Vibrational fluidized bed device for controlling humidity and grading coking coal and fluidizing process thereof

A vibrating fluidized bed and humidity control technology, applied in coking ovens, separating solids from solids with airflow, solid separation, etc., can solve the complex structure of the scraper machine, poor stratification of the fluidized bed, and low separation accuracy and other problems, to achieve the effect of obvious drying effect, uniform fluidization and high separation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

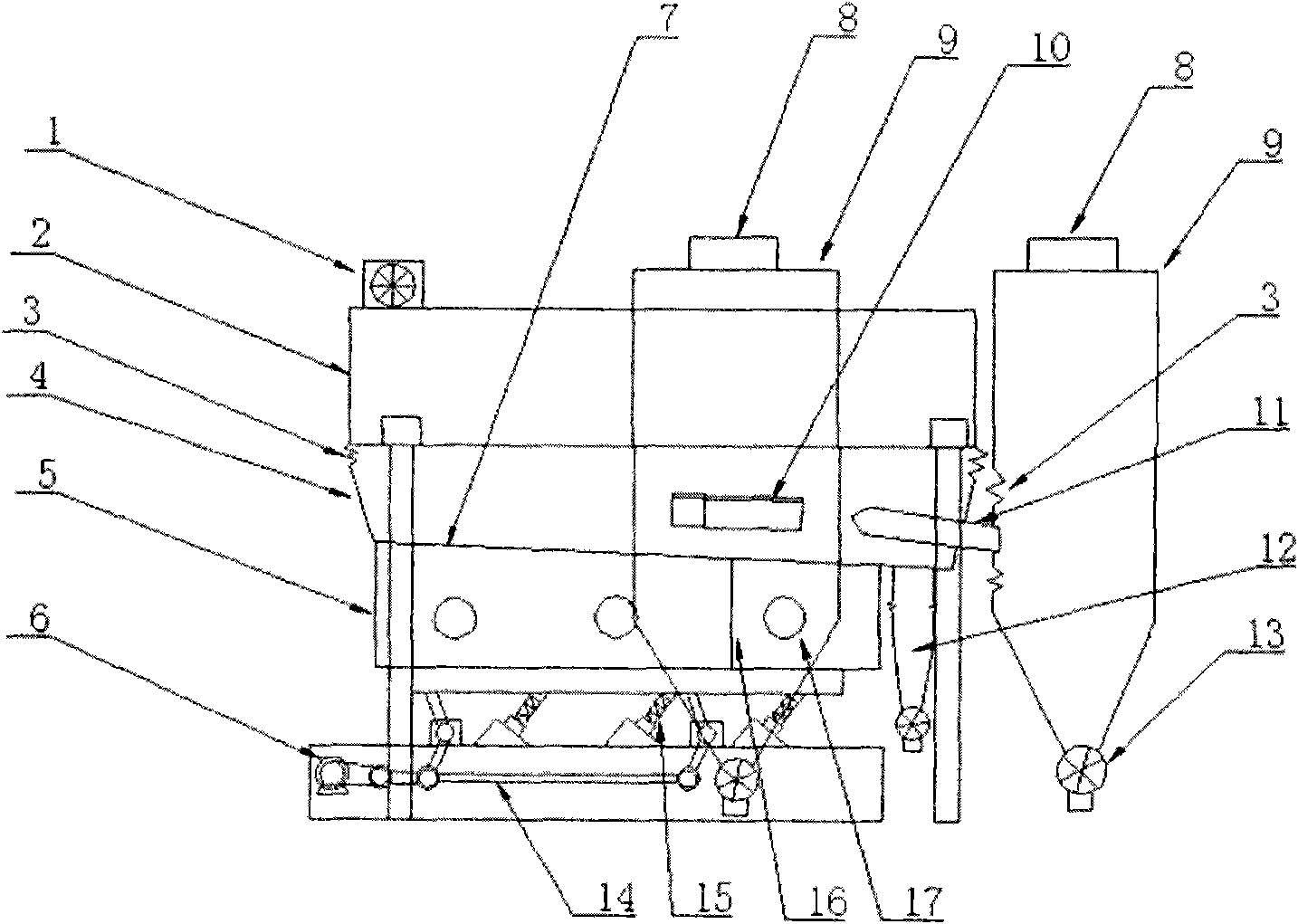

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

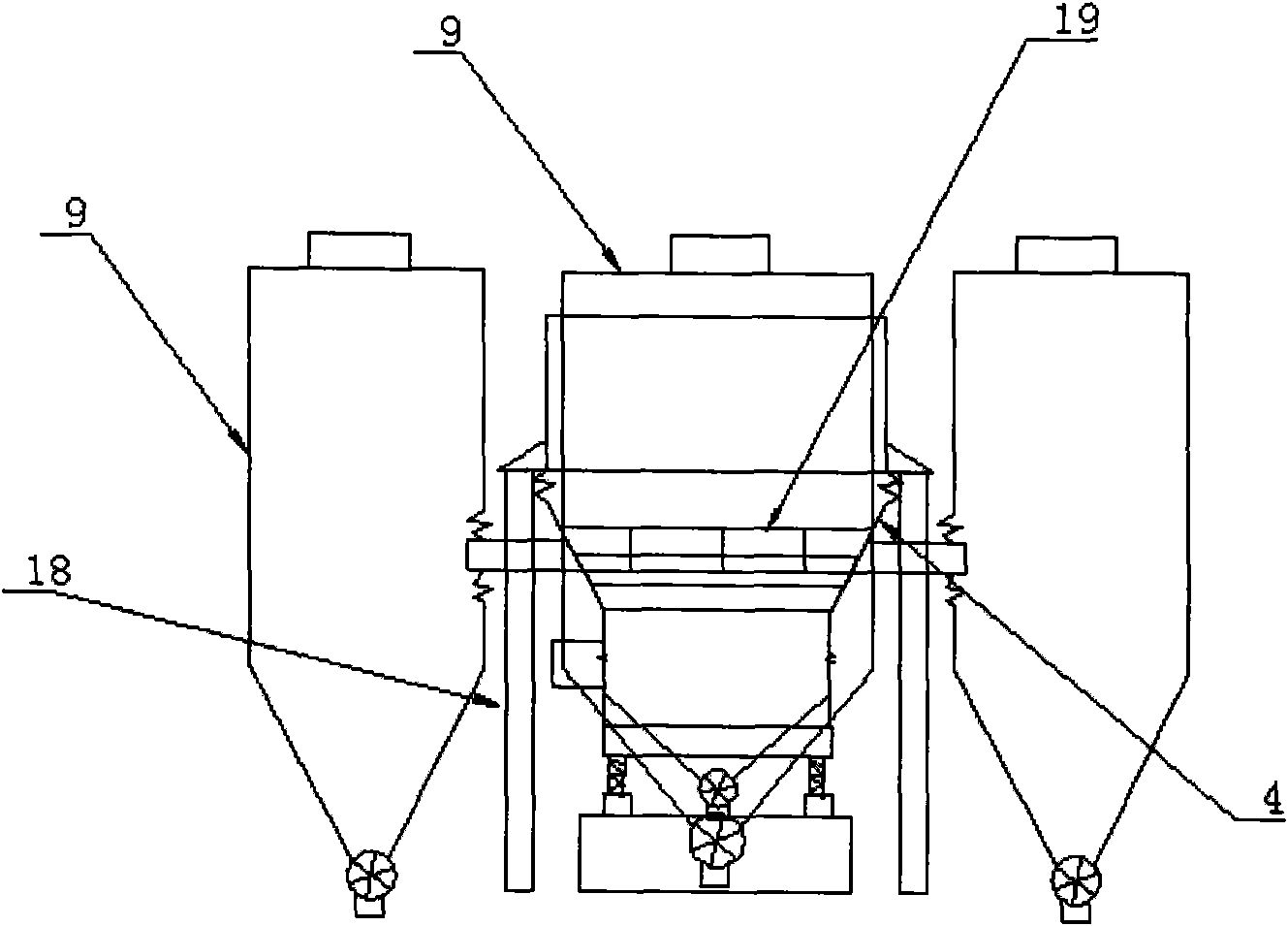

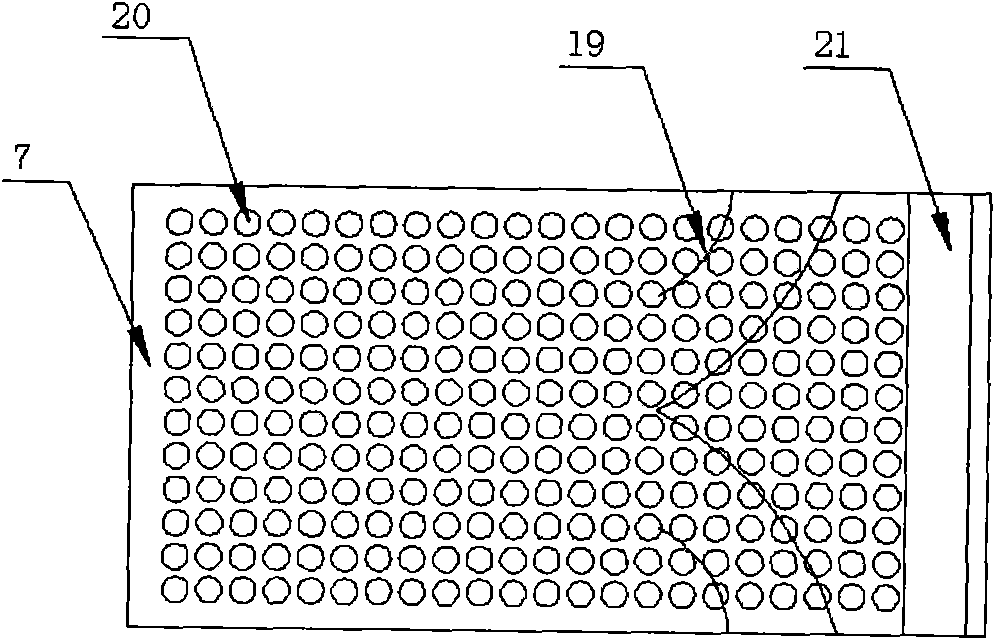

[0037] Such as figure 1 , 2 , 3, the present invention includes a feeding port 1, a cover body 2, a baffle plate 4, an uneven pressure bellows 5, a linear drive device, an air distribution plate 7, an air outlet 8, an air material separation chamber 9, and an air outlet 10. Large-grained coal collection chamber 12, sealed power unloading device 13, air inlet 17, supporting steel beam 18, arc-shaped fine-grained coal scraper 19, and large-grained coal outlet 21, wherein the linear drive device is composed of a transmission rod 14 and a supporting spring 15 And driving motor 6 forms.

[0038] The fluidized drying and grading chamber is supported by supporting steel beams 18, the feeding port 1 is located on the cover body 2, and is equipped with a sealed feeder for quantitative and uniform feeding;

[0039] The uneven pressure air box 5 is divided into two parts by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com