Patents

Literature

53results about How to "Improve delicious taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baking method for upper leaves of flue-cured tobacco

ActiveCN105942569APromote maturityReduce labor intensityTobacco preparationCooking & bakingChemical composition

The invention discloses a baking method for upper leaves of flue-cured tobacco. The baking method comprises the following steps: outbreak of a fire, a yellowing stage, a color fixing stage and a stem drying stage; and before baking, the material needs to be processed, including material collecting, tobacco weaving and tobacco filling. According to the invention, the baking condition of the upper leaves of the flue-cured tobacco can be controlled by controlling the heating rate and the temperature stabilizing time in baking, thus achieving an optimal effect. The baking method is capable of effectively reducing the labor strength in tobacco leaf harvest, promoting degradation and transformation of macromolecule substances in tobacco leaves, promoting the coordination of aroma substances and internal chemical components, improving aroma taste, reducing the ash hanging and stiffing proportion of upper leaves, and improving appearance quality.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

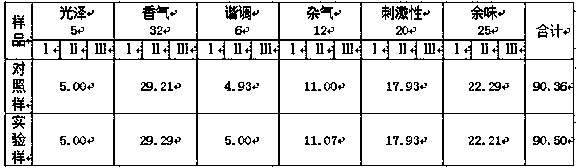

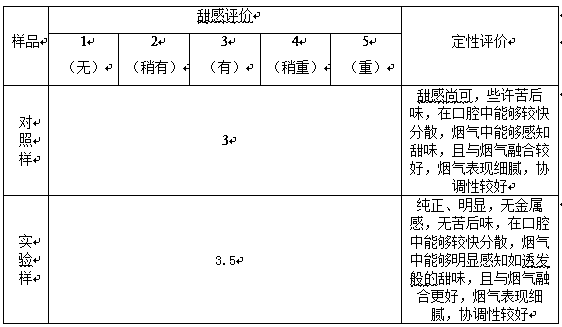

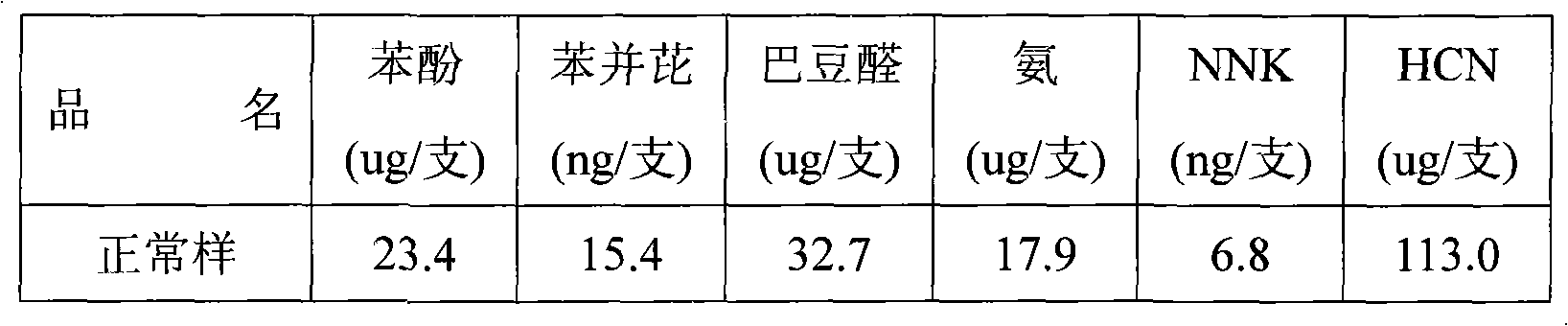

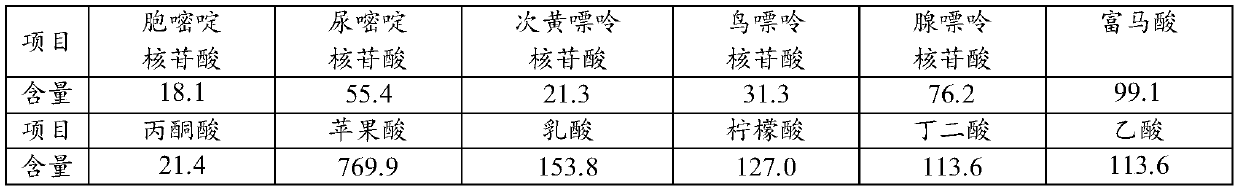

Manufacturing method of tipping paper with lasting positive sweetness and for cigarettes

ActiveCN111576092AImprove delicious tasteReduce dry mouthSpecial paperCigar manufactureSweet flavorProcess engineering

The invention discloses a manufacturing method of tipping paper with lasting positive sweetness and for cigarettes. The manufacturing method comprises the following specific steps: selecting materialsincluding a main sweetening agent, an acidity regulator, water, a sweetening aid and an ester additive, sequentially adding the above materials into a container according to a certain weight ratio, and carrying out uniform stirring to obtain a sweetening agent composition; sequentially adding ethanol, water, the sweetening agent composition and water-based ink into a container according to a certain weight ratio, and carrying out uniform stirring to obtain sweet gloss oil; then, with body paper as a processing object, preparing the sweet tipping paper for cigarette from the sweet gloss oil through three steps consisting of printing, gold stamping and slitting in sequence. The cigarette tipping paper is endowed with sweet taste; and after the cigarette tipping paper is connected with a cigarette in a rolling manner, a taste system of a smoker directly feels the positive sweet taste of the sweetening agent during smoking, so the dryness of the oral cavity of the smoker is reduced, and salivation promoting feeling is improved. According to investigation of the tipping paper after long-term storage, good stability of the sweet strength is still kept.

Owner:CHINA TOBACCO JIANGSU INDAL

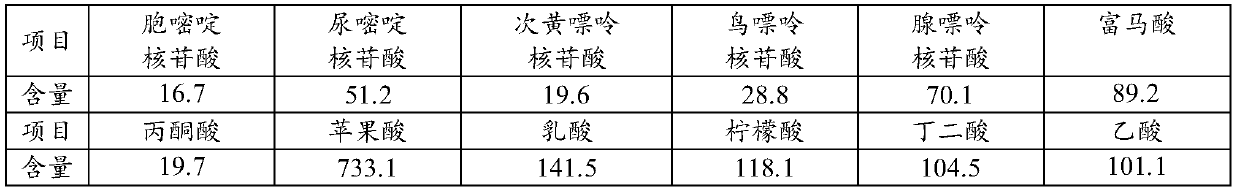

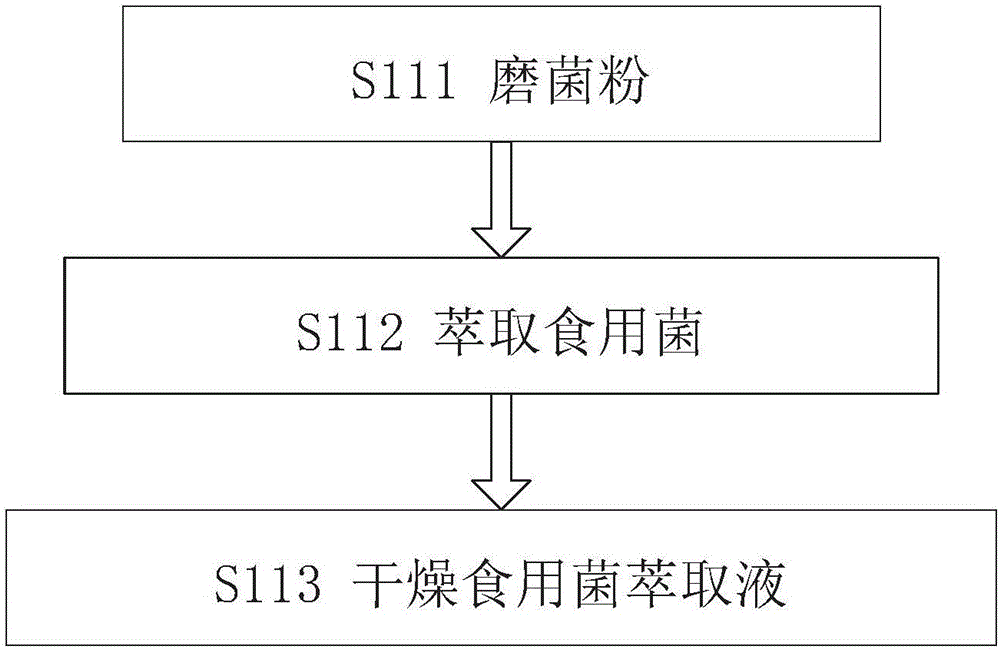

Method for extracting nutrient substances from edible mushrooms and application of nutrient substances of edible mushrooms in preparing seasoning

