Method for extracting silicon and aluminum by activating coal gangue through plasma ball milling and vibration fluidization calcination

A plasma ball and fluidization technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high cost, non-conforming to energy saving and environmental protection, and high energy consumption, so as to improve the efficiency of ball milling and achieve ideal dissolution rate , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

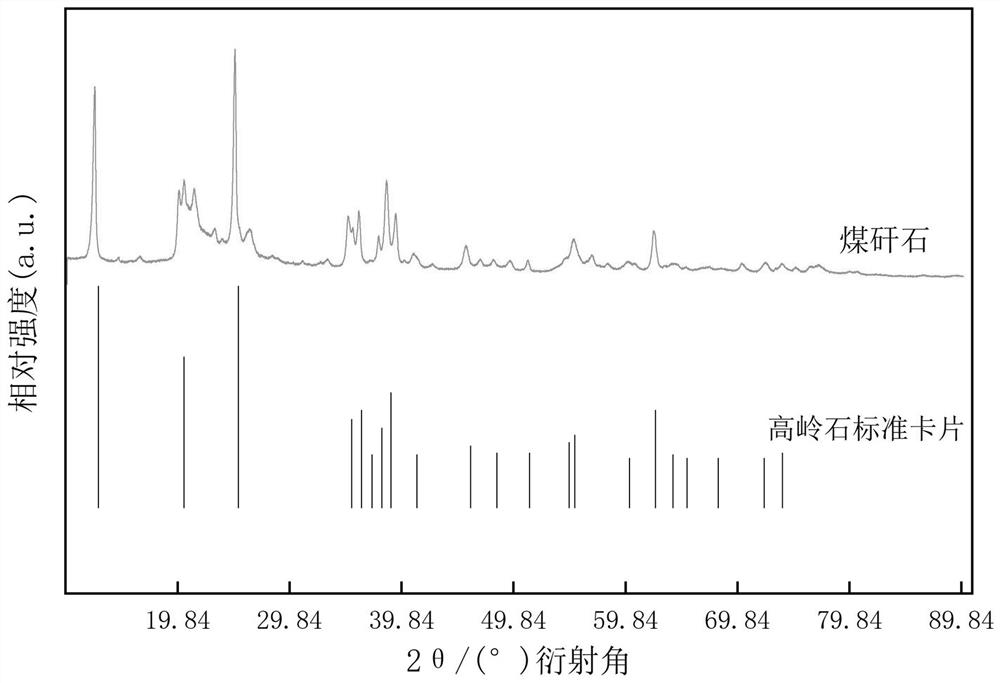

[0026] Embodiment 1: A method for extracting silicon-alumina from coal gangue activated by plasma ball milling plus vibration fluidized calcination, the specific steps are as follows:

[0027] Crush the gangue to a particle size of 10-300 μm and accurately weigh 50 g;

[0028] Weigh 40 g of solid sodium carbonate, mix the weighed solid sodium carbonate with coal gangue powder, set the plasma ball mill vibration motor speed to 800 rpm, discharge voltage to 6 kV, discharge frequency to 20 kHz, and ball-to-material ratio to 30:1 , ball milled for 3 h under nitrogen atmosphere;

[0029] Raise the temperature of the vibrating fluidized bed calciner to 400°C, add the above powder into the vibrating fluidized bed calciner, set the air velocity to 9 cm / s, the vibration frequency of the vibrating table to 15 Hz, and time Calcined for 1 h;

[0030] Prepare a hydrochloric acid solution with a mass concentration of 15%, accurately weigh 525 g, cool the calcined powder for 7200 s, immers...

Embodiment 2

[0032] Embodiment 2: A method for extracting silicon-alumina from coal gangue activated by plasma ball milling plus vibration fluidized calcination, the specific steps are as follows:

[0033] Crush the gangue to a particle size of 10-500 μm and accurately weigh 50 g;

[0034] Weigh 50 g of solid sodium carbonate, mix the weighed solid sodium carbonate with coal gangue powder, set the plasma ball mill vibration motor speed to 1000 rpm, discharge voltage to 8 kV, discharge frequency to 30 kHz, and ball-to-material ratio to 30:1 , ball milled for 3 h under nitrogen atmosphere;

[0035] Raise the temperature of the vibrating fluidized bed calciner to 450°C, add the above powder into the vibrating fluidized bed calciner, set the air velocity to 10 cm / s, the vibration frequency of the vibrating table to 25 Hz, and time Calcination for 2h;

[0036] Prepare a hydrochloric acid solution with a mass concentration of 15%, accurately weigh 600 g, cool the calcined powder for 3600 s, im...

