Vibratory fluidized bed reactor for continuous production of rare earth fluorides and production method

A fluidized bed reactor, rare earth fluoride technology, applied in chemical instruments and methods, rare earth metal compounds, inorganic chemistry, etc., can solve the problem of difficulty in ensuring uniformity of rare earth fluoride, low production process efficiency, large gas diffusion resistance, etc. problems, to achieve the effect of optimizing the gas-solid fluidization reaction process, improving production efficiency and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

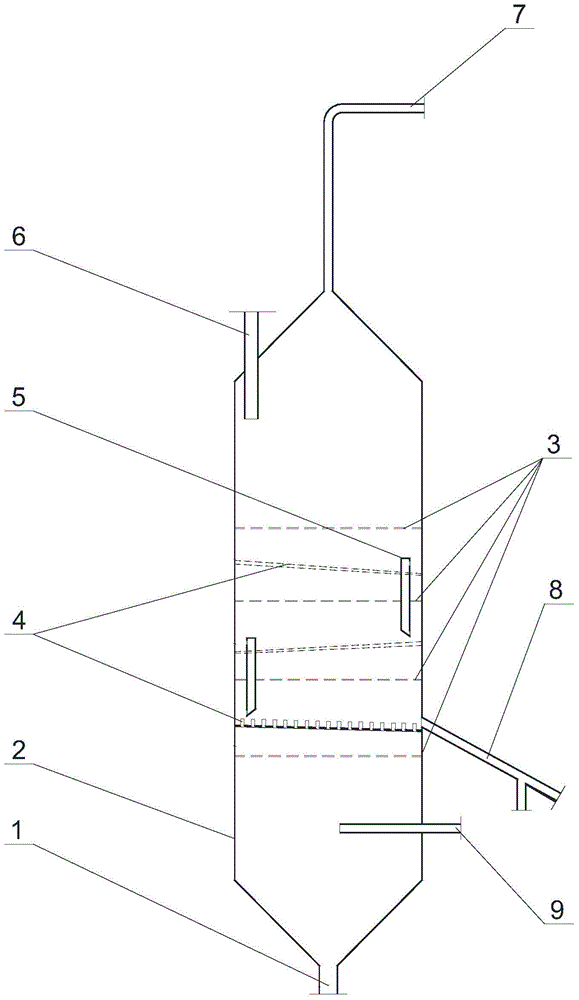

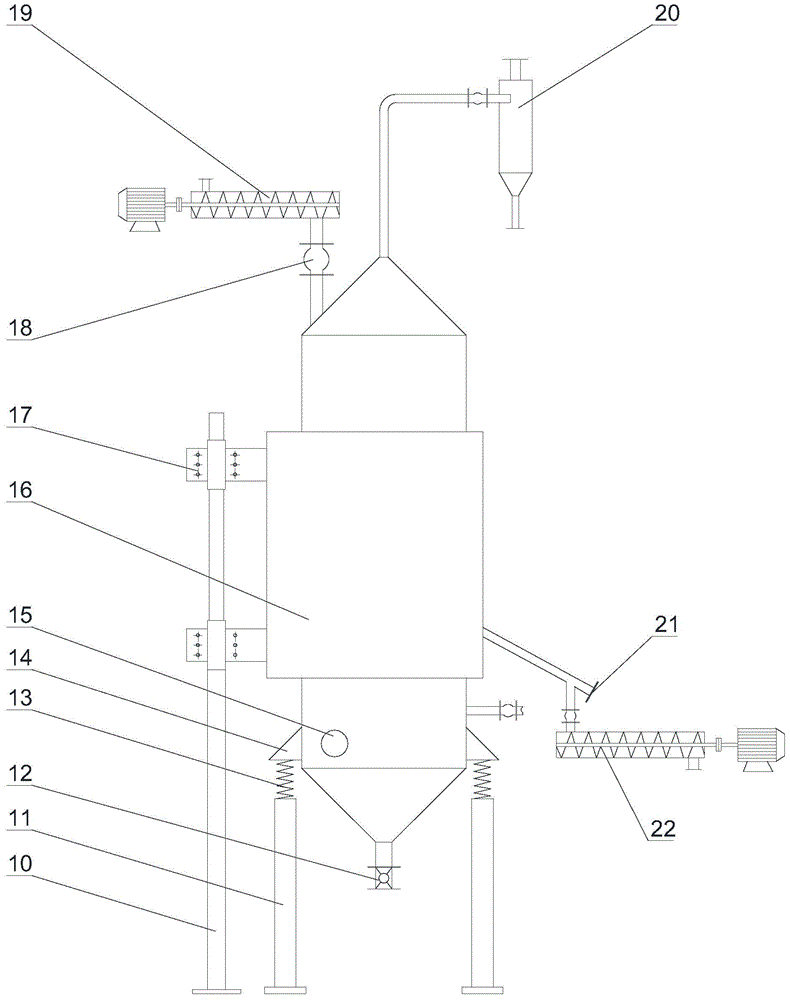

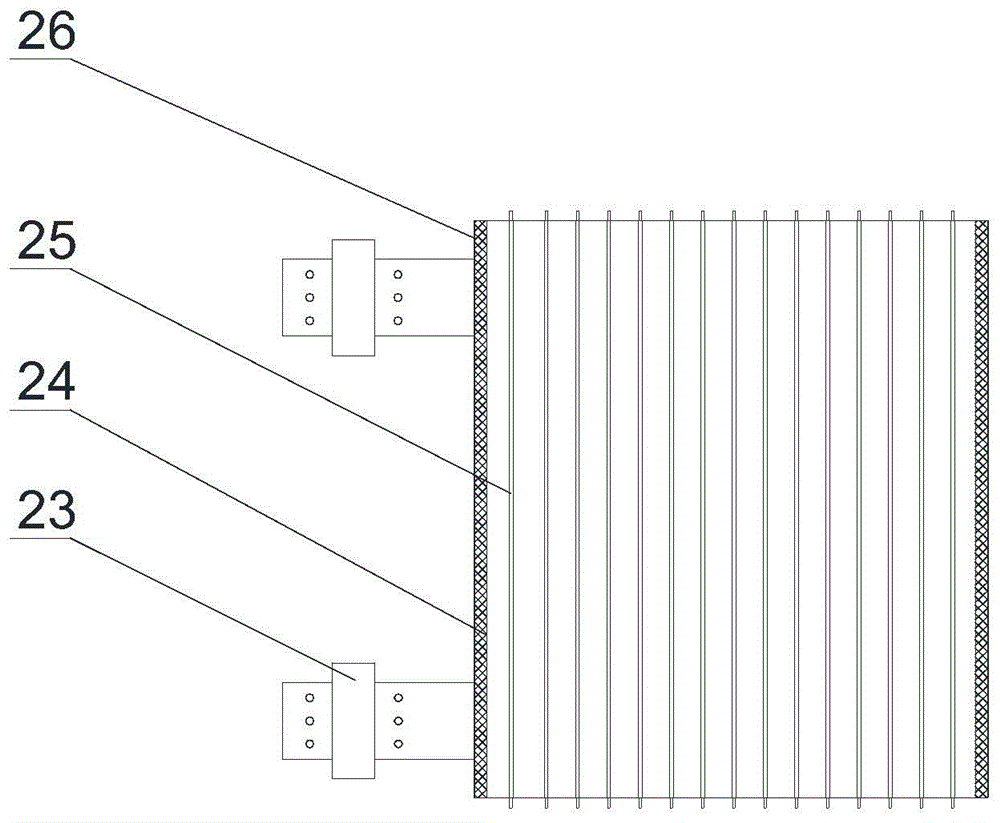

[0045] A vibrating fluidized bed reactor for continuous production of fluorinated rare earths according to the present invention, its main structure and connection mode are the same as those of the vibrating fluidized bed reactor described in the above specific embodiments, including the feeding device 19 , discharge device 22, fluidized bed, vibrator 15 and heating device; Fluidized bed comprises approximately cylindrical fluidized bed body 2, and the top of fluidized bed body 2 is a cone shape, and the bottom is an inverted cone Tubular shape, the middle body is cylindrical. The top of the fluidized bed body 2 is provided with a rare earth-containing material feed port 6 connected with the feed device 19; the middle and lower part of the fluidized bed body 2 is provided with a fluoride rare earth product discharge port 8 connected with the discharge device 22 . The bottom of the fluidized bed body 2 is also provided with a gas inlet 9 containing hydrogen fluoride. The cavit...

Embodiment 2

