Low-fish meal bullfrog compound feed, and preparation method and application thereof

A technology of compound feed and low fish meal, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of not being suitable for large-scale commercial production, not forming a stable large-scale supply, not forming a large-scale supply, etc., to improve amino acid Unbalanced problem, improving the feeding effect of bullfrog, promoting application and development prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Prepare low fishmeal bullfrog compound feed, method is as follows:

[0045] According to Table 1, the above various feed components (except soybean oil, fish oil, lysine, methionine, multi-dimensional and multi-mineral) are mixed in proportion, and are pulverized to about 98% through an 80 mesh sieve through a non-network ultrafine pulverizer. After adding lysine, methionine, multi-dimensional and multi-mineral, the material is mixed twice to ensure that the components of the material are uniform, and then enters the conditioner with saturated steam at 100-120°C for 100-150 seconds, and is extruded The puffing machine is processed to make puffed floating pellet feed, and the feed is dried by hot air until the water content is lower than 11%, and then soybean oil and fish oil are mixed according to the above ratio, and evenly sprayed on the surface of the pellet feed, and cooled to normal temperature to obtain the present invention low fishmeal bullfrog feed.

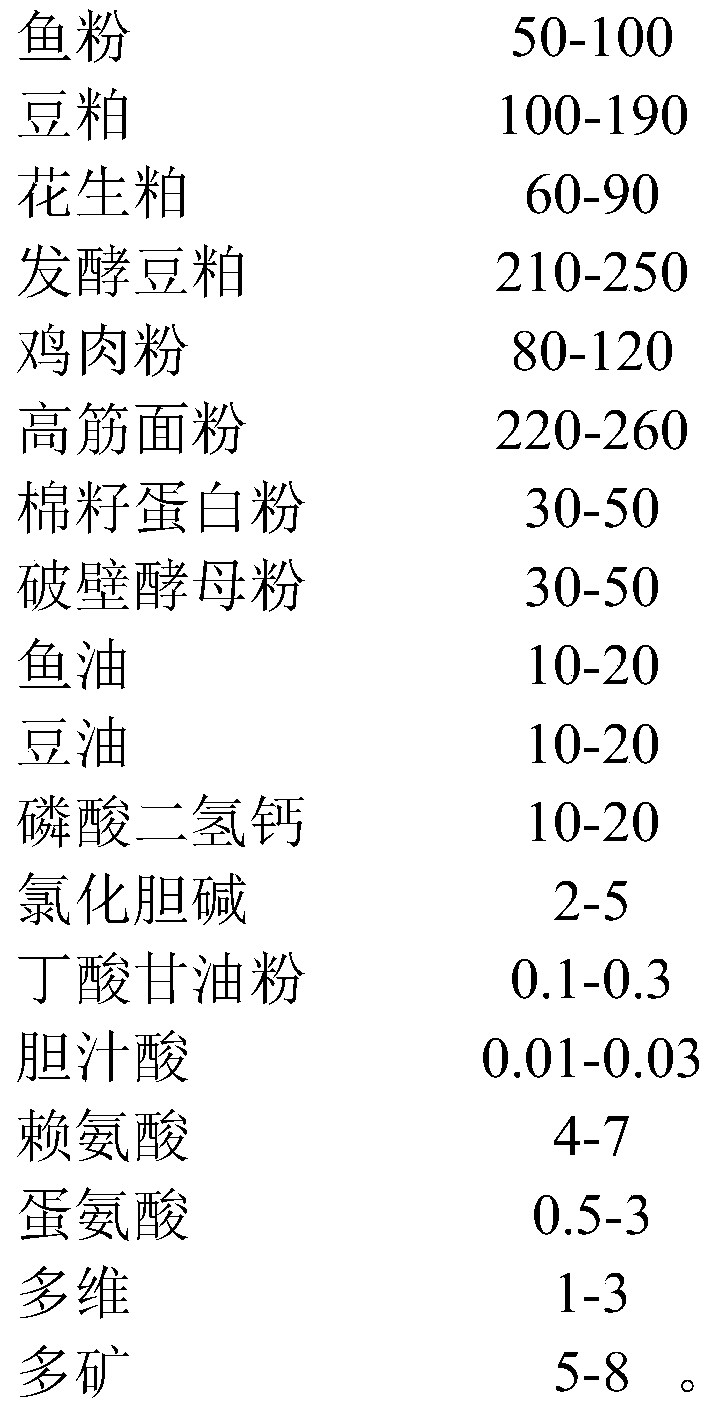

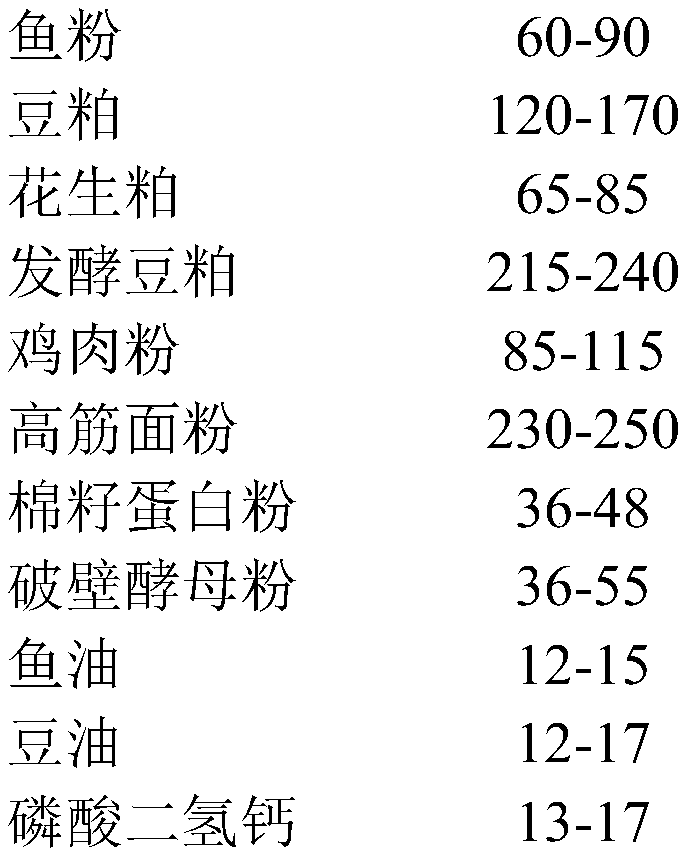

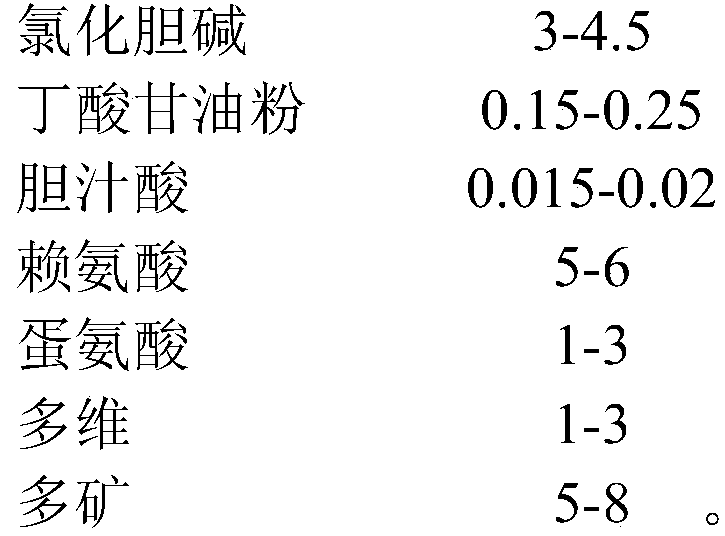

[0046] Tab...

Embodiment 2

[0049] The amount of raw materials is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0051] The amount of raw materials is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com