Roller-slitting grinding mill feeding and discharging assembly

A grinder and roller cutting technology, which is applied in the field of ultra-fine crushing of non-metallic minerals, can solve the problems of inability to realize automatic feeding and discharging, increase the workload of the operator, and the inability to roll the feeding material, so as to facilitate effective operation , Improve the grinding efficiency and reduce the working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

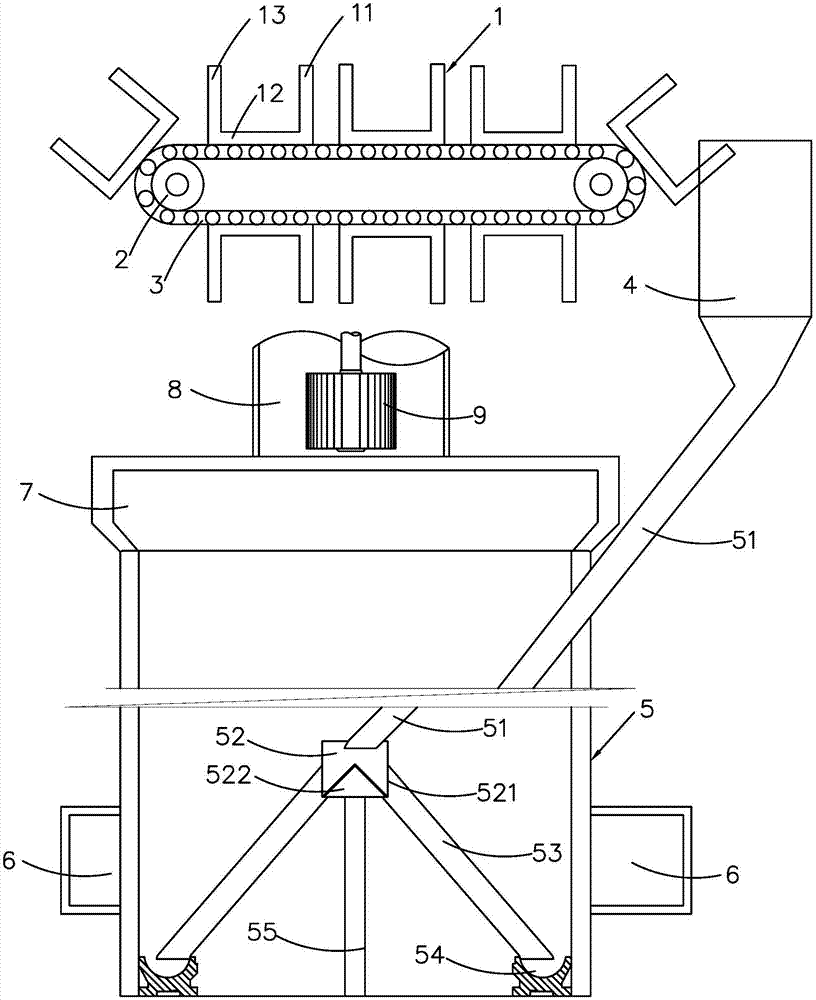

[0022] Such as figure 1 As shown, the feeding and unloading assembly of the roller cutting grinder includes a transmission device and a feeding device, and the transmission device is connected to the feeding device; Card slot 1; the feeding device includes a first feed bin 4 connected to the feed slot 1, a grinding bin 5, a decompression chamber 7 above the grinding bin 5, and an air outlet pipe at the top of the decompression chamber 7 8, and the air inlet pipe 6 surrounding the outside of the grinding chamber 5;

[0023] Described grinding bin 5 comprises feed pipe 51, the second feed bin 52, discharge pipe 53 and U-shaped ring groove 54 that its inside is provided with, and the feeding port of feed pipe 51 stretches out the side of grinding bin 5 and is connected with The discharge port of the first feed bin 4 is fixedly connected, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com