Fluidized bed reactor for producing trichlorosilane

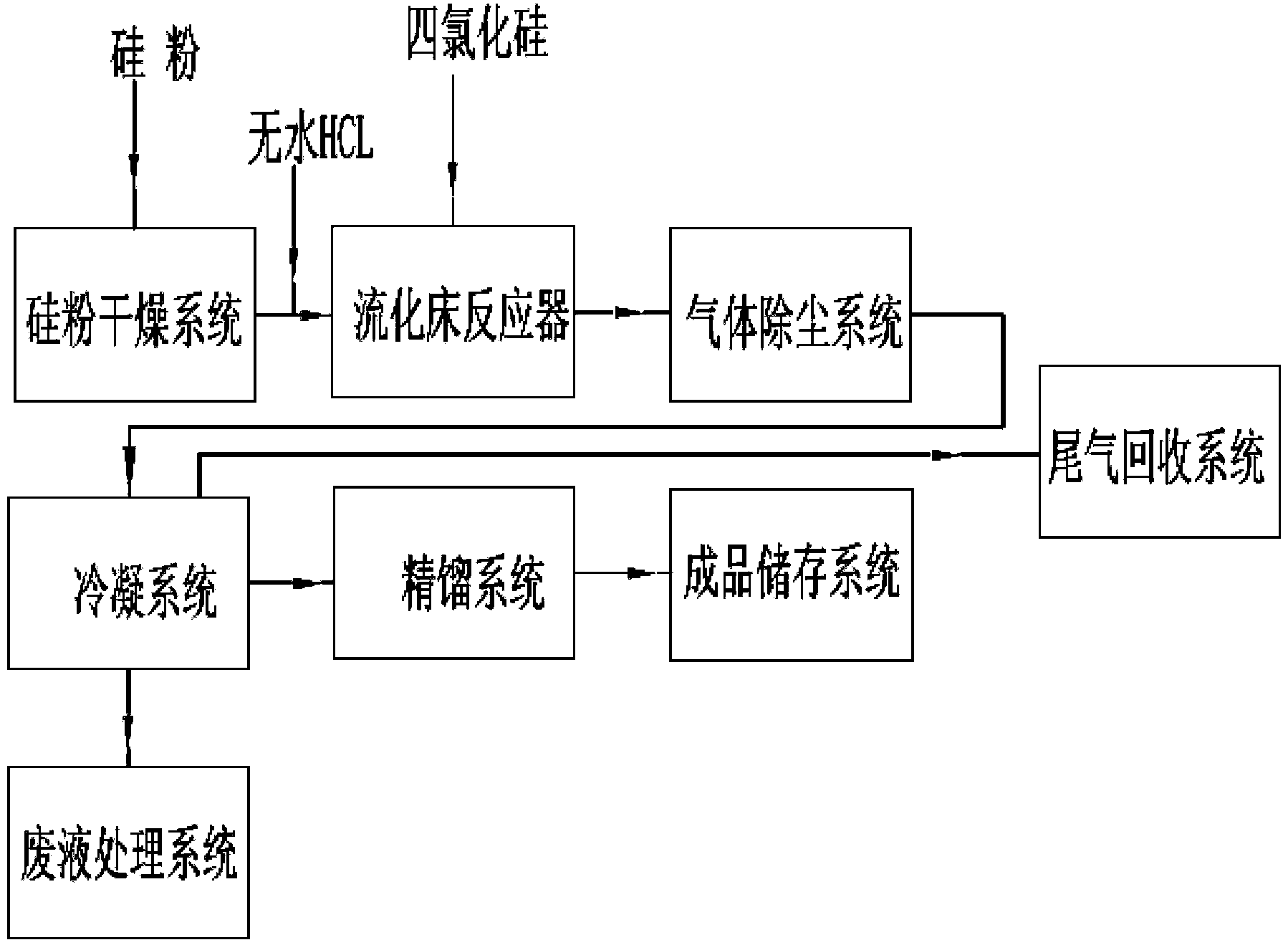

A fluidized bed reactor, trichlorosilane technology, applied in the directions of halogenated silicon compounds, halogenated silanes, etc., can solve the problem of low production capacity of the fluidized bed reactor, unstable trichlorosilane yield, and inconsistent reaction temperature. Easy to control and other problems, to achieve the effects of suppressing the generation of by-product silicon tetrachloride, simple and reliable temperature control operation, reducing energy consumption and fixed investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