ActiveCN105146504AImprove delicious tasteImprove extraction efficiency and utilization efficiencyFood preparationNutrientStanding wave

The invention belongs to the technical field of deep food processing, particularly relates to a method for extracting nutrient substances of edible mushrooms and further discloses an application of the nutrient substances of the edible mushrooms in preparing seasoning. The method for extracting the nutrient substances of the edible mushrooms comprises the steps of enzymolysis pretreatment, ultrasound-assisted enzymolysis and enzyme deactivation. The optimal mode of ultrasound-assisted enzymolysis is discussed in detail, sine state ultrasonic waves of 40-50 kHz and 150-300 W and cosine state ultrasonic waves of 50-60 kHz and 150-300W are adopted for joint treatment, vibration amplitude can be increased through composite ultrasonic waves, and the mass transfer superficial area can be increased. Dead corners caused by standing waves can be reduced, and productivity can be improved. The maximum cavitation bubble of the composite ultrasonic waves is larger than that of combined ultrasonic waves, stronger breakdown is generated, and the better synergistic effect is achieved.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Tobacco waste recycling method

InactiveCN102125304ADoes not affect style characteristicsDoes not change draw qualityTobacco preparationTobacco smoke filtersCellulose acetateAdditive ingredient

The invention discloses a tobacco waste recycling method which is characterized by comprising the following steps of: by using tobacco particles, of 10-100 meshes, screened by a special cigarette producing apparatus, namely a tobacco shred drying machine, as the additive, uniformly adding the tobacco particles into a cigarette cellulose acetate tow in terms of 0.8 mg / mm to 3 mg / mm, and making the cellulose acetate tow into a base tow containing additive; making the base tow containing the additive and a common cellulose acetate tow into a composite filter tip; connecting the composite filter tip added with the tobacco particles on the body of a series of cigarette products of the same brand; and drying the filter tip and the cigarette body at the temperature of 20 to 60 DEG C for 1 to 8 hours in a closed environment. The tobacco waste recycling method improves the smell and taste of cigarette products of the same brand, and the aftertaste and comfortableness of cigarettes of the same brand, covers part of miscellaneous smokes, and improves the smoking quality of cigarettes. The cigarette products maintain the self tobacco fragrance, can be used as an effective absorbing material to absorb harmful smoke ingredients; and the tobacco waste recycling method disclosed by the invention is a good method for changing waste into wealth, and saving cost for cigarette enterprises.

Owner:YUNNAN RES INST OF TOBACCO SCI

Instant holothurian and preparation method thereof

ActiveCN101779805AImprove delicious tasteGuaranteed color and fragranceFood preparationPurified waterNutrient content

The invention relates to a method for preparing instant holothurian, comprising the steps of cleaning holothurian, cooking and packaging. The steps of cooking are sequentially as follows: cooking in water at 95+ / -2 DEG C according to the proportion of 1:3 of the holothurian to water ; instantly cooling the boiled holothurian to the normal temperature with purified water; immersing for 64-72 hours at 0-8 DEG C; and seasoning the holothurian by spice soup. The preparation method of the spice soup comprises the following steps of: uniformly adding auxiliary materials with 3-6% of starch in the purified water, stirring and dissolving uniformly, pouring the prepared mixed auxiliary materials in a jacketed kettle, heating slowly while stirring, wherein the pressure of steam is less than 0.2 mPa, heating while stirring rapidly, stopping heating when the temperature reaches 90 DEG C, keeping the temperature and stirring. The invention further relates to instant holothurian prepared by the method. The method for preparing the instant holothurian completely maintains the nutrient contents of live holothurian and fully improves good taste of the holothurian. The instant holothurian of the invention has nutrient contents, and can be eaten and stored conveniently.

Owner:ZHANGZIDAO GRP

Instant holothurian and preparation method thereof

ActiveCN101779804AImprove delicious tastePromote absorptionFood preparationAdditive ingredientPurified water

The invention relates to a method for preparing instant holothurian, comprising the following steps of: cleaning holothurian, putting into spice soup to shape and boiling for taste, preparing the spice soup, uniformly adding auxiliary materials in purified water, stirring to dissolve uniformly, pouring the auxiliary materials in a jacketed kettle, heating slowly while stirring, wherein the pressure of steam is less than 0.2 mPa, heating while stirring rapidly, stopping heating when the temperature reaches 90 DEG C, keeping warm and stirring; shaping with the proportion of 1:1 of the holothurian to the spice soup, at 55+ / -2 DEG C for 20-30 min; boiling for taste with the proportion of 1:1 of the holothurian to the spice soup, at 95+ / -2 DEG C for 50-60 min. The invention further relates to the instant holothurian prepared by the method. The method for preparing the instant holothurian completely maintains proper nourishment, increases the taste, fully improves good taste of the holothurian and promotes the absorption of the nutrient contents. The instant holothurian is convenient for a user to absorb the nutrient contents, and can be eaten and stored conveniently.

Owner:ZHANGZIDAO GRP

Mature-delay tobacco leaf baking process

The invention discloses a mature-delay tobacco leaf baking process, which relates to putting tobacco leaves in a baking barn and igniting. The process comprises the following steps: a, keeping dry-bulb temperature at 38 plus or minus 0.5 DEG C changelessly to roast for 4-6h; b, keeping the dry-bulb temperature at 40 plus or minus 0.5 DEG C changelessly to roast for 24-26h, keeping wet-bulb temperature at 39 plus or minus 0.5 DEG C within the first half of baking time, and keeping the wet-bulb temperature at 38 plus or minus 0.5 DEG C within the second half of baking time; c, keeping the dry-bulb temperature at 42 plus or minus 0.5 DEG C to roast for 26-28h; d, keeping the dry-bulb temperature at 44 plus or minus 0.5 DEG C to roast for 16-18h; e, keeping the dry-bulb temperature at 46 plusor minus 0.5 DEG C to roast for 14-16h; f, keeping the dry-bulb temperature at 48 plus or minus 0.5 DEG C to roast for 10-12h; g, keeping the dry-bulb temperature at 50 plus or minus 0.5 DEG C to roast for 8-10h; h, keeping the dry-bulb temperature at 54 plus or minus 0.5 DEG C to roast for 5-7h; i, keeping the dry-bulb temperature at 60 plus or minus 0.5 DEG C to roast for 7-9h; j, enabling the dry-bulb temperature to rise to 65-68 DEG C at the rate of heating up 1 DEG C every hour; keeping the dry-bulb temperature between 65 DEG C and 68 DEG C to roast for 19-21h; and finishing roasting.

