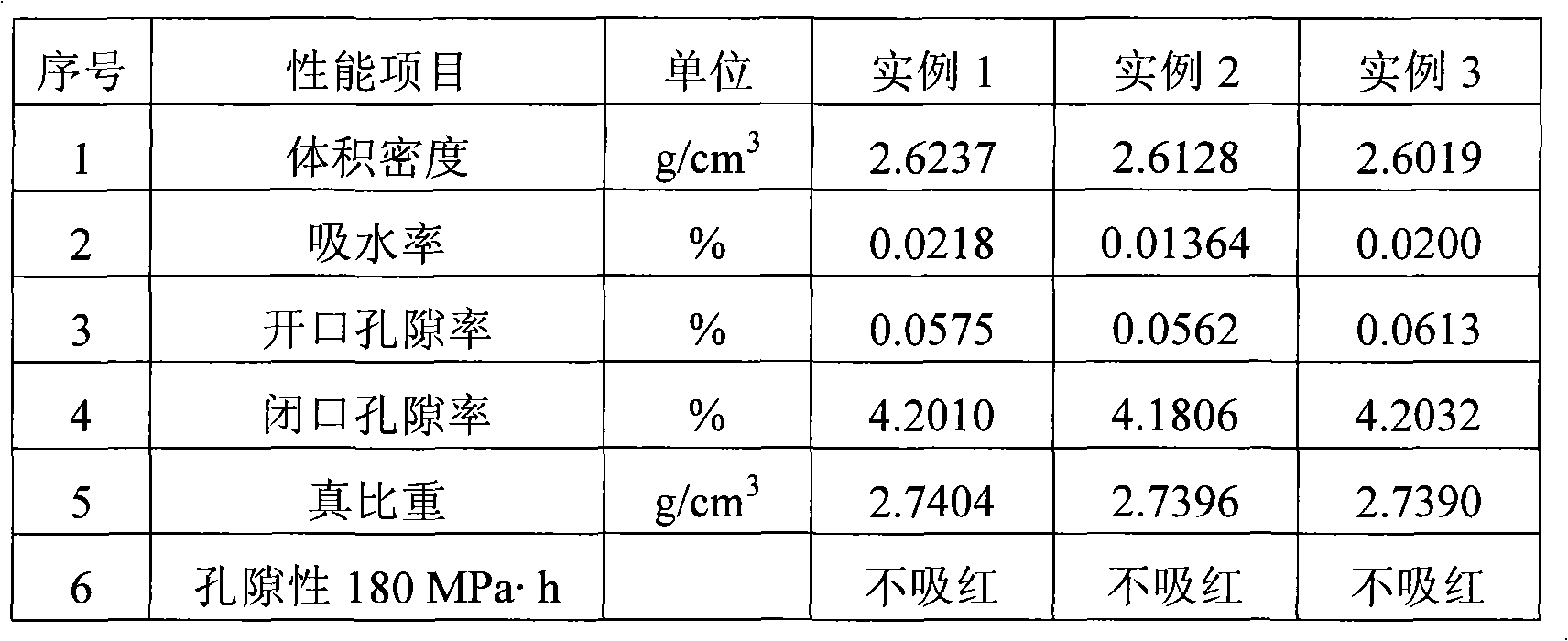

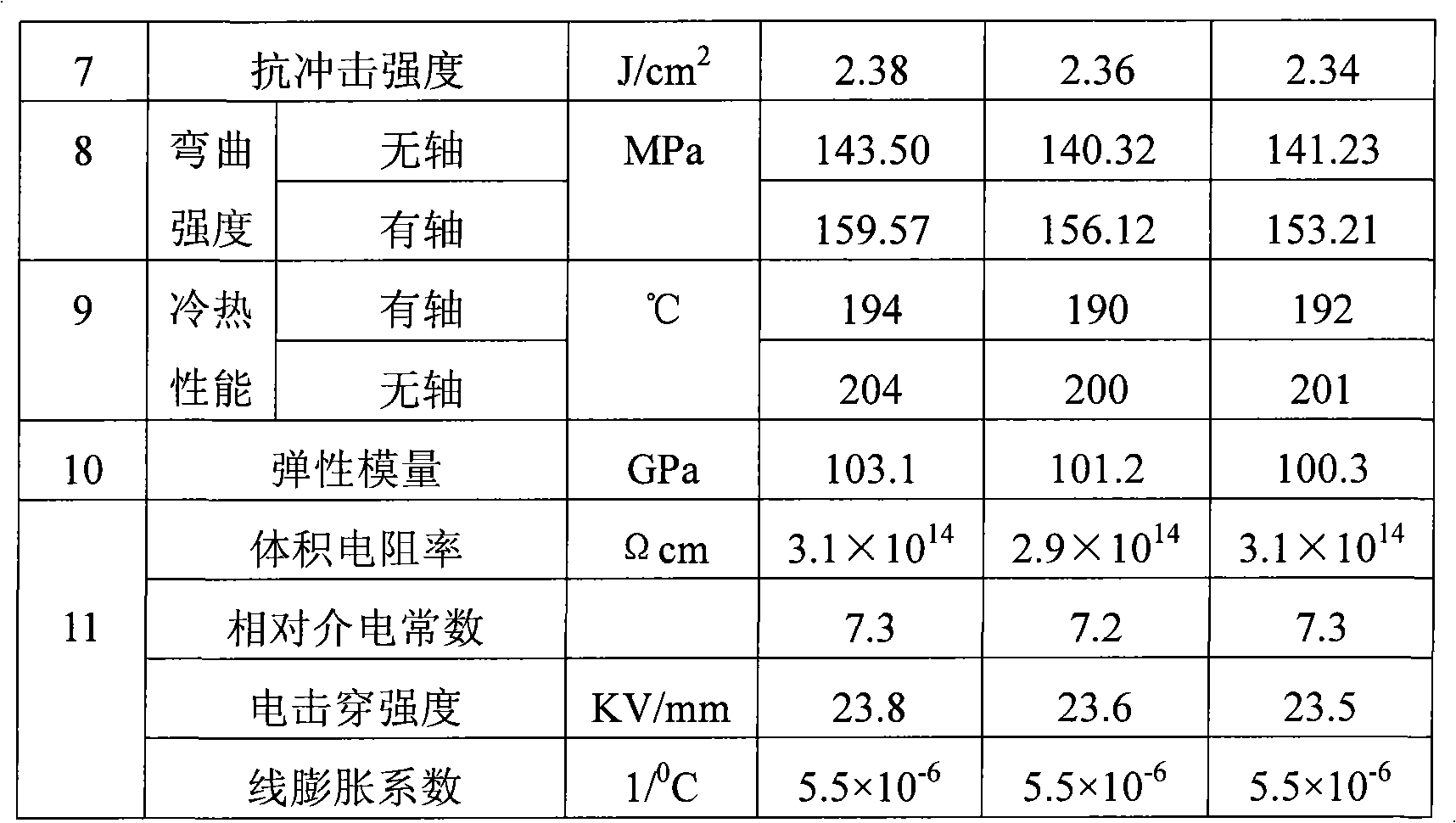

Examples

example 1

[0012] Example 1. Alumite is 24.5, feldspar is 7, Mandshurica mandshurica is 14.5, Tianshifu is 22.5, white dry stone is 11, and Faku is 20.5.

example 2

[0013] Example 2. Alumite is 26, feldspar is 7, Mandshurica mandshurica is 17, Tianshifu is 19, white dry stone is 10, and Faku is 21.

example 3

[0014] Example 3, alumite is 22.5, feldspar is 8, Mandshurica mandshurica is 14, Tianshifu is 23, white dry stone is 10, and Faku is 22.5.

[0015] The chemical analysis of above-mentioned proportioning example is as follows: (%)

[0016]

SiO 2

al 2 o 3

Fe 2 o 3

CaO

MgO

K 2 O+Na 2 o

TiO 2

I.L.

