Automatic feeding device for wood block precision carving machine

A technology of automatic feeding and engraving machine, applied in the direction of engraving, decorative arts, processing models, etc., can solve the problems of low production efficiency, misalignment of wood blocks and positioning channels, and high labor costs, to ensure efficiency and avoid position. the effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

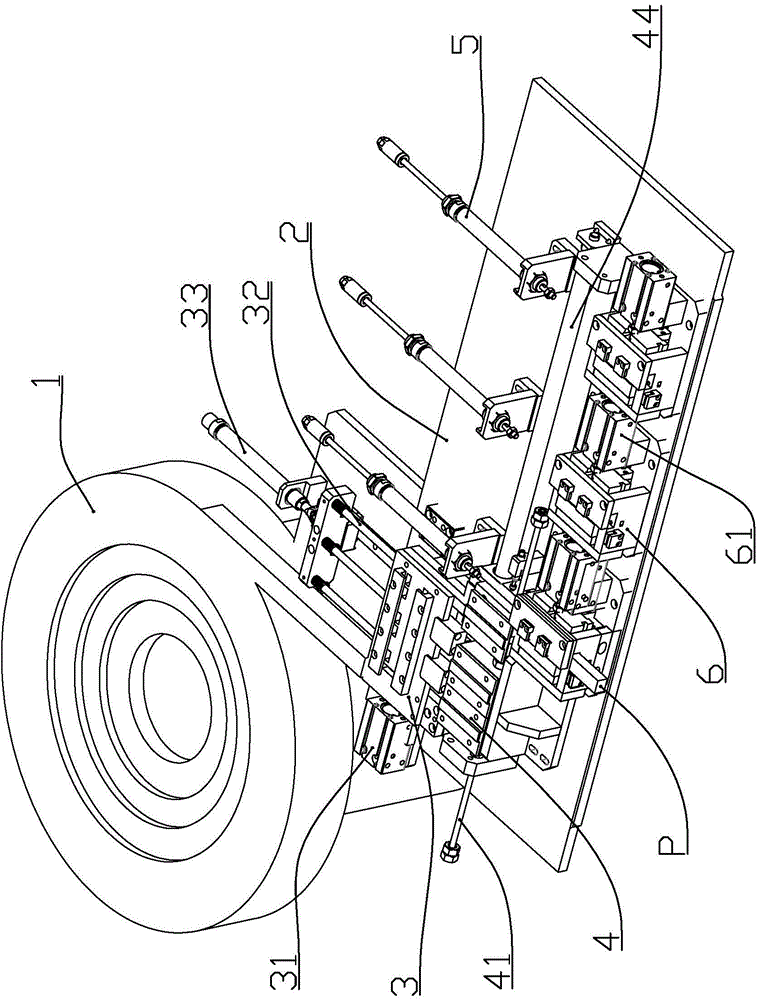

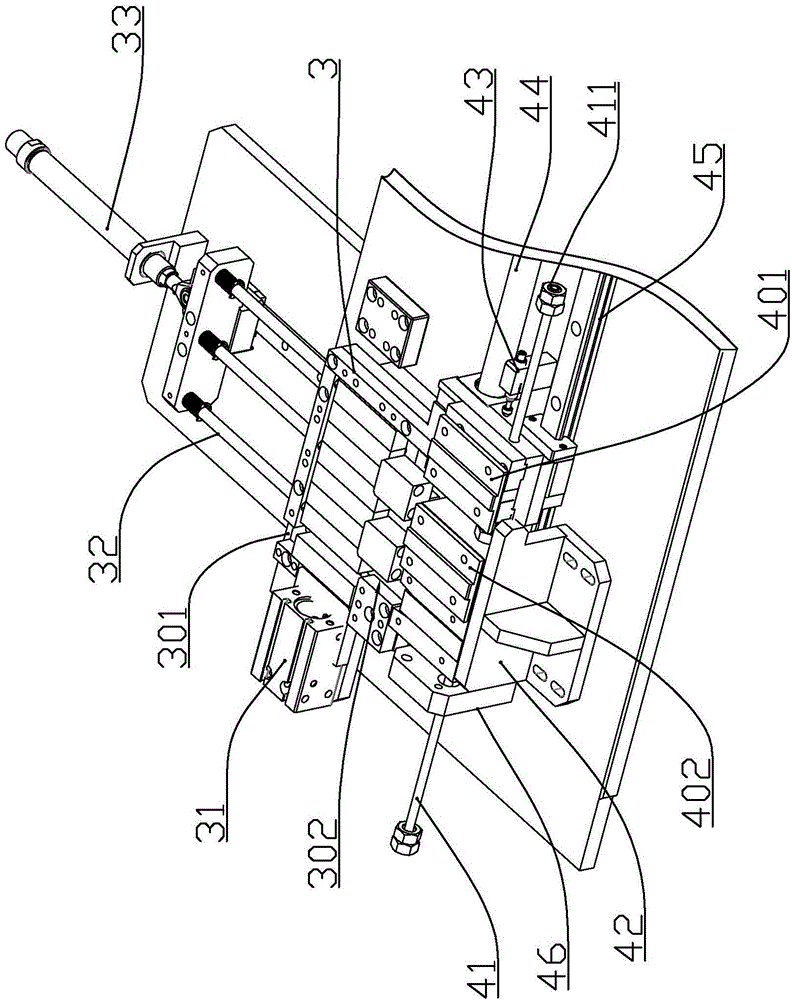

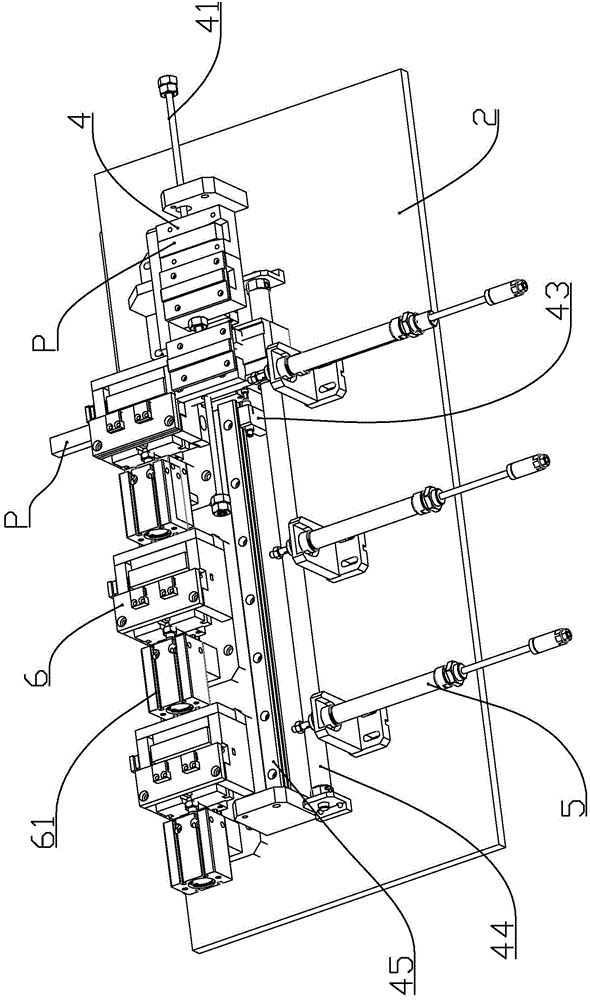

[0020] according to Figure 1 to Figure 5 As shown, this embodiment is an automatic feeding device for wood block engraving machines, including a base 2, a vibrating plate 1 for feeding wood blocks at one end of the base; fixedly installed on the base and connected to the vibration A material storage channel 3 for wood block storage connected to the disc discharge port; a plurality of clamping positioning seats 6 for fixing wood blocks fixedly installed on the base and arranged in a linear array; slidingly installed on the base A plurality of distributing seats 4 for conveying a plurality of wood blocks from the storage channel to each clamping positioning seat at the same time; The material distribution seat is pushed to the third pushing cylinder 5 on the clamping positioning seat.

[0021] The storage channel is perpendicular to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com