Owner:陕西省烟草公司宝鸡市公司 +1

Fish balls and preparation method thereof

The invention relates to fish balls, which are characterized in that the fish balls are prepared from the following components: 30-45% of minced fillet, 5-8% of diced seafood, 2-5% of chicken bone juice, 0.5-1% of sesame paste, 2-4% of lentinus edodes, 0.5-1% of monosodium glutamate, 7-12% of starch, 1-2% of salt, 1-2% of white sugar, 0.5-1% of cooking wine, 2-4% of ginger juice, 2-5% of spice and the balance of vegetable pulp. Because diced seafood, chicken bone juice, sesame paste, ginger juice and the like are added in the raw materials, the delicious taste of the fish balls is improved, and the nutrition is richer. Because vegetable pulp is added, the fish balls have unique scent and fibrous tissue of vegetables, and are easy to be absorbed and digested.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Method for treating edible mushroom dry product, edible mushroom seasoning and preparation method of edible mushroom seasoning

InactiveCN110179104AMass productionEfficient removalFood ingredientsForeign matterEnzymatic hydrolysis

The invention provides a method for treating an edible mushroom dry product. According to the invention, an enzymatic hydrolysis technology is combined with a vacuum rolling method for the soaking ofedible mushroom dry products, large-scale production of the edible mushroom dry product processing industry can be met, the taste of the products can be effectively improved, and the delicious taste of the products can be increased. The soaking can be completed within 30-60 minutes, and the efficiency is obviously improved compared with traditional atmospheric water soaking which takes 3-6 hours.Vacuum rolling and vortex water cleaning is combined to effectively remove impurities of edible mushrooms and avoid foreign matter impurities in finished products, product quality is greatly improved,and thereby complaints are greatly reduced. No hot water is needed in the treatment process and water is saved greatly. Washing water is reused after impurities in the washing water are removed through a filtering device; the extruded water (rich in umami ingredients and polysaccharides) is concentrated to form mushroom extract, and no waste is generated. The method for soaking dried edible mushroom disclosed by the invention is suitable for soaking and infiltrating various dried materials, and has wide applicability.

Owner:NANYANG ZHANGZHONGJING SUPER KITCHEN

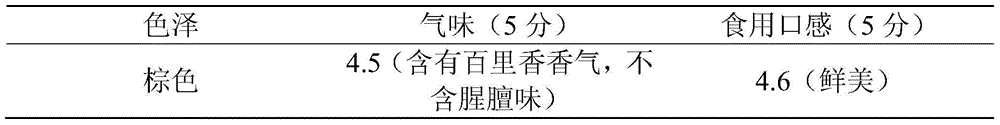

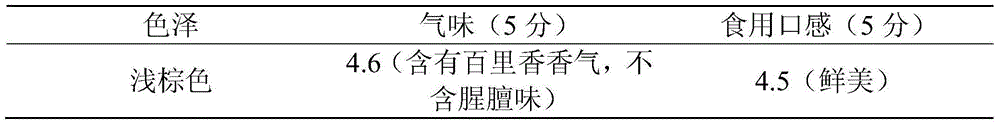

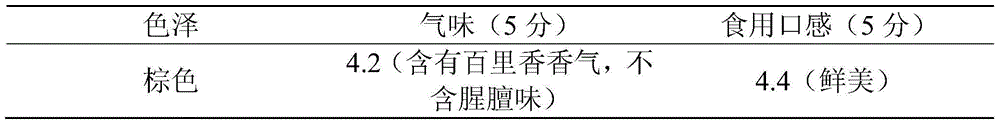

Preparation method of sauced pressed shredded ecological soft-shelled turtle

InactiveCN103535773AImprove delicious tasteImprove product added valueFood preparationCooking & bakingFlavor

The invention relates to a preparation method of a sauced pressed shredded ecological soft-shelled turtle. The method comprises the steps of material selecting, dissecting, preserving, air-drying, marinating with various different spices and auxiliary materials, hardening by baking and dehydrating by using a baking oven, vacuum packaging, sterilizing, paper box packaging, and storing. According to the invention, modern processes are sufficiently utilized, and ecological soft-shelled turtle is subjected to deep processing treatment. The process flow is reasonably designed, yield is high, and the process is clean. The prepared soft-shelled turtle has no odor, and has the flavor characteristics of sauced and pressed food. The soft-shelled turtle product provided by the invention is unique. According to the invention, soft-shelled turtle nutrients are perfectly preserved, and soft-shelled turtle delicious taste is enhanced. The finished product is easy to preserve. The soft-shelled turtle is an instant food, and is convenient to eat. Also, a novel processing technology is provided for industrialization, such that soft-shelled turtle product added value is improved, soft-shelled turtle product farmer income is increased, and aquaculture risk can be avoided.

Owner:汉寿县目平湖食品有限责任公司

Red vinasse flavored powder and preparation method thereof

InactiveCN104431933AImprove taste effectAvoid pollutionAcidic food ingredientsFood preparationFlavorSocial benefits

The invention provides red vinasse flavored powder and a preparation method thereof. According to the red vinasse flavored powder, fresh red vinasse is used as a raw material and red vinasse protein is degraded by an enzymolysis technology to obtain amino acid with a good flavor effect; and the red vinasse is dried and subjected to ultrafine crushing to obtain the red vinasse flavored powder. The red vinasse flavored powder processed by the invention integrates flavor, nutrition and functions; the commodity value and the economic additional value of the red vinasse are improved; the limitation that the red vinasse is used as a feed and is sold at low price or is directly used as wastes is broken through; and the red vinasse flavored powder has the practical significances on reduction of resource wastes and environmental pollution, and improvement on the economic benefits, the social benefits and the ecological benefits of Fujian yellow rice wine enterprises.

Owner:FUJIAN AGRI & FORESTRY UNIV

Delicious big millet and red grape zongzi wrapped by live oak leaves and corn leaves

InactiveCN103876051AGreat tasteHigh anticancer substancesFood preparationPolygonum fagopyrumBiotechnology

The invention discloses a delicious big millet and red grape zongzi wrapped by live oak leaves and corn leaves. A nutritional food wrapped by live oak leaves and corn leaves, provided by the invention, is characterized in that the live oak leaves and the corn leaves serve as an internal packaging material and an external packaging material respectively, and yellow millet, white sticky rice, gray bean, kidney bean, barley, buckwheat, oat, Chinese-date, semen coicis, Chinese yam, lily, and red grape which are soaked for 5 hours in advance according to a ratio are metered and packaged, and cooked to obtain the delicious big millet and red grape zongzi.

Owner:王新民

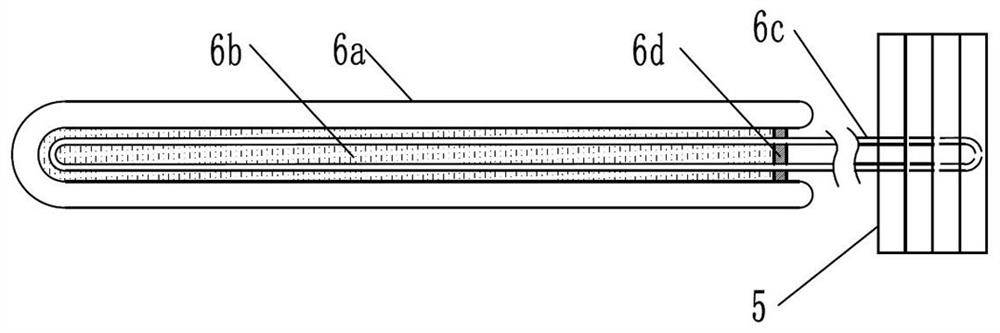

Method for preparing liquid molecules-embedded non-flammable perfuming material

ActiveCN105011361AIncrease delicious tasteIncrease retention efficiencyTobacco smoke filtersChemistryActivated carbon

The invention relates to a method for preparing a liquid molecules-embedded non-flammable perfuming material, which belongs to the cigarette technology field. The method provided by the invention adopts the porous structure of activated carbon materials to embed the molecules of liquid perfumes in the pores, so as to reduce the release speed. When a cigarette is smoked, the liquid perfume molecules are released under the dual function of heating and eluting of smoke aerosols, so as to improve the aroma and perfume of the cigarette smoke. The method provided by the invention has advantages that: the non-flammable section of the cigarette is effectively perfumed by the liquid perfume, the dosage of the essences and perfumes is saved, the cost can be controlled strictly, and the method is easy to be popularized and applied.

