Method and system for performing drying and dry distillation on fluidized bed pulverized coal based on overheating steam medium

A superheated steam, fluidized bed technology, applied in the direction of direct heating dry distillation, heating to dry solid materials, special forms of dry distillation, etc. problems such as uniformity, to achieve the effect of reducing energy consumption, low water content, and uniform water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

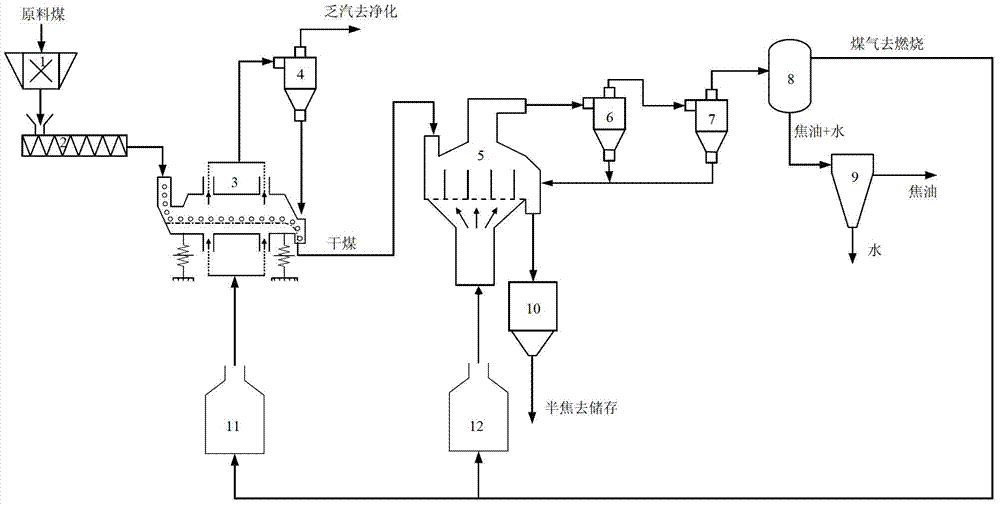

[0025] Embodiment 1: as figure 1 As shown, the pulverized coal processing capacity of the present embodiment is 0.5t / h, and the lignite with an average particle size of about 2.0mm and a base moisture content of 20% is used as a raw material. The specific implementation method includes the following steps:

[0026] (1) The lignite raw coal is crushed by the crusher 1 until the particle size is below 3 mm, and then sent to the vibrating fluidized bed 3 for drying by the screw conveyor 2;

[0027] (2) The lignite particles are evenly distributed on the porous bottom plate of the vibrating fluidized bed 3, and the superheated steam heats and dries the lignite through the porous plate, and the coal particles are evenly fluidized and dried quickly under the action of mechanical vibration force and superheated steam. The furnace temperature of the superheated steam in the vibrating fluidized bed 3 is 200°C, the residence time of lignite in the vibrating fluidized bed 3 is 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com