Umbrella handle rod automatic continuous stamping equipment

A technology of stamping equipment and umbrella handle, applied in the field of automatic continuous stamping equipment for umbrella handle rods, can solve the problems of unstable product quality, low production efficiency, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

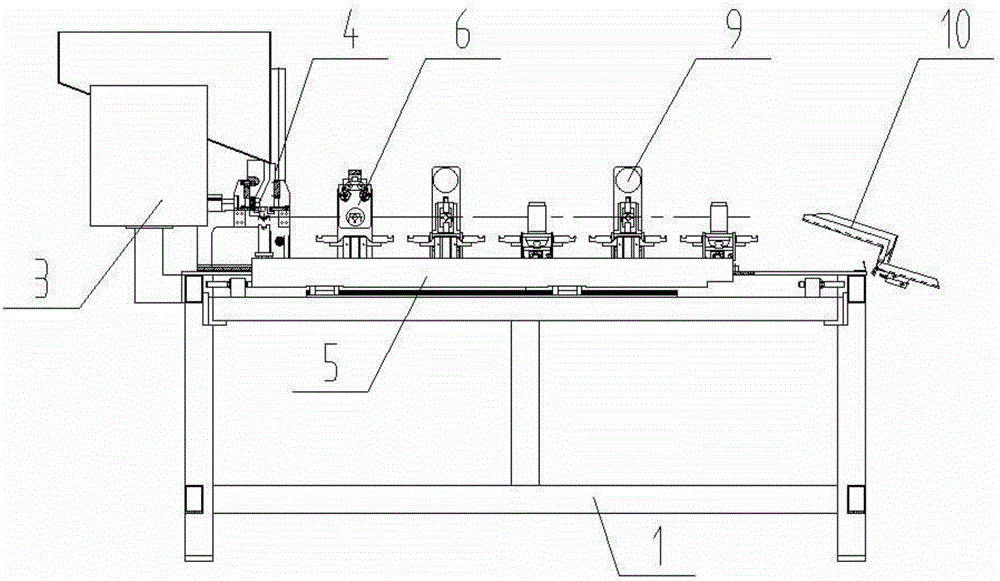

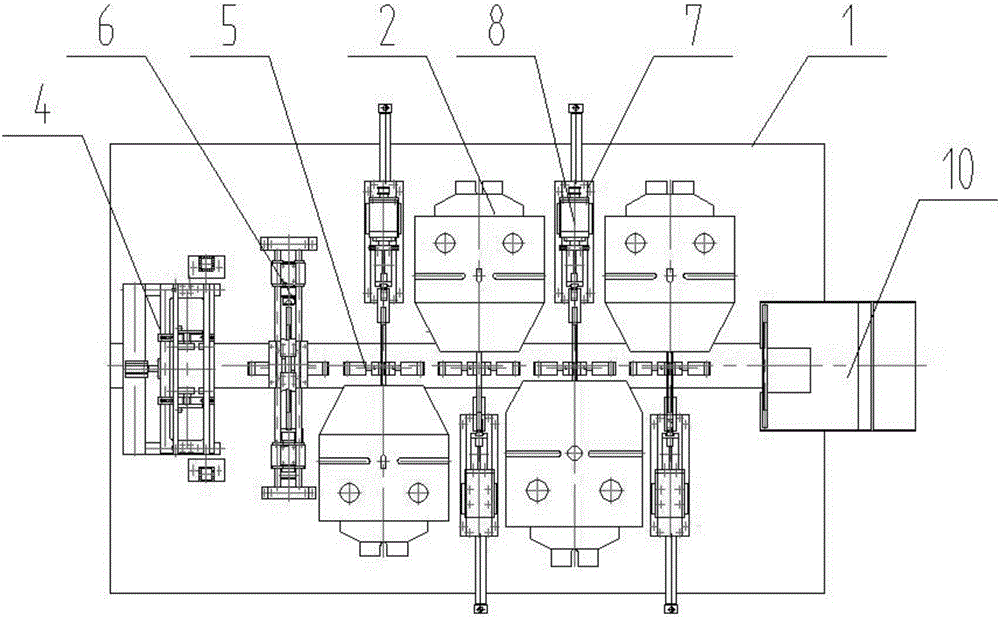

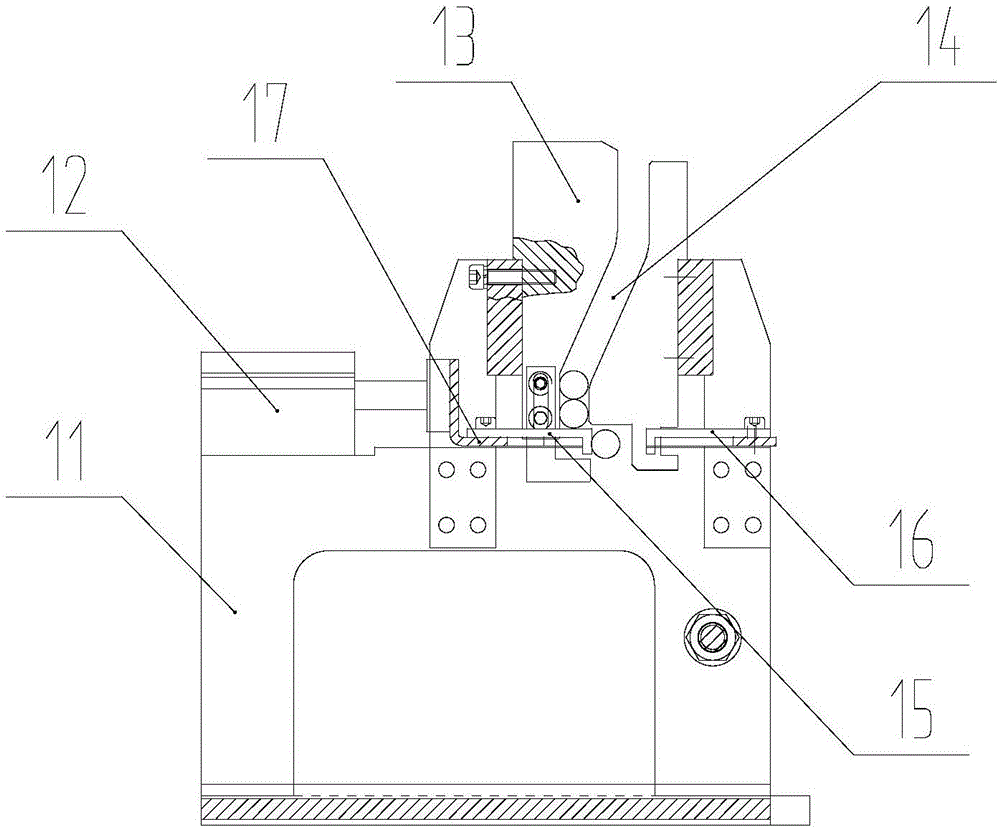

[0051] Such as figure 1 and figure 2 As shown, an automatic continuous punching equipment for umbrella handles is used to punch out four holes with different positions in the circumferential direction and different positions from the end face at both ends of the umbrella handle to be processed, including The automatic feeding module 4 for automatic feeding one by one, the output module 10 for receiving the finished umbrella handles to be processed, supporting and clamping the umbrella handles to be processed and feeding them by the automatic feeding module 4 The X-direction reciprocating feeding module 5 sent to the direction of the discharge module 10, the symmetrical clamping and circumferential positioning module for clamping and determining the zero position of the passed umbrella handle to be processed 6, and the processing of the passed umbrella handle to be processed The Y-direction feed processing module 9 for Y-direction feeding and punching, the digital control mod...

Embodiment 2

[0073] Such as figure 1 and figure 2 As shown, an automatic continuous punching equipment for umbrella handles is used to punch out four holes with different positions in the circumferential direction and different positions from the end face at both ends of the umbrella handle to be processed, including The automatic feeding module 4 for automatic feeding one by one, the output module 10 for receiving the finished umbrella handles to be processed, supporting and clamping the umbrella handles to be processed and feeding them by the automatic feeding module 4 The X-direction reciprocating feeding module 5 sent to the direction of the discharge module 10, the symmetrical clamping and circumferential positioning module for clamping and determining the zero position of the passed umbrella handle to be processed 6, and the processing of the passed umbrella handle to be processed The Y-direction feed processing module 9 for Y-direction feeding and punching, the digital control mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com