Electric toothbrush head dynamic feeding system based on vision

An electric toothbrush and brush head technology, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of poor flexibility, large floor space, and high cost, reduce moving distance, improve grasping efficiency, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

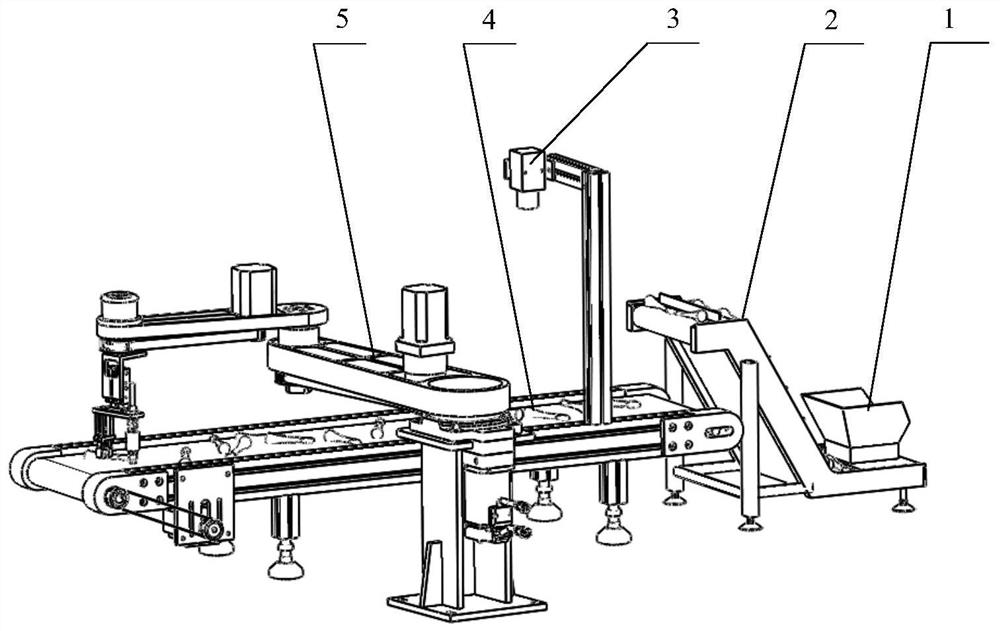

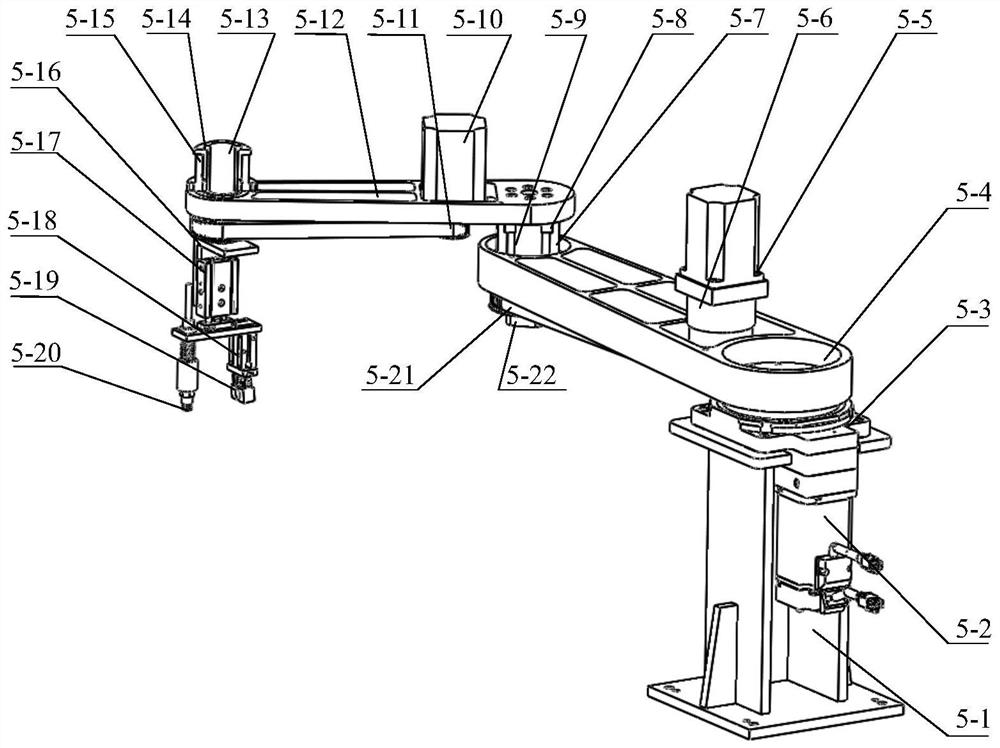

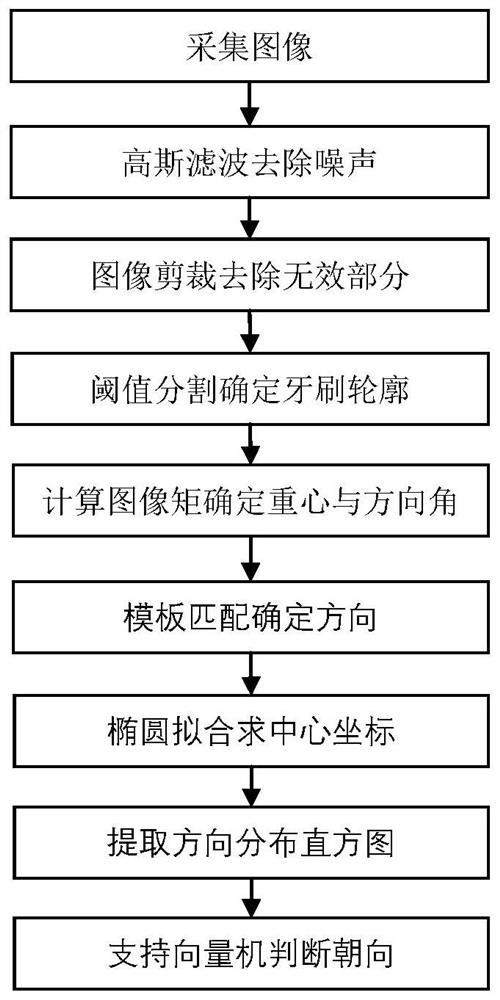

[0076] Such as figure 1 As shown, the present invention provides a vision-based dynamic feeding system for electric toothbrush heads, including a conveying device, an image acquisition module, a vision processing module and a control module. The conveying device includes a hopper 1, an elevator 2 and a conveyor belt 4, and the hopper is installed at the front end of the elevator 2. Image acquisition includes an industrial camera 3, a light source, and a camera bracket. The visual processing module includes toothbrush head identification and positioning software. The control module includes a robot 5, an end gripper and a motion controller.

[0077] The robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com