[0061] A vibrating fluidized bed reactor for continuous production of rare earth fluorides according to the present invention, its main structure and connection mode are the same as those of the vibrating fluidized bed reactor described in Example 1 above, the only difference is: The gas distribution plate 4 in this embodiment has four layers, and the opening ratio of each gas distribution plate is 1% to 6%.

[0062] The method for continuously producing cerium fluoride using the vibrating fluidized bed reactor of this embodiment may further comprise the steps:

[0063] (1) Start the heating device to heat the cavity of the uppermost gas distribution plate 4 set in the fluidized bed body 2 to 250°C;

[0064] (2) Evenly add rare earth-containing material cerium carbonate particles into the vibrating fluidized bed reactor through the feed device 19, and the cerium carbonate particles enter the cavity of the fluidized bed body 2 through the rare earth-containing material feed por...

Embodiment 3

[0070] A vibrating fluidized bed reactor for continuous production of rare earth fluorides according to the present invention, its main structure and connection mode are the same as those of the vibrating fluidized bed reactor described in Example 1 above, the only difference is: In this embodiment, the opening ratio of each gas distribution plate is 2.5% to 12.5%; the discharge port 8 of the rare earth fluoride product is externally connected to the discharge pipe, and the center line of the discharge pipe is 60 to the cylinder wall of the fluidized bed body 2. ° included angle, the vibrator is an air turbine vibrator.

[0071] The method for continuously producing neodymium fluoride using the vibrating fluidized bed reactor of this embodiment comprises the following steps:

[0072] (1) Start the heating device to heat the cavity of the uppermost gas distribution plate 4 set in the fluidized bed body 2 to 250°C;

[0073] (2) Evenly add rare earth-containing material neodymiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com