Owner:CHINA TOBACCO YUNNAN IND

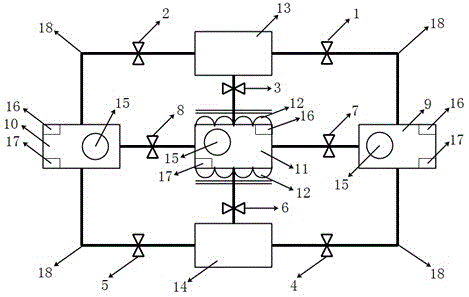

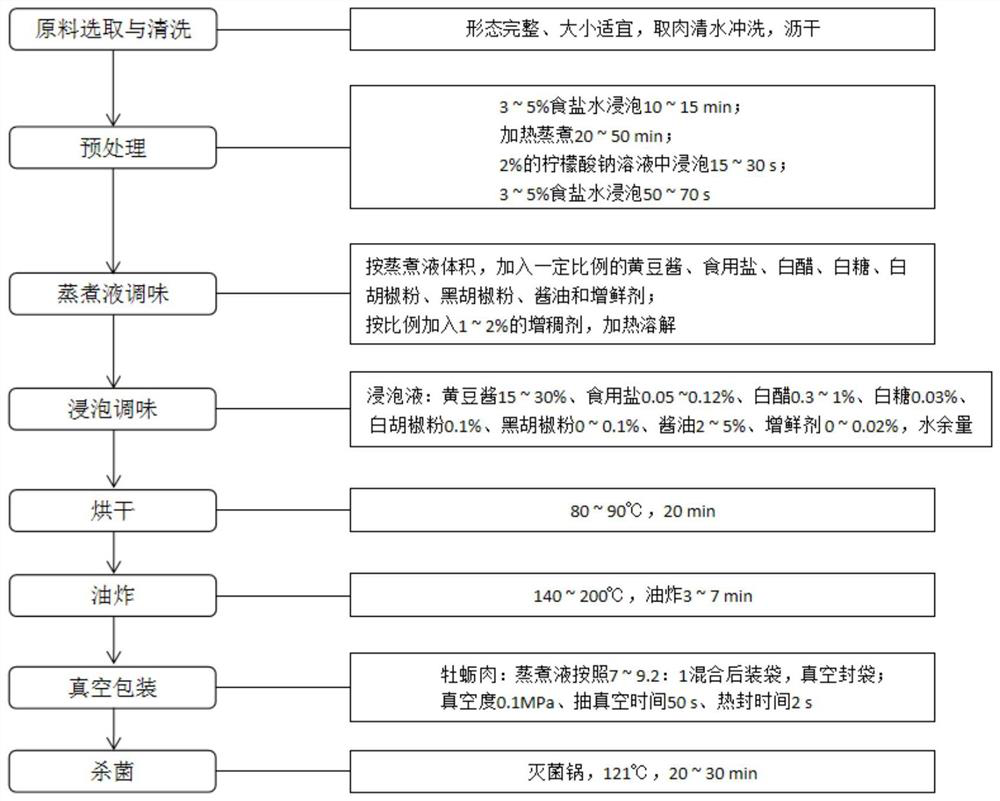

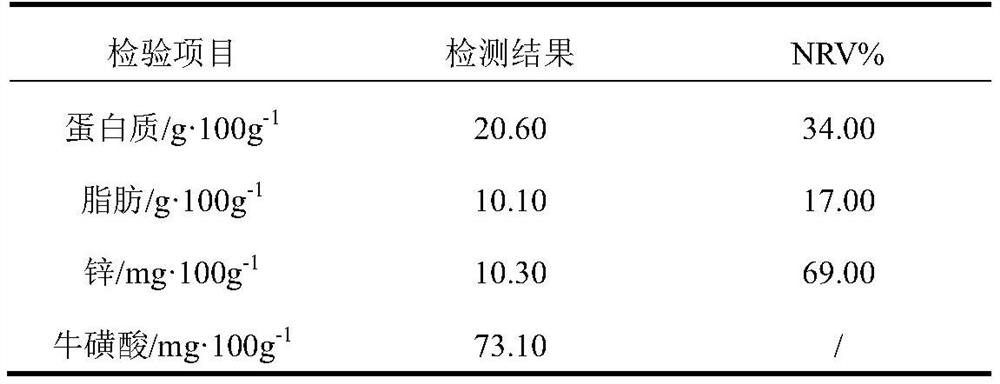

Preparation process of instant oyster soft can

ActiveCN111920021ADeliciousGreat tasteClimate change adaptationFood ingredient as taste affecting agentProcess engineeringVANILLA FLAVORING

The invention discloses a preparation process of an instant oyster soft can, and belongs to the technical field of food processing. The preparation process comprises the following steps: A1, selectingand cleaning raw materials; A2, performing pretreatment; A3, seasoning the cooking liquor; A4, performing soaking and seasoning; A5, performing drying; A6, performing deep-frying; A7, performing vacuum packaging; and A8, performing sterilization. The instant oyster soft can prepared by the method is golden in color and luster, has the unique fresh fragrance of fried oysters, and is proper in saltiness, rich in chewiness, rich in nutrition and suitable for being eaten by vast consumers.