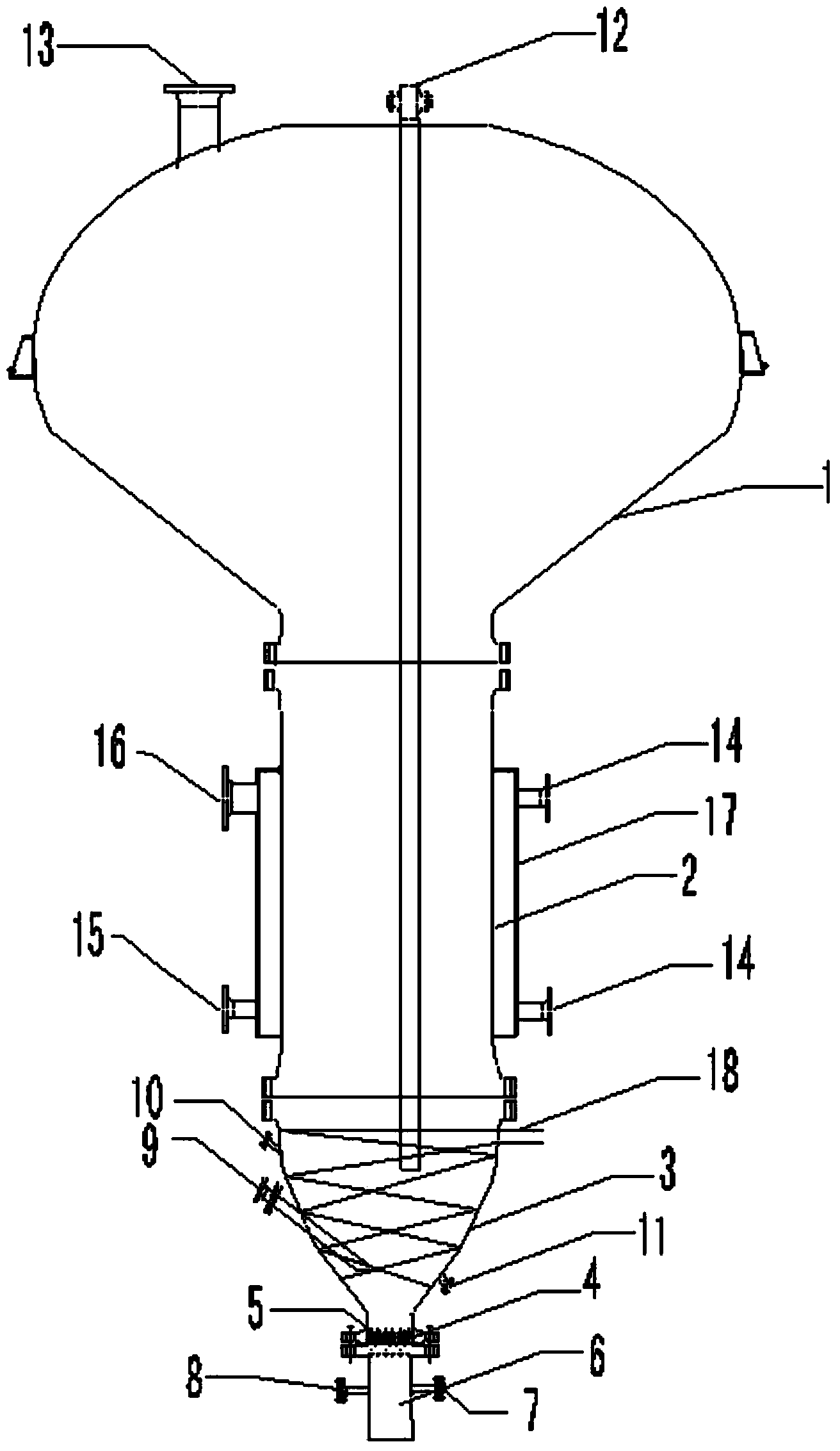

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0032] refer to figure 1 , a fluidized bed reactor for producing trichlorosilane, comprising:

[0033] A reactor body, the reactor body includes a gas distribution section 6 at the lower part, a reaction section 2 at the middle, and an expansion section 1 at the upper part, the gas distribution section 6 and the reaction section 2 are connected by a The inspection head 3 is fixedly connected; the gas distribution section 6, the inspection head 3, the reaction section 2 and the expansion section 1 are connected to each other;

[0034] The gas distribution section 6 includes a gas inlet pipeline, a gas distributor 4 arranged in the gas inlet pipeline, and the gas distributor 4 is used to evenly distribute the bottom hydrogen chloride and silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com