Method and device for realizing zero release in desulfuration wastewater deepening treatment

A desulfurization wastewater, zero-discharge technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems of high price, immature steam compressor technology, and large equipment investment cost. , to achieve the effect of not easy entrainment, ensuring long-term normal operation, and high quality of secondary steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

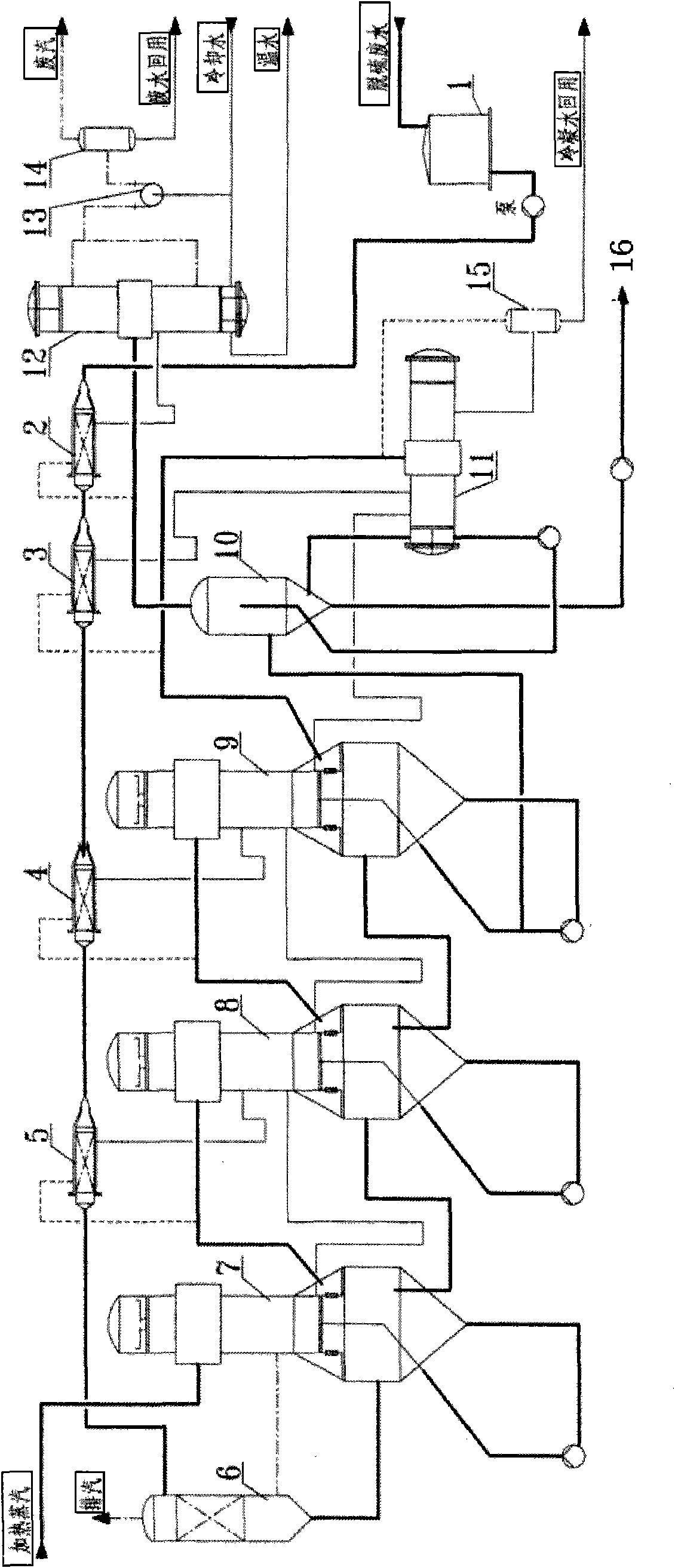

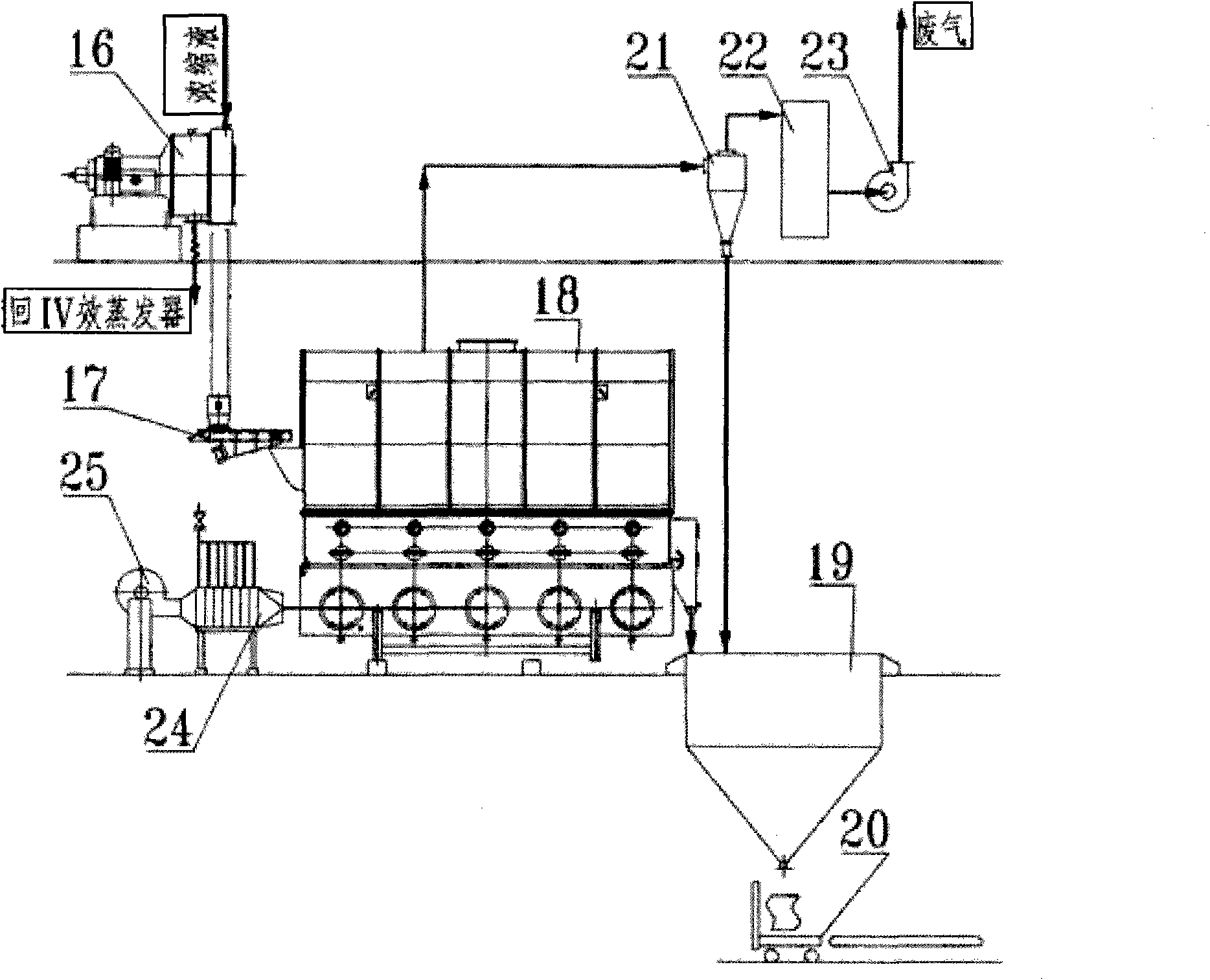

