Vibration fluidization drying system

A drying system and vibration fluidization technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of good fluidity, fluidized drying, easy to be affected by moisture, etc., and achieve the effect of improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

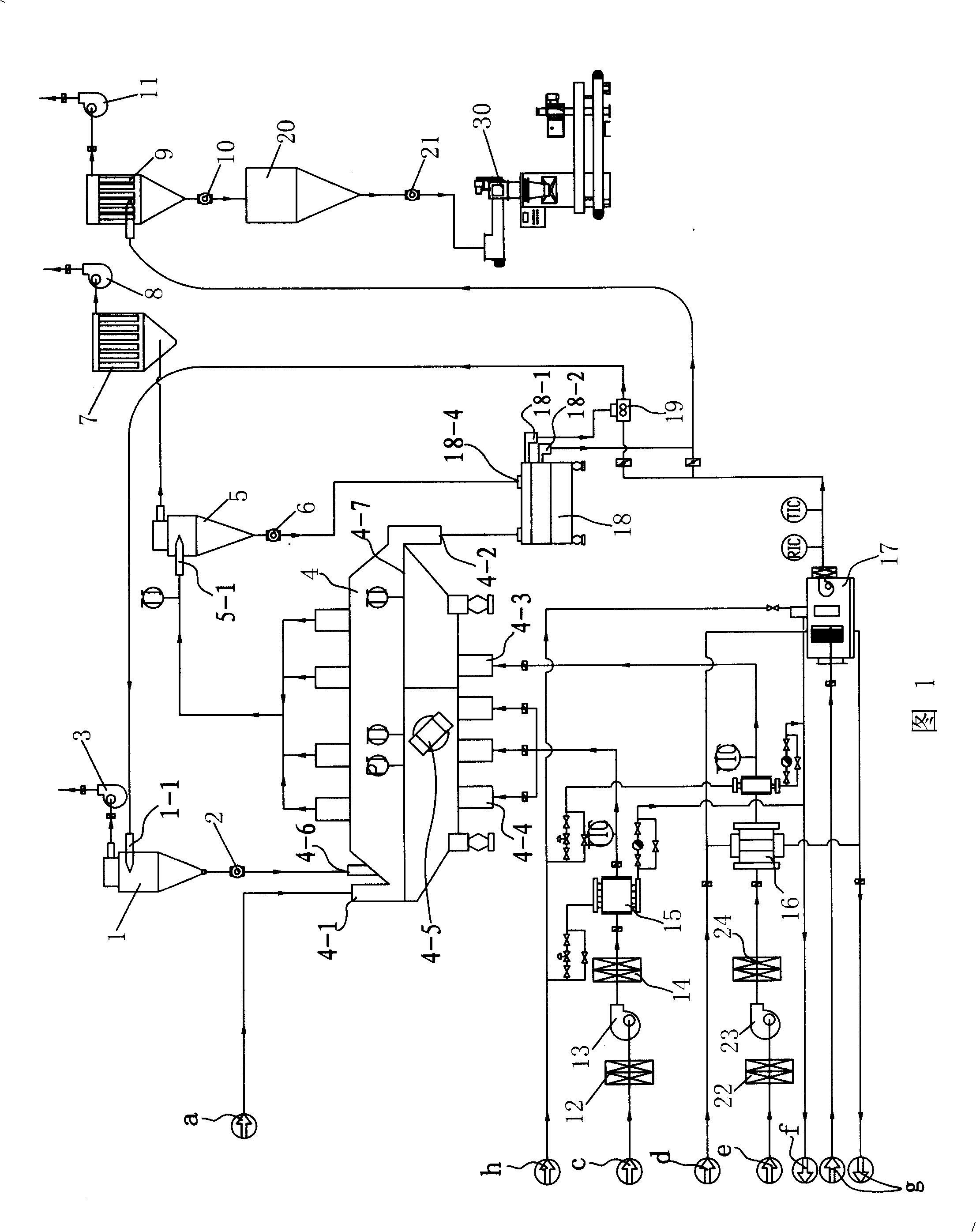

[0015] See Fig. 1, the vibrating fluidized drying system of the present embodiment comprises: vibrating fluidized bed 4, the vibrating screen 18 that links to each other with the outlet 4-2 of vibrating fluidized bed 4, monolith breaker 19, the first gas-solid Separator 1 and first shut-off fan 2, second gas-solid separator 5 and second shut-off fan 6, automatic packaging system, combined dehumidifier 17 for outputting low-temperature dry airflow.

