Authigenic medium vibrated fluidized bed dry separating method and separating machine

A technology of medium vibration and fluidized bed, which is applied in chemical instruments and methods, separating solids from solids with airflow, solid separation, etc., to achieve the effects of reducing sorting load, low sorting cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

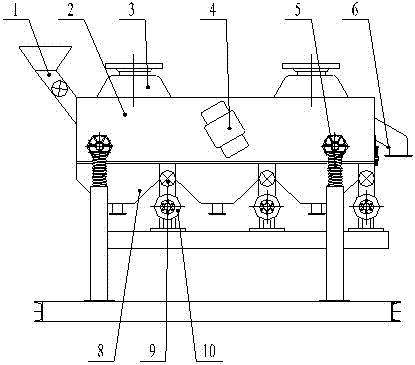

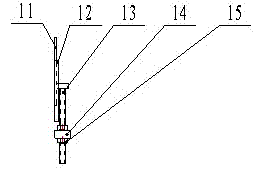

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

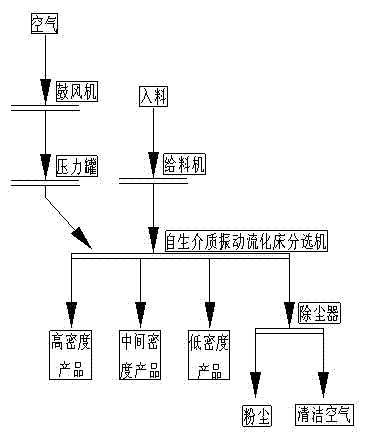

[0021] Such as figure 1 As shown, the self-generating medium vibrating fluidized bed dry sorting method of the present invention: feed the material into the self-generating medium vibrating fluidized bed sorting machine with three sorting sections through the feeder 1, and start the vibration excitation motor 4; Air is supplied to the three air distribution chambers 8 respectively, and the air enters through the blower, then enters through the pressure tank, and evenly enters the sorting bed 2 of the three sorting sections through the gas distributor and air distribution plate installed in the three air distribution chambers 8 Inside, the sorting bed 2 of the three sorting sections moves linearly under the action of the exciting force provided by the exciting motor 4, and the materials are fluidized under the synergistic effect of the updraft and the excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com