Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

A technology of fluidized bed reaction and fluidized bed reactor, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems of low fluidization quality, low gas-solid contact efficiency in fluidized bed, bubble Oversize and other problems, to achieve the effect of improved fluidization quality, good gas-solid contact effect, and increased retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

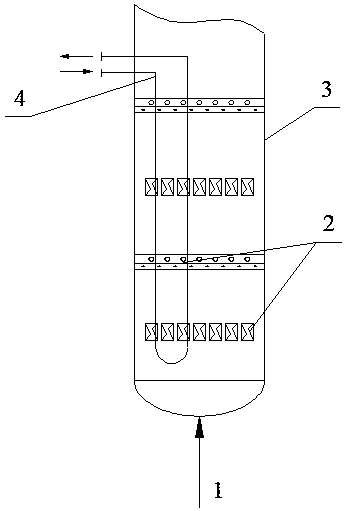

[0029] Such as figure 1 The device for producing aniline by hydrogenation of nitrobenzene is shown. The average particle size of the catalyst is 360 mu m, the largest angle α in the triangular longitudinal section of the left baffle and the right baffle is 135°. The sides of the prism where the longer side of the triangular longitudinal section of the left baffle and the right baffle of the composite member are located are parallel to each other and placed vertically. The sides of the left baffle and the right baffle of the composite component have holes and (or) slits respectively, and the ratio of the total area of the holes and (or) slits to the area of the blades is 15%. Four composite components are set in the fluidized bed reactor, and the composite components are staggered and evenly distributed in the reactor, and the acute angle / right angle between two adjacent composite components in the vertical direction is 90°, and the vertical direction The vertical dista...

Embodiment 2

[0033] Such as figure 1 The device for producing aniline by hydrogenation of nitrobenzene is shown. The average particle size of the catalyst is 360 mum, the largest angle α in the triangular longitudinal section of the left baffle and the right baffle is 145°. The sides of the prism where the longer side of the triangular longitudinal section of the left baffle and the right baffle of the composite member are located are parallel to each other and placed vertically. The sides of the left baffle and the right baffle of the composite component have holes and (or) slits respectively, and the ratio of the total area of the holes and (or) slits to the area of the blades is 15%. Four composite components are set in the fluidized bed reactor, and the composite components are staggered and evenly distributed in the reactor, and the acute angle / right angle between two adjacent composite components in the vertical direction is 90°, and the vertical direction The vertical distan...

Embodiment 3

[0035] Such as figure 1 The device for producing aniline by hydrogenation of nitrobenzene is shown. The average particle size of the catalyst is 360 mu m, the largest angle α in the triangular longitudinal section of the left baffle and the right baffle is 90°. The sides of the prism where the longer side of the triangular longitudinal section of the left baffle and the right baffle of the composite member are located are parallel to each other and placed vertically. The sides of the left baffle and the right baffle of the composite component have holes and (or) slits respectively, and the ratio of the total area of the holes and (or) slits to the area of the blades is 15%. Four composite components are set in the fluidized bed reactor, and the composite components are staggered and evenly distributed in the reactor, and the acute angle / right angle between two adjacent composite components in the vertical direction is 90°, and the vertical direction The vertical distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com