Example 1

49.89

38.58

1.01

0.46

0.40

2.60

1.59

5.75

Example 2

48.68

39.26

1.06

0.50

0.50

2.66

1.59

5.74

Example 3

49.56

38.01

0.93

0.39

0.42

2.61

1.46

6.17

[0017] 2. Ball milling

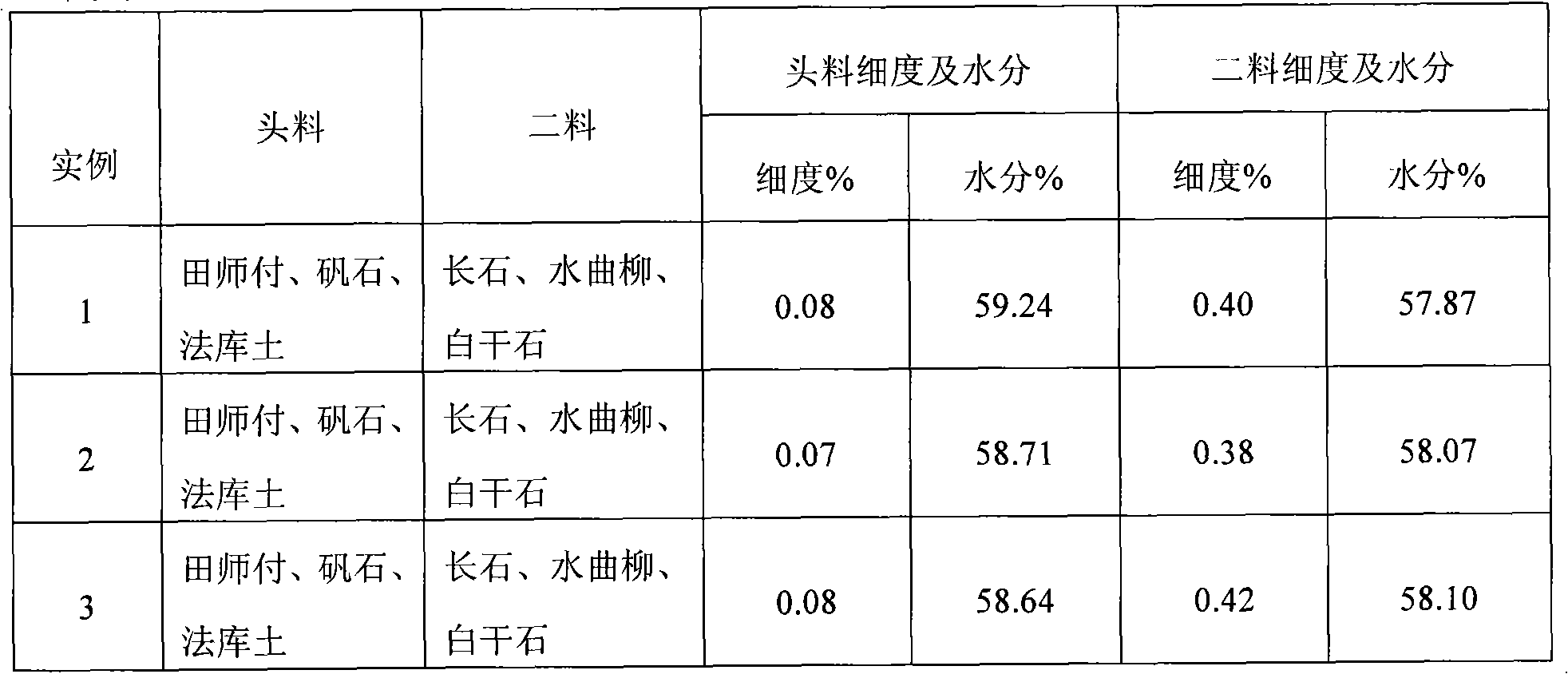

[0018] The type, moisture and fineness of the head material and the second material

[0019] Control standard:

[0020] Ball mill head material Fineness over 320 mesh sieve 0.06~0.1% sieve residue

[0021] The second material of ball mill, the fineness is over 300 mesh sieve, and the sieve residue is 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com