Efficient coal derived pyrite dry-method enrichment process and system

A pyrite and dry process technology is applied in the field of high-efficiency coal-measure pyrite dry enrichment process and system field, which can solve the problems of easy oxidation of sulfur elements, shortage of water resources, and high production costs, and avoid secondary Pollution problems, reduced land use, little effect of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

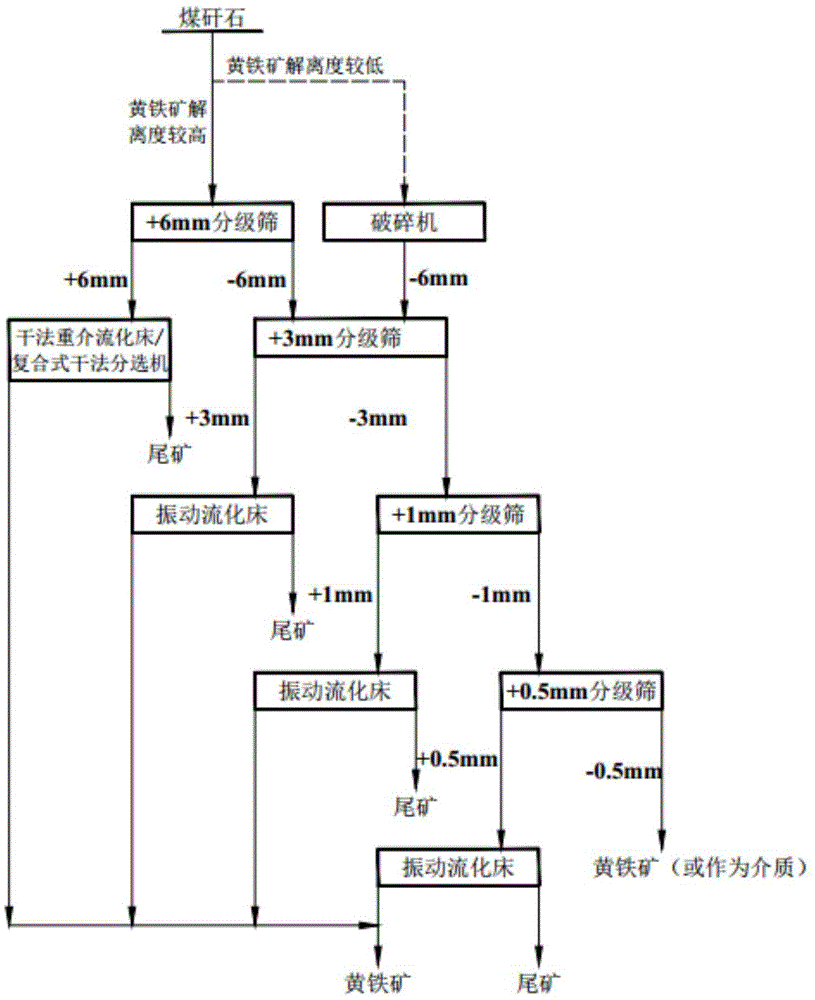

[0031] When the pyrite in the high-sulfur gangue is mainly distributed in coarse-grained aggregates with a high degree of dissociation, no crushing operation is required, and a dry heavy-medium fluidized bed separator / combined dry separator and vibration Fluidized bed separator combined enrichment process.