Owner:FUJIAN NORMAL UNIV

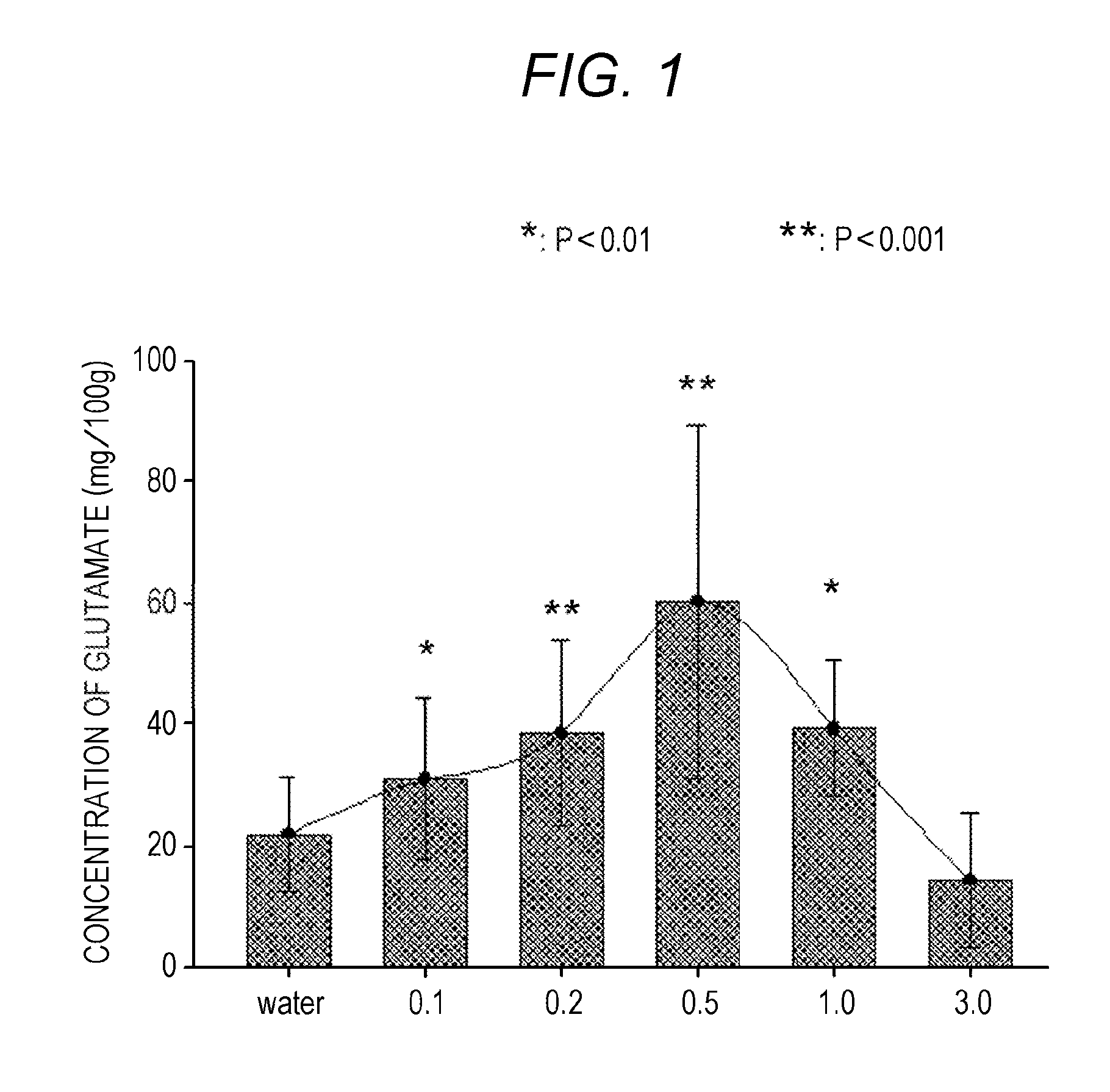

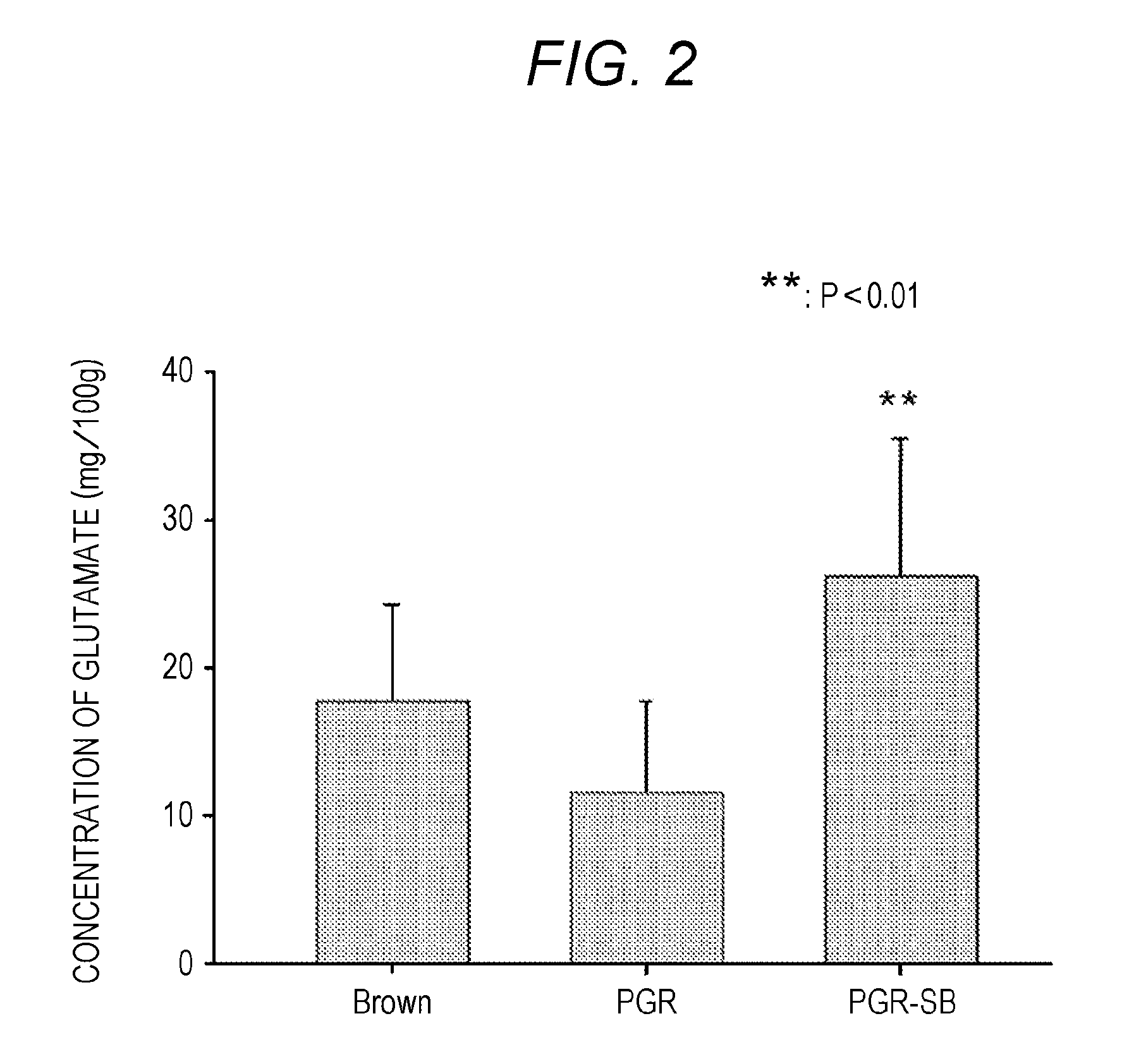

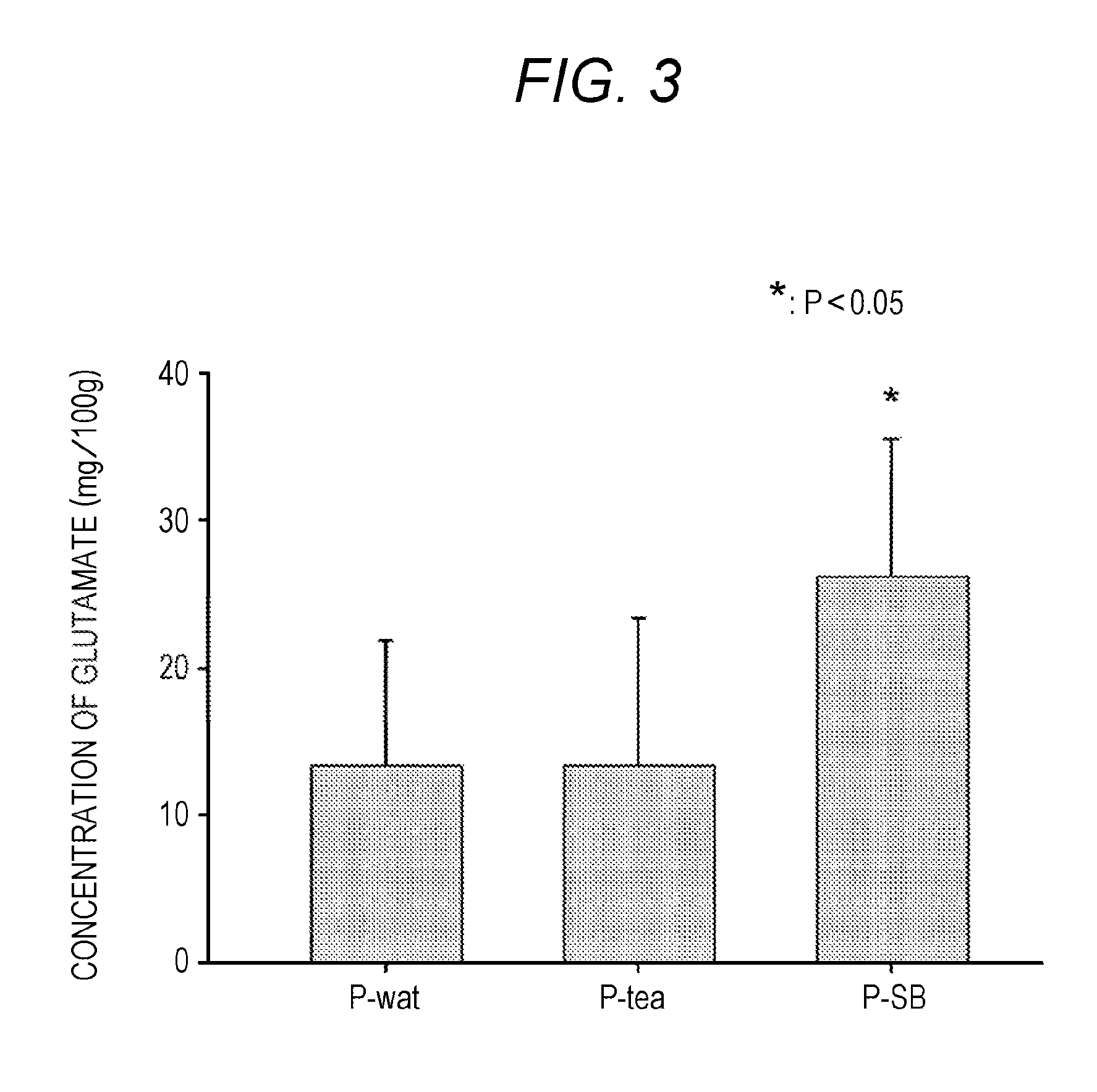

Sprouted cereal, method for manufacturing same, food product containing same, and bdnf production accelerator

ActiveUS20140065249A1Improve delicious tasteExcellent tasteBiocideNervous disorderFunctional foodGermination

The invention relates to a novel technique for germinating a sproutable food such as rice, other types of cereals, or seeds. Provided is a novel germination technique capable of increasing a content of glutamate, accelerating an enrichment of gamma-aminobutyric acid, and exerting excellent functionality for the body, and a novel functional food material or pharmaceutical agent. A sprouted cereal is produced by soaking the cereal in a soaking solution prepared by addition of at least one carbonate selected from alkali metal carbonate, and alkaline earth metal carbonate to water to make the cereal absorb the soaking solution, followed by allowing the cereal to germinate under predetermined conditions.

