Vibratory air dense media fluidized bed dry method sorting machine

A technology of vibrating fluidized bed and air-dense medium, which is applied in the direction of separating solids from solids by air flow, chemical instruments and methods, solid separation, etc., which can solve mesh blockage, chain service life reduction, and overall air distribution plate To avoid damage and other problems, to achieve stable operation, prevent blockage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

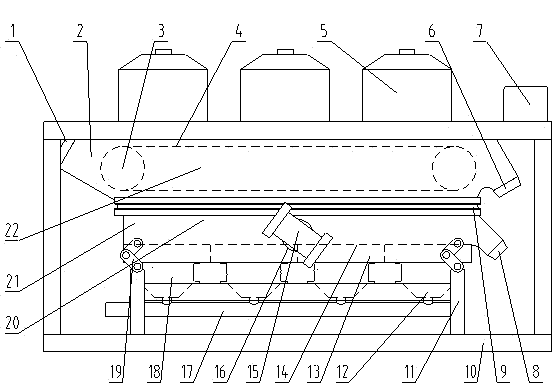

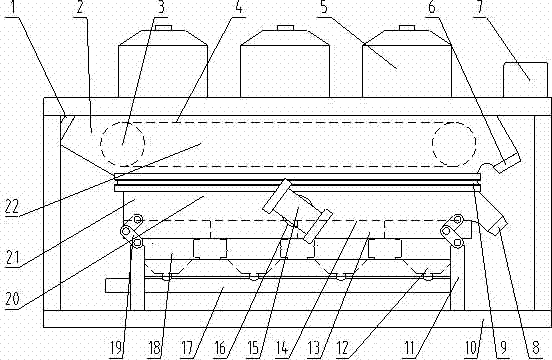

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0010] The vibrating air dense medium fluidized bed dry separation machine of the present invention is mainly composed of a floating object discharge device 22, a sinking object discharge device 20, a first-stage air distribution chamber 13, a frame 10, legs 11, an annular flexible The connecting piece 9, the cylindrical flexible connecting piece 18, and the torsion spring 19 are formed. The sinking object discharge device 20 is arranged under the floating object discharge device 22. The floating object discharge device 22 is composed of a casing 2, a scraper sprocket 3, a scraper chain 4, and a motor 7, and the motor 7 is fixed on the frame 10. , for driving the scraper sprocket, three dust-removing air-introduction covers 5 are evenly distributed above the casing 2, and the casing 2 is connected with the frame 10 by bolts. The sink discharge device 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com