Lignite drying system and lignite drying method

A technology of drying system and drying method, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of low drying efficiency, volatile matter precipitation, and high volatile matter of lignite, so as to avoid oversaturation and reduce Oxygen content, effect of preventing overdrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

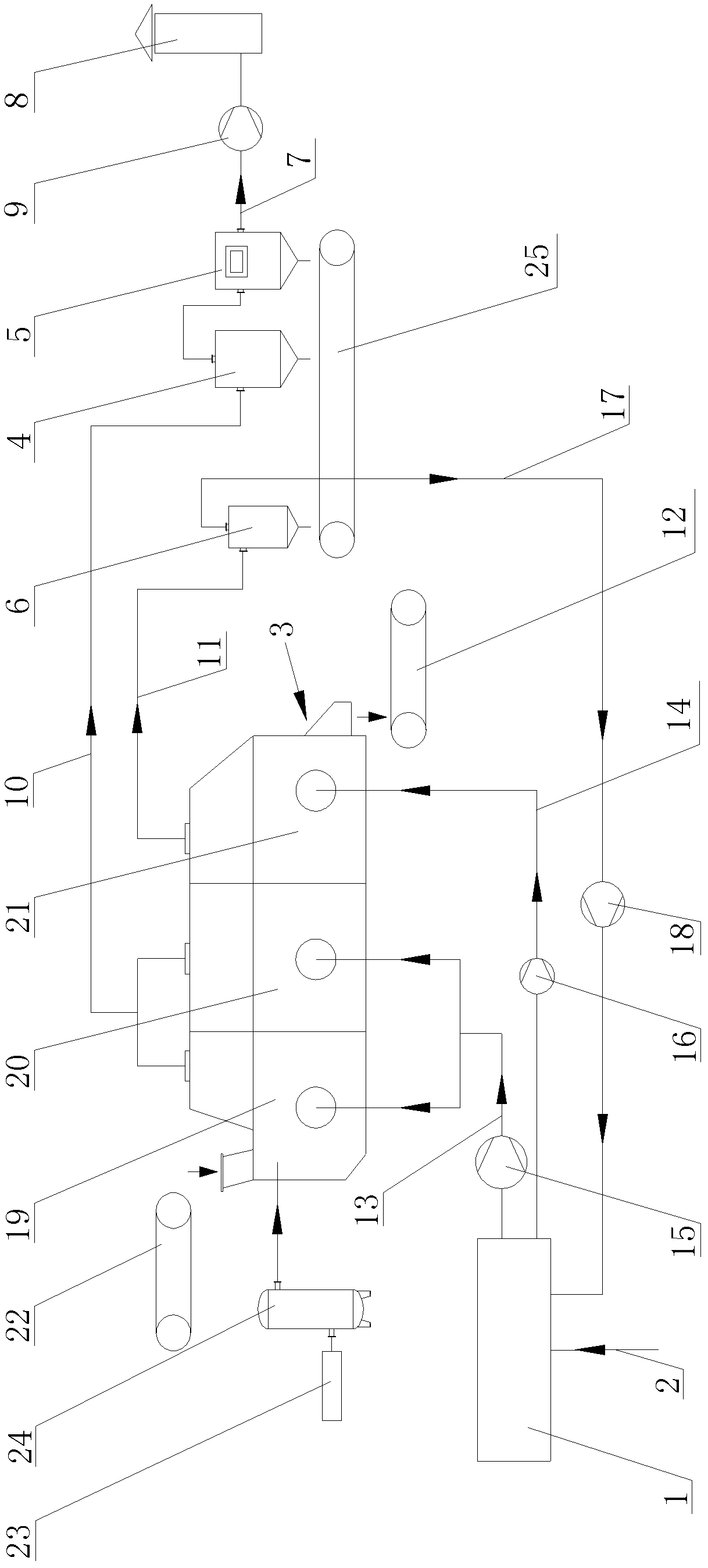

[0037] Such as figure 1 As shown, the lignite drying system of the embodiment of the present invention is used to dry lignite materials with a particle size range below 50mm, including a hot air system, a vibrating fluidized bed dryer 3, a nitrogen system and a dust removal system, wherein the hot air The system includes a flue gas generator 1. The flue gas generator 1 has a combustion chamber and an air mixing chamber. The high temperature flue gas generated by the combustion chamber is fully mixed with the air entering from the air duct 2 in the air mixing chamber to form working flue gas. , the working flue gas enters the vibrating fluidized bed dryer 3 under the action of the blower through the air inlet pipe to dry the coal material, and the flue gas generator 1 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com