Owner:YANAMOTO HIROJI

Yeast extract soy sauce and preparation method thereof

PendingCN109007764AReduce usageReduce intakeFood ingredient functionsDark brown colorMonosodium glutamate

The invention discloses yeast extract soy sauce, which is prepared from 0.5 to 20 percent of yeast extracts, 3 to 15 percent of table salt, 0.5 to 5 percent of sweeting agents and the balance of water. In addition, the invention also provides a preparation method of the yeast extract soy sauce. The yeast extract soy sauce has the same appearance as conventional soy sauce and similar mouth feel; the taste is more delicious than that of conventional soy sauce; in addition, the yeast extracts are not genetically modified food and do not contain allergen ingredients such as soybean and wheat; fresheners such as monosodium glutamate and I+G are not added; food additives such as caramel pigments are not added; the yeast extract soy sauce can replace monosodium glutamate, and belongs to a pure natural and safe fresh taste substance. Meanwhile, the yeast extracts are combined with the table salt in the materials; the salty taste mouthfeel can be amplified; the consumption of thetable salt canbe reduced, so that the intake quantity of the table salt by people can be reduced. The yeast extracts through Maillard reaction have the natural dark brown color; the natural color can be provided for the seasoning juice for replacing the soy sauce. Meanwhile, the yeast extracts per se contain rich substances such as amino acid, peptide, polypeptide and nucleotide; the nutrition is rich.

Owner:大连珍奥生物技术股份有限公司

Preparation process of sauced and marinated duck product and sauced and marinated duck product

PendingCN112205588AImprove delicious tasteHigh nutritional valueClimate change adaptationFood scienceBiotechnologyUmami

The invention discloses a preparation process of a sauced and marinated duck product and the sauced and marinated duck product, and relates to the field of meat product processing. The preparation process of the sauced and marinated duck product comprises the following steps of S1, duck product pretreatment, S2, brine soup base boiling, S3, brine boiling, S4, duck product marinating and S5, sterilization and packaging. The sauced and marinated duck product has the effects of marinating to be tasty, being proper in taste, being lighter in fishy smell and being stronger in delicate flavor.

Owner:武汉精武人家食品工业园有限公司

Quick-frozen vegetable and fruit paste and preparation method thereof

The invention relates to the field of quick-frozen foods, in particular to quick-frozen vegetable and fruit paste and a preparation method thereof. The quick-frozen vegetable and fruit paste consistsof the following raw materials of 50-60 parts of a vegetable and fruit composition, 3-5 parts of parts of butter, 4-7 parts of unsalted butter, 20-30 parts of whole milk, 0.3-0.6 part of table salt, 0.5-2 parts of white granulated sugar, 5-15 parts of jam, 0-3 parts of bean granules, 0-3 parts of carrot granules, 0-3 parts of beef granules, and 0-3 parts of fish meat granules. Through a simple technology, the processed quick-frozen vegetable and fruit paste is high in nutrient value, and good in color, fragrance and taste.

Owner:HEBI SAIDE FOOD CO LTD +1

Production and processing method of shrimp brains and shrimp eggs

InactiveCN110338370AEasy to separateFast and efficient separation and collectionFood scienceSaline waterShrimp

The invention discloses a production and processing method of shrimp brains and shrimp eggs. The method includes the following steps that selected female shrimps are put into a water tank filled withice water for ultrasonic cleaning, the shrimp eggs in the abdomens of the female shrimps are separated and suspend in the ice water, and then the shrimp eggs can be collected by lifting a gauze net bag, and the shrimp heads of the female shrimps are separated, sent to a steam box for steaming and then naturally cooled; the shrimp brains are separated from the cooled shrimp heads, cleaned in cleanwater to remove left shrimp skin membranes and shrimp meat, then air-dried, frozen and packaged to obtain the shrimp brain products; the shrimp eggs are fried by using a frying pan and oven-dried to obtain the shrimp egg products. The method has the advantages that when the shrimp eggs are collected and processed, commonly discarded parts such as the shrimp brains are collected and deep processedto improve the economic benefits of the whole shrimps; the efficiency of shrimp egg collection is improved by using an ultrasonic cleaning and multi-layer distribution mode; the separation of the shrimp brains in the shrimp heads from other tissue is promoted by spraying alcohol-containing salt water before steaming, the preservation time of the shrimp brains is prolonged and the delicious taste is ensured.

Owner:江苏戚伍水产发展股份有限公司

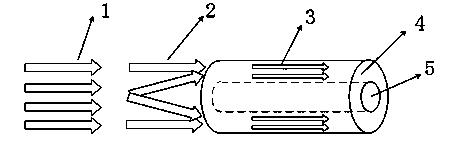

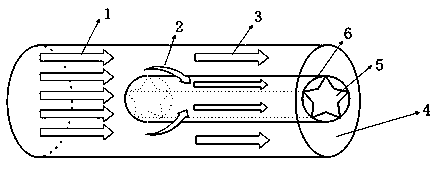

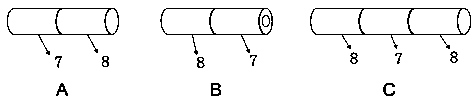

Cigarette filter tip with high interception efficiency and application

The invention relates to a cigarette filter tip with high interception efficiency and specific appearance. A segment of high-molecular polymer solid wire or cylinder with a certain size is added in a common filter stick. Before smoke enters the segment of the filter tip, due to obstruction of the solid wire or cylinder, smoke which is originally on the path of the solid wire or cylinder can move transversely and then enters surrounding tows or a cavity; therefore, the smoke is compressed, collision frequency of smoke aerosol molecules is increased, and the interception efficiency of the filter stick is greatly improved. A certain number of flavor and fragrance ingredients are added in the solid wire or cylinder and are released slowly when a smoker smokes cigarettes, and the amount of fragrance of the smoke is increased. The solid wire can be designed into combinations of different sections and forming paper, so that the diversity of the appearance of the filter tip is enhanced. The filter tip with the high interception efficiency is combined with a common filter tip to form the filter tip with different appearances, the recognition degree of the filter tip is improved, and the product differentiation is improved.

Owner:CHINA TOBACCO YUNNAN IND

Flavoring agent and preparation method thereof

InactiveCN104686980ATo achieve the purpose of removing mutton and increasing freshnessWide variety of sourcesFood preparationChemical additionMaterials science

The invention relates to a flavoring agent and a preparation method thereof. The flavoring agent comprises materials A and salt of which 1 g is added into 1 kg of the materials A, wherein the materials A comprise, by weight, the following components of mutton 65.5-67.5%, herbs powder 5.3-6.3%, cumin powder 1-1.2%, white radish powder 7.5-7.7%, starch 10.5-6%, coriander powder 1.2-1.4%, welsh onion powder 1.5-1.7%, ginger powder 1.3-1.4% and egg white 6.2-6.8%. After the mutton is minced, the egg white is sprayed on the mutton, and then the mutton and the egg white are mixed evenly; the herbs powder, the white radish powder, the coriander powder, the welsh onion powder, the ginger powder and the cumin powder are mixed evenly according to the proportion and then heated, and the flavoring agent is prepared. According to the flavoring agent and the preparation method thereof, the advantages of being exclusive in prescription and easy to prepare and the like is achieved, the prepared flavoring agent is free of smelling of fish or mutton and chemical addition agents, the cooking culture is enriched, and meanwhile the shelf life of the mutton is prolonged.