Embodiment 3

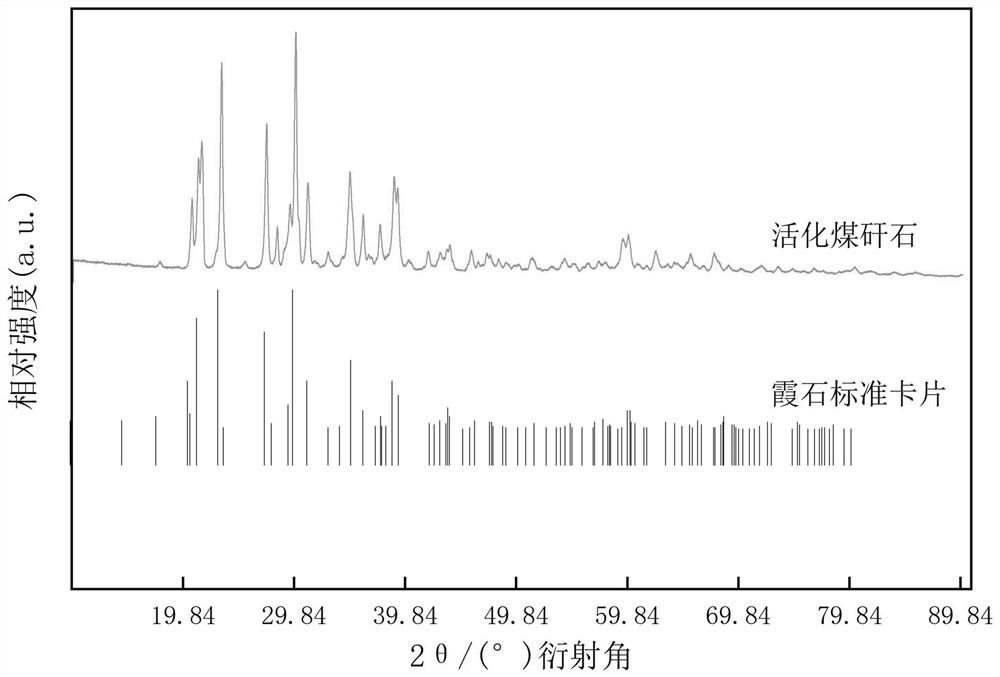

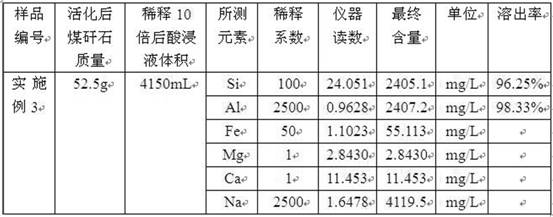

[0038] Embodiment 3: A method for extracting silicon-alumina from coal gangue activated by plasma ball milling plus vibration fluidized calcination, the specific steps are as follows:

[0039] Crush the gangue to a particle size of 10-500 μm and accurately weigh 50 g;

[0040]Weigh 25 g of solid sodium carbonate, mix the weighed solid sodium carbonate with coal gangue powder, set the plasma ball mill vibration motor speed to 1000 rpm, discharge voltage to 8 kV, discharge frequency to 30 kHz, and ball-to-material ratio to 30:1 , ball milled for 3 h under nitrogen atmosphere;

[0041] Raise the temperature of the vibrating fluidized bed calciner to 500°C, add the above powder into the vibrating fluidized bed calciner, set the air velocity to 10 cm / s, the vibration frequency of the vibrating table to 25 Hz, and time Calcined for 2 h;

[0042] Prepare a hydrochloric acid solution with a mass concentration of 15%, accurately weigh 450 g, cool the calcined powder for 10 s, immerse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com