Method for decomposing phosphogypsum through coupling reaction heat and vibration fluidizing

A thermally coupled, vibrating fluidized bed technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve problems affecting production continuity, difficult decomposition of phosphogypsum, and utilization rate of less than 10%, to achieve favorable Industrial operation, not easy to agglomerate, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Take 500 g of pretreated phosphogypsum powder, add additives in an amount of 12.5% of the weight of phosphogypsum, and then add and mix evenly according to the weight ratio of phosphogypsum and coke to obtain a mixture;

[0021] The pretreated phosphogypsum; the pretreatment method is: drying the phosphogypsum at a temperature of 110°C to remove free water, then drying at a temperature of 650°C to remove crystal water, and passing through an 80-mesh sieve to obtain Phosphogypsum after pretreatment;

[0022] The additive is made of SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Prepared, the mass percentage of each component: SiO 2 50%, Fe 2 o 3 10%, CaO 20%, MgO 8%, Al 2 o 3 12%, each component is evenly mixed and passed through an 80-mesh sieve to obtain the additive.

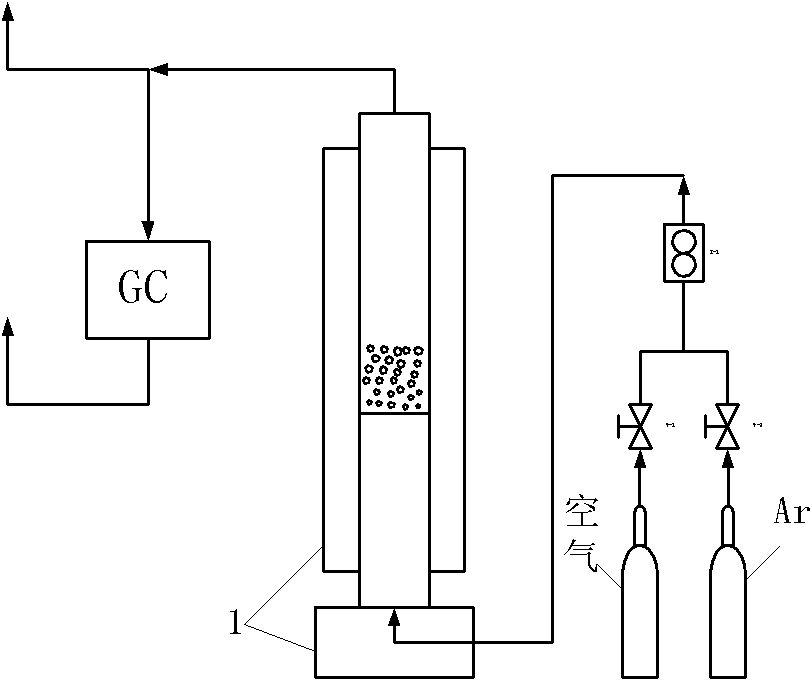

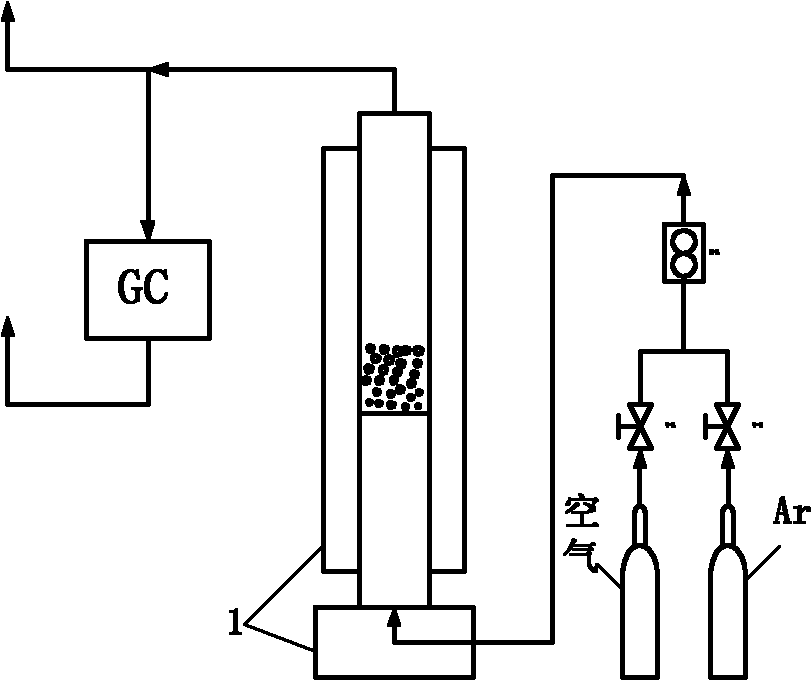

[0023] 2) Put the mixed material into the vibrating fluidized bed, and program the temperature to 1020°C under the protection of Ar atmosphere (the heating rate is 17°C / min). After rising to ...

Embodiment 2

[0027] 1) Take 500 g of pretreated phosphogypsum powder, add additives in an amount of 12.5% of the weight of phosphogypsum, and then add and mix evenly according to the weight ratio of phosphogypsum and coke to obtain a mixture;

[0028] The pretreated phosphogypsum; the pretreatment method is: drying the phosphogypsum at a temperature of 110°C to remove free water, then drying at a temperature of 650°C to remove crystal water, and passing through an 80-mesh sieve to obtain Phosphogypsum after pretreatment;

[0029] The additive is made of SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Prepared, the mass percentage of each component: SiO 2 40%, Fe 2 o 3 17%, CaO 20%, MgO 6%, Al 2 o 317%, each component is evenly mixed and passed through an 80-mesh sieve to obtain the additive.

[0030] 2) Place the mixed material in a vibrating fluidized bed, and program the temperature to 1020°C under the protection of Ar atmosphere (the heating rate is 20°C / min). The volume concentr...

Embodiment 3

[0033] 1) Take 500 g of pretreated phosphogypsum powder, add additives in an amount of 12.5% of the weight of phosphogypsum, and then add and mix evenly according to the weight ratio of phosphogypsum and coke to obtain a mixture;

[0034] The phosphogypsum is pretreated phosphogypsum; the pretreatment method is: drying the phosphogypsum at a temperature of 90°C to remove free water, then drying at a temperature of 450°C to remove crystal water, and passing through 40 mesh Sieve to obtain pretreated phosphogypsum;

[0035] The additive is made of SiO 2 , Fe 2 o 3 , CaO, MgO and Al 2 o 3 Prepared, the mass percentage of each component: SiO 2 60%, Fe 2 o 3 5%, CaO 15%, MgO 10%, Al 2 o 3 10%, each component is evenly mixed and passed through an 80-mesh sieve to obtain the additive;

[0036] 2) Put the mixed material into the vibrating fluidized bed, and program the temperature to 1020°C under the protection of Ar atmosphere (the heating rate is 17°C / min). The volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com