Owner:王立鹏

Instant holothurian and preparation method thereof

ActiveCN101779805BImprove delicious tasteGuaranteed color and fragranceFood preparationPurified waterNutrient content

The invention relates to a method for preparing instant holothurian, comprising the steps of cleaning holothurian, cooking and packaging. The steps of cooking are sequentially as follows: cooking in water at 95+ / -2 DEG C according to the proportion of 1:3 of the holothurian to water ; instantly cooling the boiled holothurian to the normal temperature with purified water; immersing for 64-72 hours at 0-8 DEG C; and seasoning the holothurian by spice soup. The preparation method of the spice soup comprises the following steps of: uniformly adding auxiliary materials with 3-6% of starch in the purified water, stirring and dissolving uniformly, pouring the prepared mixed auxiliary materials in a jacketed kettle, heating slowly while stirring, wherein the pressure of steam is less than 0.2 MPa, heating while stirring rapidly, stopping heating when the temperature reaches 90 DEG C, keeping the temperature and stirring. The invention further relates to instant holothurian prepared by the method. The method for preparing the instant holothurian completely maintains the nutrient contents of live holothurian and fully improves good taste of the holothurian. The instant holothurian of the invention has nutrient contents, and can be eaten and stored conveniently.

Owner:ZHANGZIDAO GRP

Edible fungus-flavor nutrition sausage and processing method thereof

The invention discloses an edible fungus-flavor nutrition sausage and a processing method thereof. The edible fungus-flavor nutrition sausage is prepared from 350-400 parts by weight of ass meat, 15-30 parts by weight of hericium erinaceus, 15-30 parts by weight of golden mushroom, 10-20 parts by weight of agrocybe cylindracea, 8-10 parts by weight of bamboo fungus, 30-60 parts by weight of soybean powder, 30-50 parts by weight of rice wine, 10-15 parts by weight of pawpaw powder, 2-3 parts by weight of flos puerariae, 2-3 parts by weight of pumpkin flower, 2-3 parts by weight of cherry leaf, 1-2 parts by weight of tangerine leaf, 2-5 parts by weight of purslane, 1-3 parts by weight of sunflower floral disc, 8-15 parts by weight of table salt, 10-20 parts by weight of camellia oil and 10-13 parts by weight of a food additive. The edible fungus-flavor nutrition sausage contains a plurality of domestic fungi, is rich in nutrients, improves a delicious taste, promotes digestion, has a fragrant, tender and tough taste and a unique local flavor, has a high health care value, has effects of invigorating spleen and tonifying liver, strengthening stomach and helping digestion, and clearing heat and removing toxins, can nourish internal organs, can improve body recovery functions and is beneficial for human body health.

Owner:何兵祥

Preparation method of quick-fried spicy sauce and spicy sauce

InactiveCN108402444AReasonable formulaRich in nutrientsFood ingredient functionsLean meatPreservative

The invention discloses a preparation method of quick-fried spicy sauce and the spicy sauce. The quick-fried spicy sauce comprises raw materials as follows: soybean oil, lean meat, dried mushrooms, dried chili, soybean paste, peanut kernels, sesame, onion, ginger, a seasoning mixture, white sugar, table salt and cooking wine. The preparation method of the quick-fried spicy sauce comprises the steps as follows: S1, preparation of raw materials; S2, pretreatment of dried mushrooms; S3, pretreatment of lean meat, dried chili, onion and ginger; and S4, quick-frying of all raw materials in soybeanoil, bottling of the quick-fried spicy sauce and sealing with caps. The spicy sauce has a reasonable formula, rich nutrient ingredients, no preservative and strong sauce aroma, has sauce and meat fused, is spicy and refreshing, easy to store, not prone to deterioration and suitable for people of all ages, can be used as cooking seasoning as well as food eaten together with rice or bread and has functions of promoting appetite and tonifying the spleen.

Owner:石梅

Colostrum Leken

InactiveCN109938104AImprove delicious tasteImprove human immunityMilk preparationOral mucosaWhey protein powder

The invention discloses a Colostrum Leken. The Colostrum Leken is prepared from, by weight, 10-20 parts of bovine colostrum powder, 10-15 parts of alpha-lactalbumin, 50-70 parts of sorbitol, 0.5-1 part of citric acid, 0.5-1.5 parts of strawberry essence, 0.5-1.5 parts of magnesium stearate, 1-4 parts of resistance dextrin and 0.1-0.5 part of concentrated vanilla. The Colostrum Leken adopts naturally-imported bovine colostrum and whey protein powder as raw materials, functional components of immune globulin and alpha-lactalbumin in the Colostrum Leken are extracted, the two immune proteins arecombined and prepared into the strawberry taste, and the delicious taste of the product is increased; through absorption of the mouth mucosa, an assimilation reaction of an immune system of the humanbody is started, a piece of Colostrum Leken is contained in the mouth anytime anywhere, and effects of enhancing the human immunity and preventing and relieving irritability are fundamentally achieved.

Owner:刘爱民

Instant holothurian and preparation method thereof

ActiveCN101779804BImprove delicious tastePromote absorptionFood preparationPurified waterNutrient content

