Preparation process of instant oyster soft can

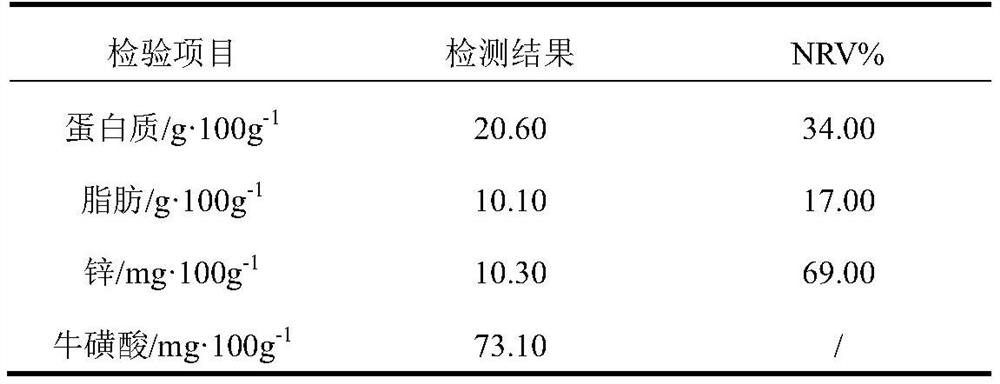

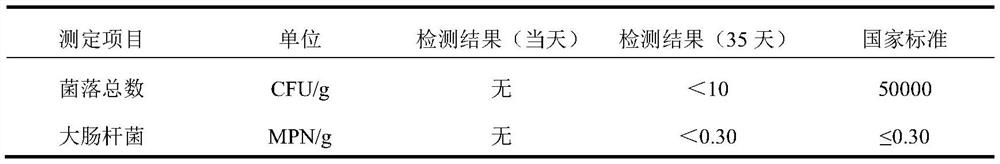

A preparation process and a technology for soft canned food are applied in the directions of food science, food ingredients as taste modifiers, food ingredients as odor modifiers, etc., and can solve the problems of poor taste of oysters, poor taste of canned oysters, low purine content and the like, To achieve the effect of improving delicious taste, good taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

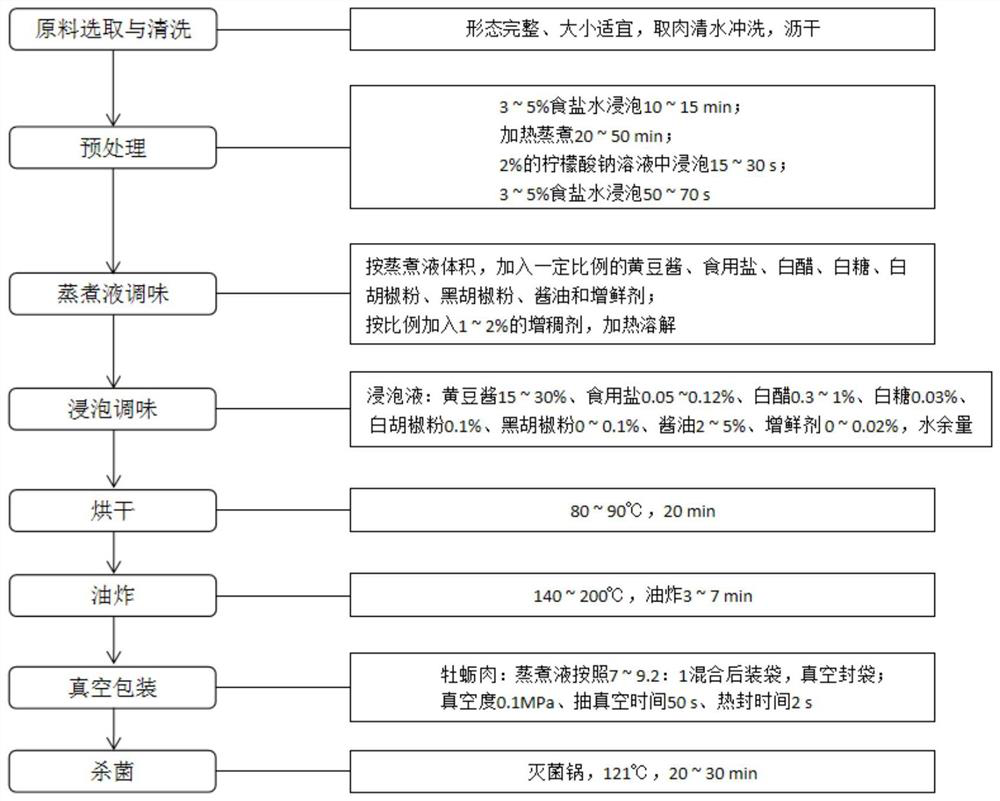

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation technology of ready-to-eat oyster soft can, it is characterized in that: comprise the steps:

[0035] A1. Raw material selection and cleaning: select oysters with complete shape and suitable size, dig out the oyster meat and rinse with clean water to remove sediment and impurities, and drain the water for later use;

[0036] A2. Pretreatment: Soak the cleaned oyster meat in 5% salt water and take it out for 10 minutes; put the drained oyster meat into clear water and cook it for 30 minutes, and keep the cooking liquid for later use; The cooked oyster meat is soaked in 2% sodium citrate solution by mass percentage, taken out after 20s and drained, put into 5% saline solution for 60s, then taken out, and drained for later use;

[0037] A3. Cooking liquid seasoning: Add seasoning to the cooking liquid for initial seasoning. The seasoning is calculated according to the volume of the cooking liquid, including the following components: 20% soybean paste,...

Embodiment 2

[0046] A kind of preparation technology of instant oyster soft can, comprises the steps:

[0047] A1. Raw material selection and cleaning: select oysters with complete shape and suitable size, dig out the oyster meat and rinse with clean water to remove sediment and impurities, and drain the water for later use;

[0048] A2, pretreatment: put the cleaned oyster meat in 3% saline solution for 10 minutes and take it out; put the drained oyster meat into clear water, heat and cook for 20 minutes, and then take it out, and the cooking liquid is for later use; Put the oyster meat into 2% sodium citrate solution by mass and soak it for 15s, take it out and drain it, put it into 3% salt water again and soak it for 50s, take it out, drain it for later use;

[0049] A3. Cooking liquid seasoning: Add seasonings to the cooking liquid for initial seasoning. The seasonings are calculated according to the volume of the cooking liquid, including the following components: 15% soybean paste, 0...

Embodiment 3

[0058] A kind of preparation technology of instant oyster soft can, comprises the steps:

[0059] A1. Raw material selection and cleaning: select oysters with complete shape and suitable size, dig out the oyster meat and rinse with clean water to remove sediment and impurities, and drain the water for later use;

[0060] A2, pretreatment: put the cleaned oyster meat in 5% salt water and soak it for 15 minutes and take it out; put the drained oyster meat in clear water and heat and cook for 50 minutes and then take it out, and the cooking liquid is for subsequent use; Soak the oyster meat in a 2% sodium citrate solution by mass for 30 seconds, take it out and drain it, put it in 5% saline solution for 70 seconds, remove it, and drain it for later use;

[0061] A3. Cooking liquid seasoning: add seasoning to the cooking liquid for initial seasoning. The seasoning is calculated according to the volume of the cooking liquid, including the following components: 25% soybean paste, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com