Fluidized bed gasification reaction method and reactor employing packed fuel

A fluidized bed gasification and reactor technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. Problems such as difficulty in material milling, to avoid the problem of easy slagging, easy fluidization of true density, and improvement of fluidization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

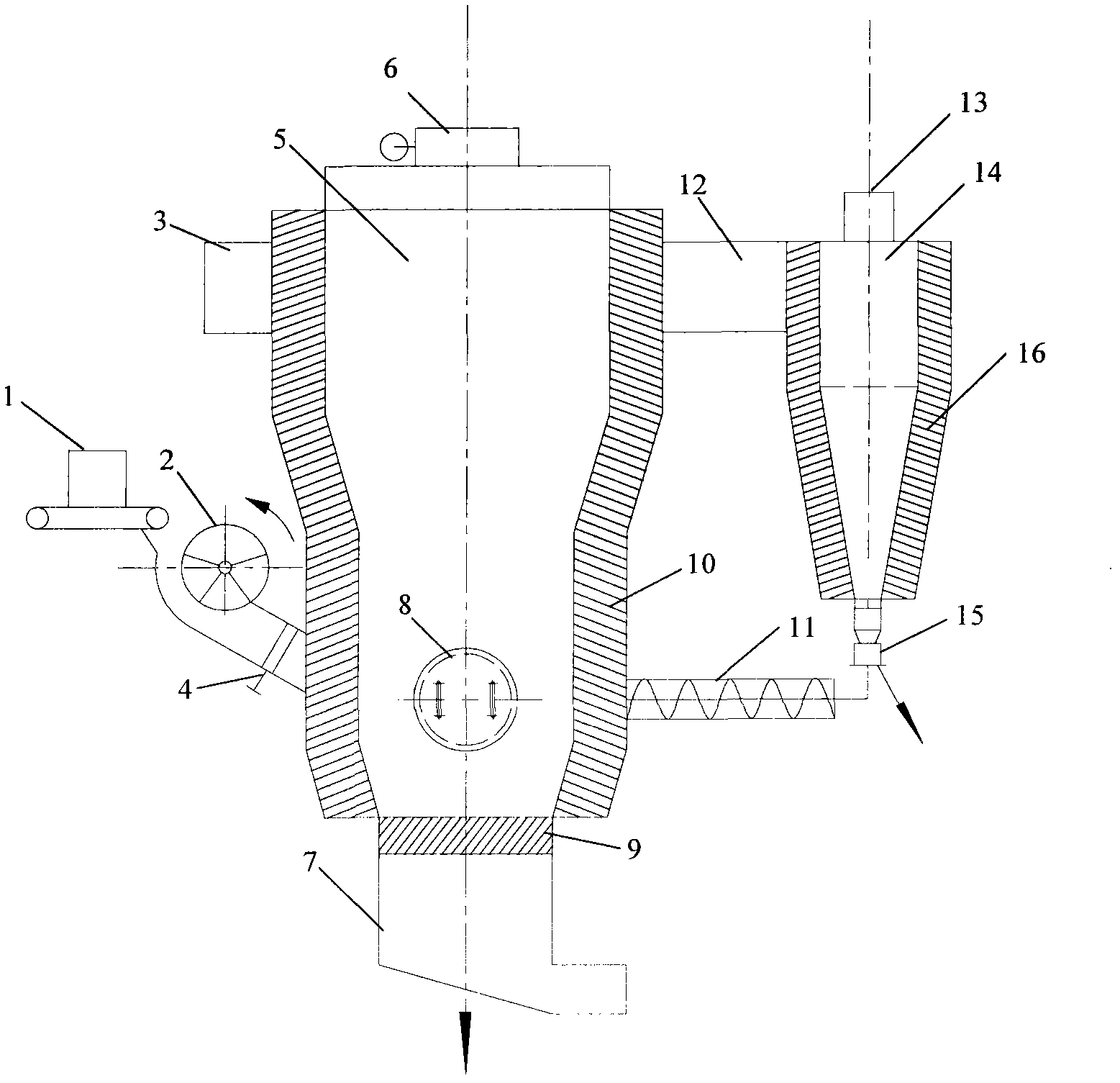

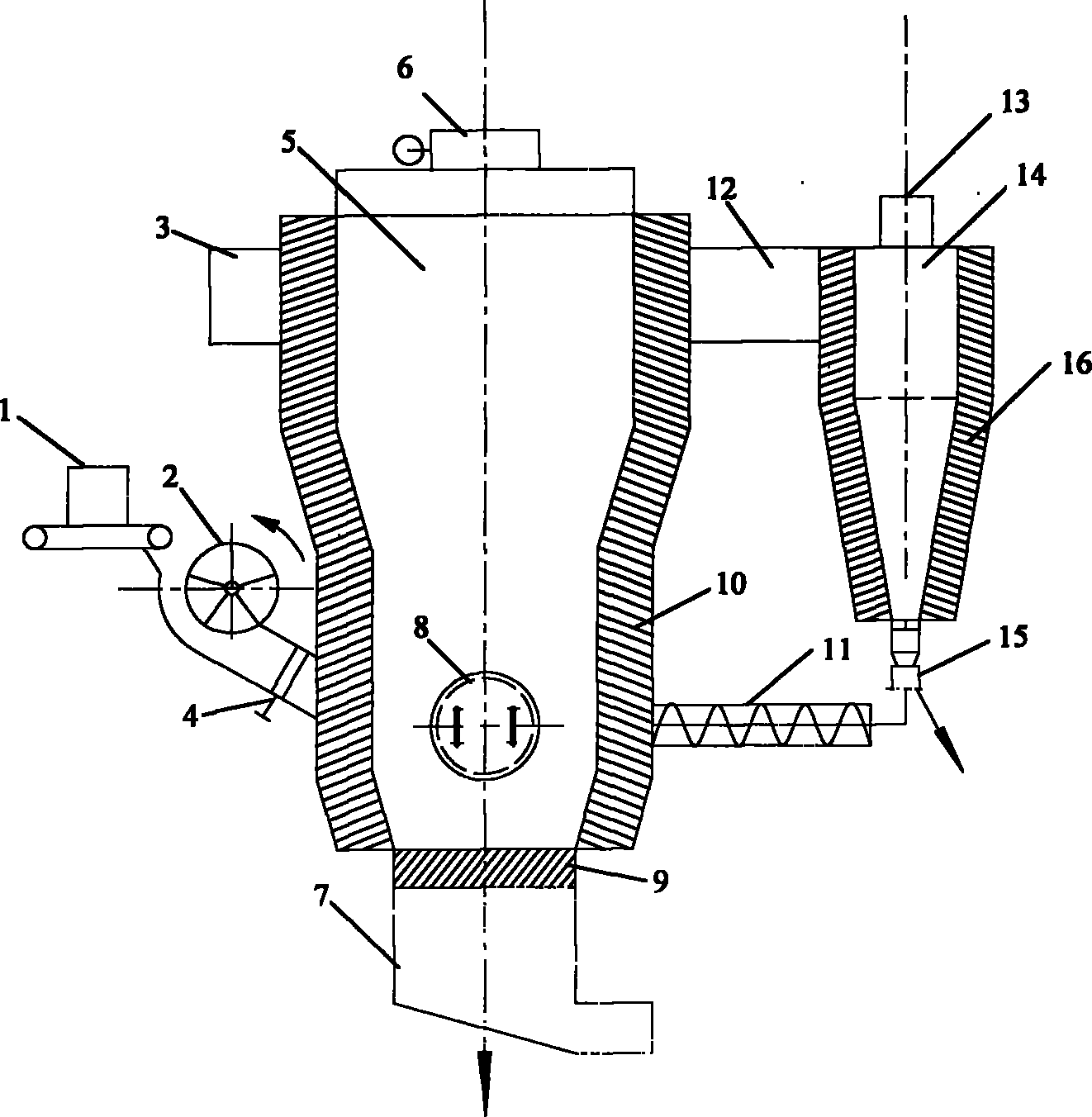

[0031] The present invention provides a fluidized bed gasification reaction method and reactor using packaged fuel. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0032] Such as figure 1 As shown, the top of the gasification chamber 5 is an explosion-proof door 6, the bottom is provided with an air distribution plate 9 and an equal-pressure air chamber 7, the upper part of the side wall of the gasification chamber 5 is provided with a safety door 3 and the outlet 12 of the gasification chamber, and the lower part of the side wall is provided with a shut-off valve. Door 4, manhole door 8 and fly ash heat auger 11; the other end of the gasification chamber outlet 12 is connected to the cyclone separator 14; the top of the cyclone separator 14 is the separator gas outlet 13, and the bottom of the cyclone separator The two-stage slag locker 15 is connected to the fly ash heat auger 11; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com