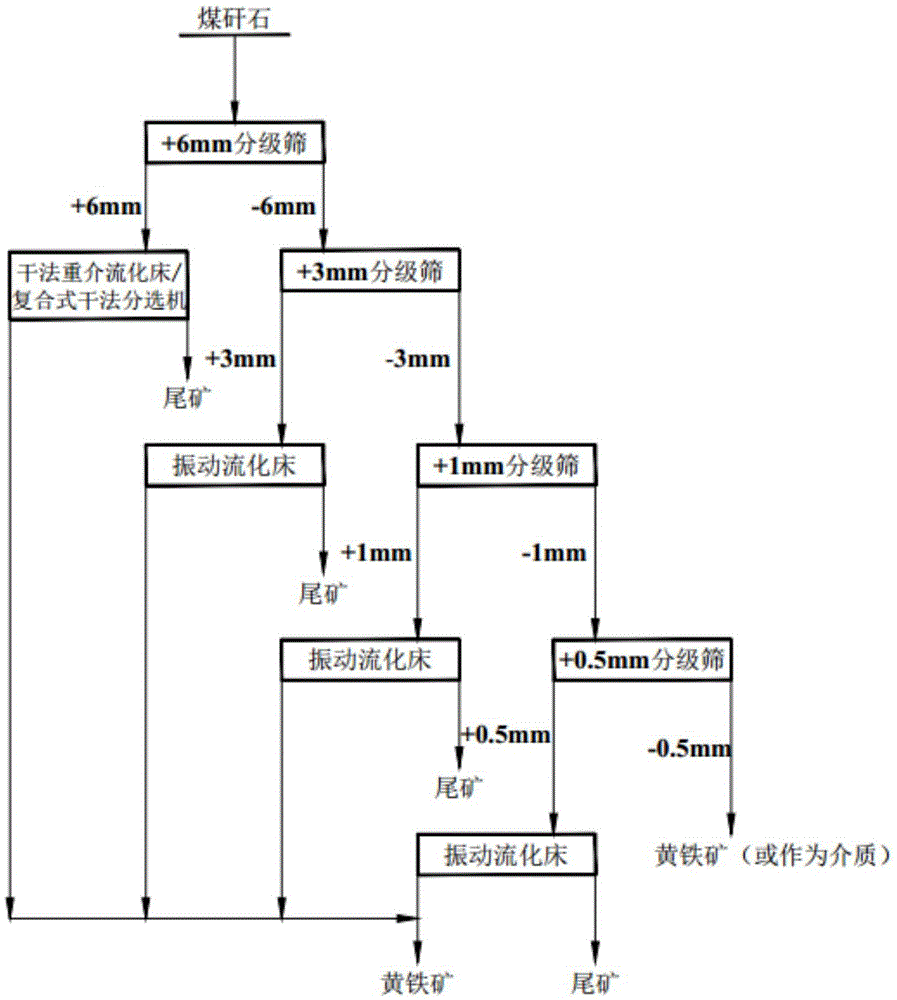

[0032] exist figure 2 Among them, the enrichment process of pyrite in high-sulfur gangue of the present invention mainly includes: material preparation, dry method heavy medium fluidized bed separator / compound dry method separator, vibrating fluidized bed separator Choose three parts. The material preparation part includes grading screen and buffer bin; the sorting part includes dry heavy medium fluidized bed sorter / combined dry sorter vibrating fluidized bed sorter sorter. Specific steps are as follows:

[0033] (1) Material preparation: Use a 6mm grading sieve to divide the material to be selected (high-sulfur coal gangue) into two particle size grades of +6mm and -6...

Embodiment 2

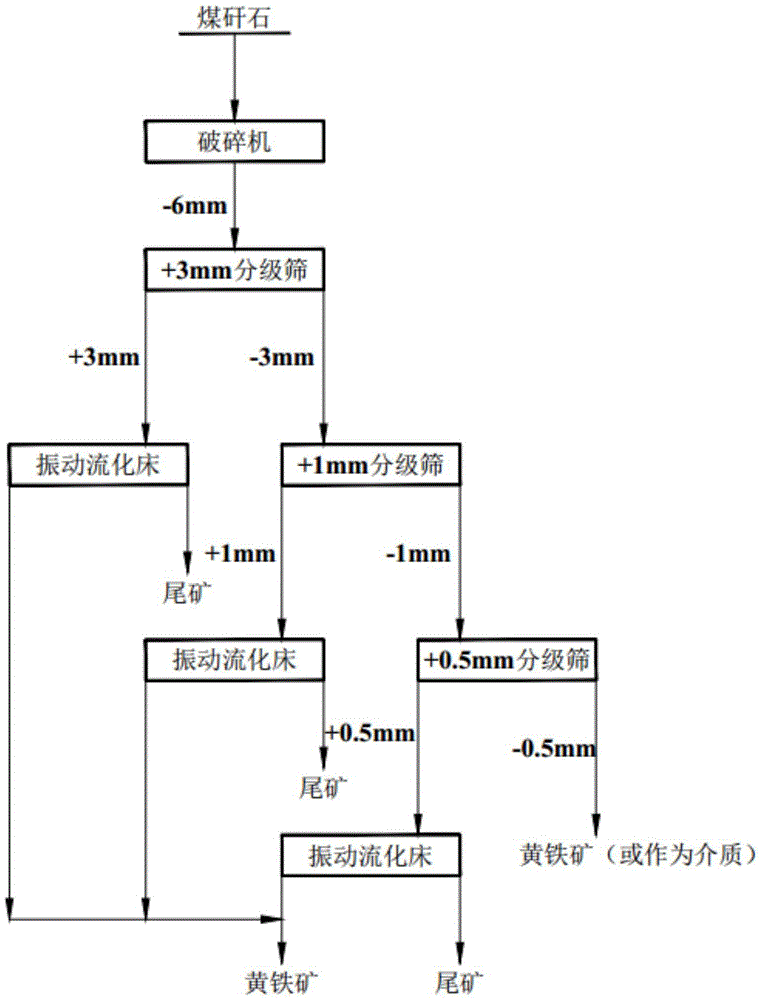

[0038] When the pyrite in the high-sulfur gangue has a fine particle size and a low degree of dissociation, the sample is first crushed and dissociated, and the vibrating fluidized bed separator is directly used to enrich the sulfur iron in the fine-grained high-sulfur gangue mine.

[0039] exist image 3 Among them, the enrichment process of pyrite in high-sulfur gangue of the present invention mainly includes two parts: material preparation and vibrating fluidized bed sorting machine sorting. The material preparation part includes grading screen and buffer bin; the sorting part of vibrating fluidized bed separator includes vibrating fluidized bed sorting machine. Specific steps are as follows:

[0040] (1) Material preparation: Use a crusher to crush the material to be selected (high-sulfur coal gangue) to -6mm, and sieve the -6mm material into -6+3mm, -3+1mm, -1+0.5mm, -0.5 There are four grades of mm, and the screened material is sent to the buffer bin; the -0.5mm mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com