Tobacco waste recycling method

A technology for waste materials and tobacco, which is applied in the field of recycling and utilization of waste tobacco materials, can solve the problems of low yield and other problems, and achieve the effects of enhancing the amount of aroma, improving aftertaste and comfort, and maintaining consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

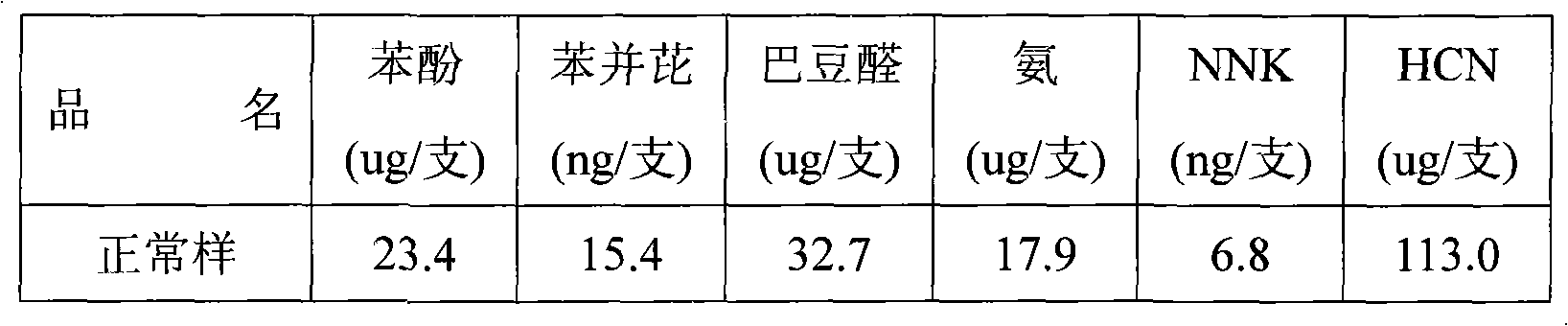

Embodiment 1

[0015] Collect the fine and uniform tobacco particles (P1) of a certain brand of cigarettes that are screened out during the production process of the special tobacco production equipment "shred dryer" and stored in the screening storage cabinet at the lower part of the tobacco special production equipment "shred dryer", and screened For 40-60 mesh particles, measure the void structure parameters such as the specific surface area (results are shown in Table 1). Use the special tobacco production equipment mouth stick production unit to evenly add tobacco particles to the cigarette acetate fiber mouth stick at 1.7mg / mm to make a basic stick with added materials, and then use the tobacco special production equipment mouth stick composite molding machine to The basic tip stick with added materials and the ordinary acetate tip stick are made into a composite filter. The composite filter rod with tobacco particles added is connected to the same cigarette product tobacco rod with no...

Embodiment 2

[0020] Collect the fine and uniform tobacco particles (P2) of a certain brand of cigarettes that are screened out during the production process of the special tobacco production equipment "shred dryer" and stored in the screening storage cabinet at the lower part of the special tobacco production equipment "shred dryer", and screened The 20-30 mesh particles are sprayed with flavor and fragrance at 1 / 3 of the brand’s conventional flavoring amount, and placed in a sealed room at room temperature (25°C) for 4 hours for later use. The specific surface and other void structure parameters are measured (results are shown in Table 1). Use the special tobacco production equipment mouth stick production unit to evenly add tobacco particles to the cigarette acetate fiber mouth stick at a rate of 1.25mg / mm to make a basic stick with added materials, and then use the tobacco special production equipment mouth stick compound molding machine to The basic tip stick with added materials and th...

Embodiment 3

[0023] Collect the fine and uniform tobacco particles (P3) of a certain brand of cigarettes that are screened out during the production process of the special tobacco production equipment "shred dryer" and stored in the screening storage cabinet at the lower part of the special tobacco production equipment "shred dryer", and screened The 70-90 mesh particles are sprayed with flavors and fragrances with 1 / 4 of the conventional flavoring amount of the brand, and placed in an airtight place at room temperature (25°C) for 4 hours for later use, and the specific surface and other void structure parameters are measured (results are shown in Table 1). Use the tobacco special production equipment mouth stick production unit to evenly add tobacco particles to the cigarette acetate fiber mouth stick at a rate of 2.5mg / mm to make a basic stick with added materials, and then use the tobacco special production equipment mouth stick composite molding machine to The basic tip stick with added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com