Owner:ZHANGZIDAO GRP

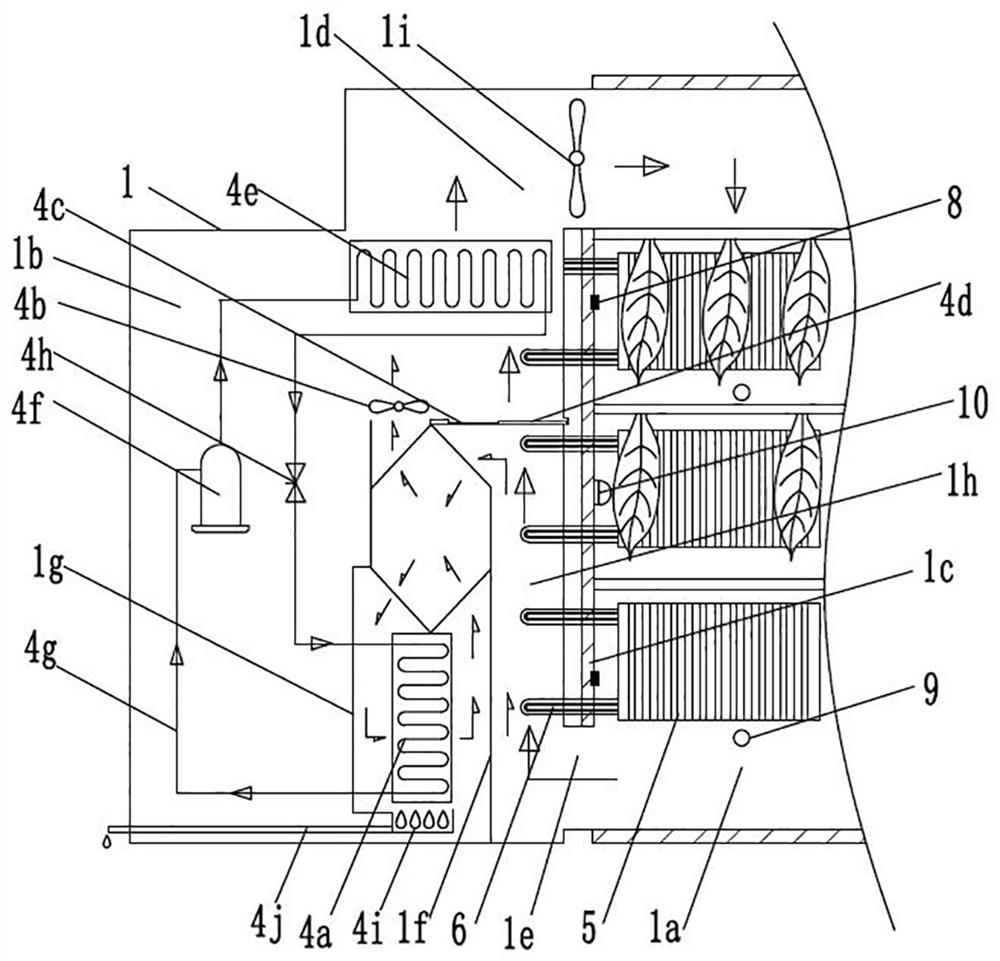

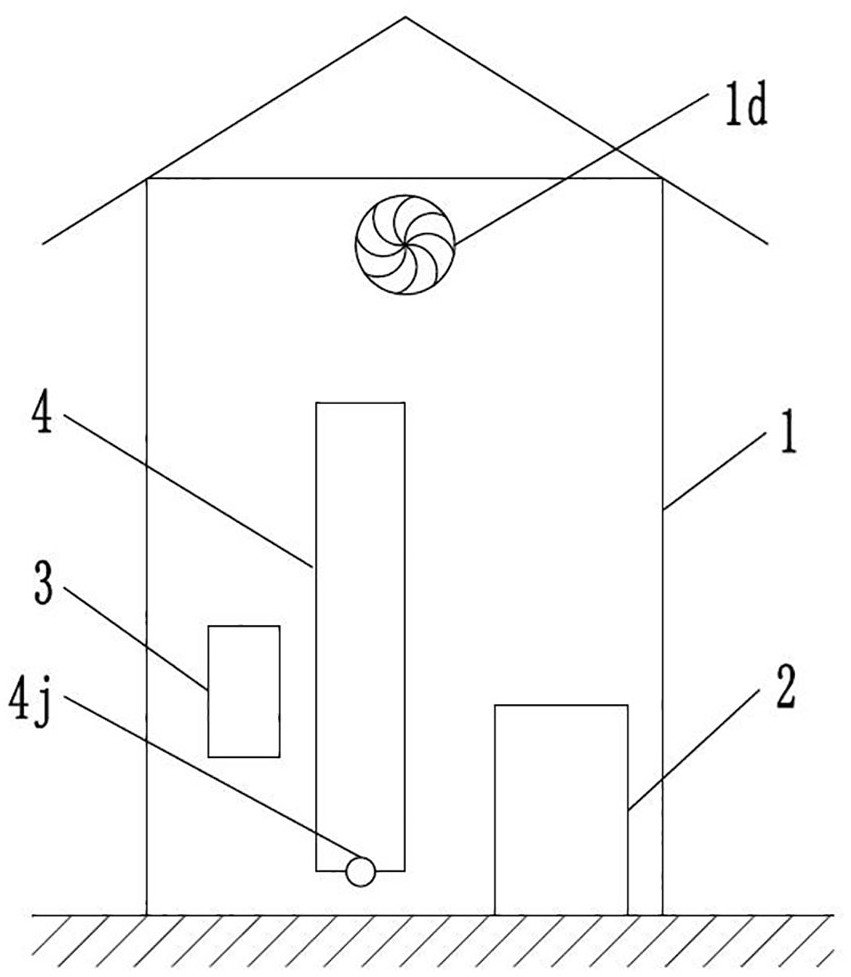

A frequency conversion flue-cured tobacco heat pump dual power barn

ActiveCN109330010BStable wind pressureStable air volumeTobacco preparationAutomatic controlThermodynamics

The invention discloses a frequency conversion flue-cured tobacco heat pump dual-power barn, which comprises a flue-cured tobacco room, a heating room, a heat pump unit, and a biomass fuel furnace. The return air outlet, the heating room is provided with a diversion wall facing the return air outlet, the heat pump evaporator of the heat pump unit is installed directly opposite the vent, the heat exchange device is installed above the heat pump evaporator, and the diversion fan is installed above the heat exchange device. The heat pump condenser of the heat pump unit is arranged at the air inlet, a biomass fuel furnace and a control device are arranged in the heating room, and a monitoring system connected to the control device is arranged in the flue-cured tobacco room. The present invention realizes automatic control through a control device, can precisely control temperature changes, and has high heat utilization efficiency. Compared with other curing methods, the curing cost is low and energy-saving, and the loss of tobacco leaf curing modulation is reduced, and the yellowing of tobacco leaves is coordinated with color fixing. Drying is matched with aroma, and the goal of roasting tobacco leaves to be yellow, dry and fragrant is achieved.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

A kind of red grain flavor powder and preparation method thereof

Owner:FUJIAN AGRI & FORESTRY UNIV

Making method of dendrobium stem and seahorse health-care soup

The invention discloses a making method of dendrobium stem and seahorse health-care soup, and belongs to the technical field of dendrobium stem processing. The making method comprises the following steps of (1) making dendrobium stem powder; (2) making seahorse powder; (3) adding the dendrobium stem powder and the seahorse powder into clean water, and performing cooking with a mild fire; (4) adding shiny-leaved yellowhorn and elm seeds, and performing cooking with a mild fire; and (5) filtering semi-finished products of the dendrobium stem and seahorse health-care soup with a gauze, so as to obtain the dendrobium stem and seahorse health-care soup. The dendrobium stem and seahorse health-care soup made by the method is fresh and delicious in taste and rich in nutrients, can sufficiently exert the health-care efficacy of dendrobium stems and seahorses, and has the effects of nourishing yin, nourishing the stomach, reinforcing the kidney, strengthening yang, conditioning blood and qi, conditioning stomach qi, enhancing immunity of human bodies and the like.

Owner:平南县德湖种养农民专业合作社

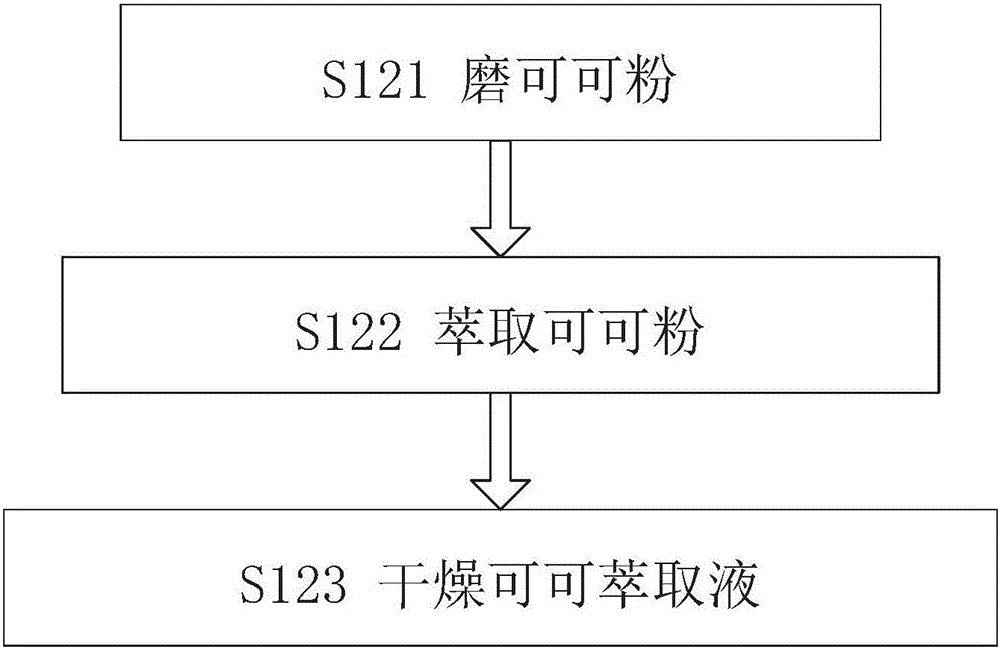

Solid chocolate beverage and preparation method thereof

InactiveCN106666018AGreat tasteGrowth inhibitionCocoaNatural extract food ingredientsSucroseTremella

The invention discloses a solid beverage and a preparation method thereof and especially relates to a solid chocolate beverage and the preparation method thereof. The solid chocolate beverage comprises an edible mushroom extract and a cocoa extract, wherein the mass of the edible mushroom extract is 20%-80% of the total mass; the mass of the cocoa extract is 80%-20% of the total mass; and the edible mushroom extract is selected from at least one of pleurotus nebrodensis extract, maitake mushroom extract and tremella extract. The cane sugar is replaced by the edible mushroom extract, so that the beverage taste is improved, and meanwhile, the body burden is not increased, and one or more of the pleurotus nebrodensis extract, the maitake mushroom extract and the tremella extract can be randomly selected and mixed according to different tastes and the required drinking effect.

Owner:范苑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com