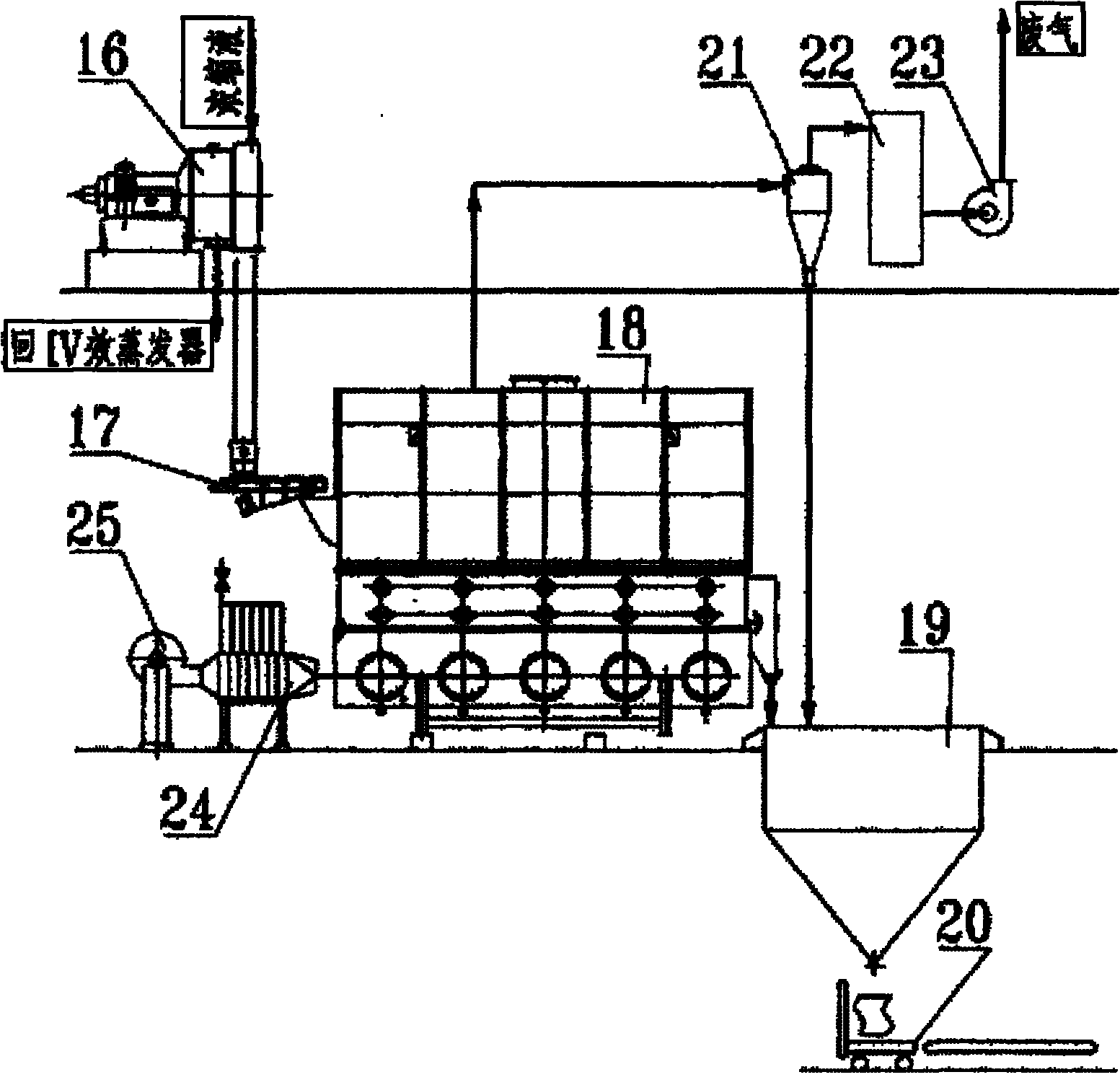

[0020] A device for deep treatment of desulfurization wastewater to realize zero discharge, which is composed of a four-effect evaporation system and a salt drying system. like figure 1 Shown is a schematic diagram of a four-effect evaporation system for the deepening treatment of desulfurization wastewater. The four-effect evaporation system consists of a waste liquid storage tank 1, a first preheater 2, a second preheater 3, a third preheater 4, a fourth preheater 5, a degasser 6, and an I-effect evaporation system. 7, II effect evaporator 8, III effect evaporator 9, IV effect evaporator 10, surface condenser 12, water ring vacuum pump 13, separator 14 and condensed water tank 15. like figure 2 Shown is a schematic diagram of the salt drying system for the deepening treatment of desulfurization wastewater. The salt drying system is composed of a centrifuge 16, a feeder 17, a vibrating fluidized bed dryer 18, an intermediate silo 19, a packaging machine 20, a cyclone sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com