[0016] The vibrating fluidized bed 4 is provided with a vibrating motor 4-5 and a bed board 4-7 with ventilation holes, and the bed board 4-7 is provided with an air pressure sensor PI and a temperature sensor TI. One end of the vibrating fluidized bed 4 is a material inlet 4-1, and the other end is a material outlet 4-2. The feed port 4-1 is connected with the feed pipeline a. RIC in Figure 1 is an instant conditioning sterilization device, and TIC is a temperature indicating regulator.

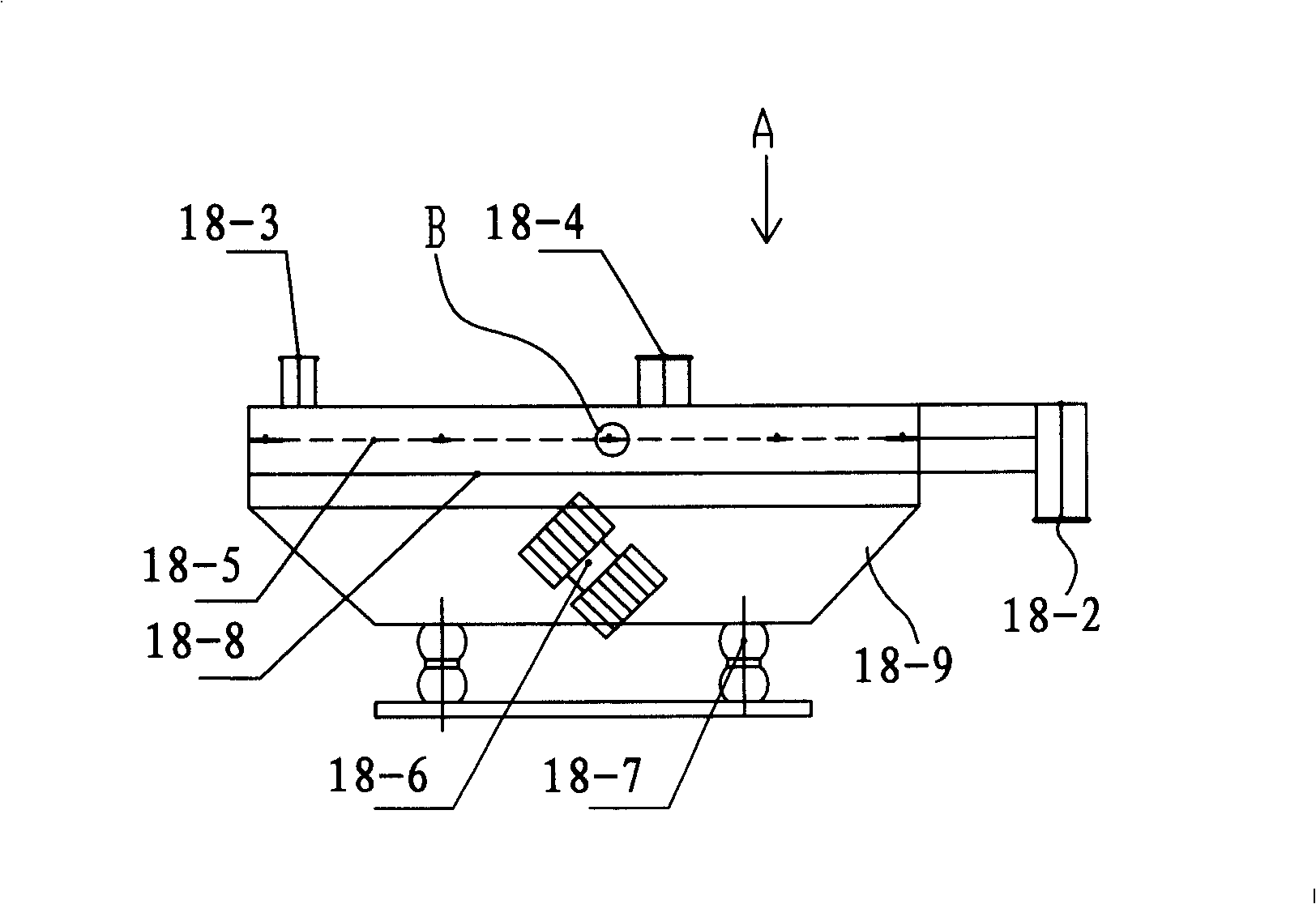

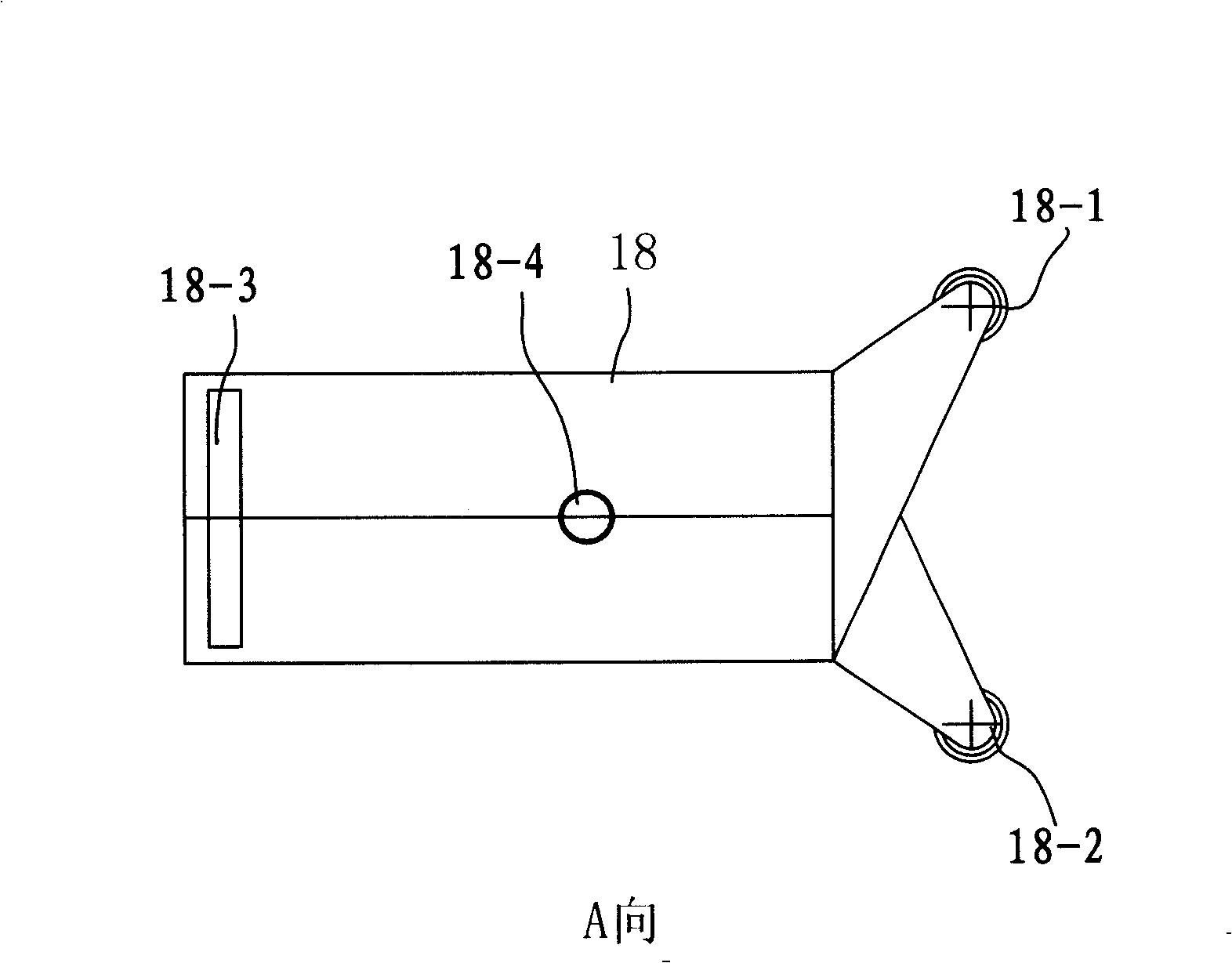

[0017] See Figure 2-3 , The vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com