Flavoring agent and preparation method thereof

A production method and technology of seasoning agent, which are applied in the field of seasoning, can solve the problems of mutton mutton and neglect, and achieve the effects of pure taste, simple production and physical enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

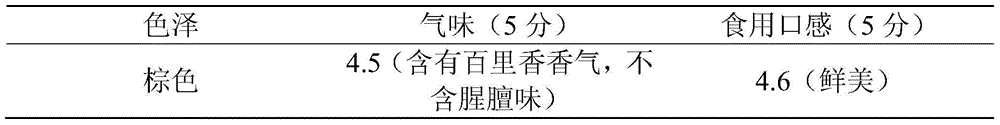

Embodiment 1

[0032] 1) prepare 1kg of material A, by weight percentage, wherein fresh mutton accounts for 65.5%, thyme 5.3%, cumin 1%, white radish 7.5%, starch 10.5%, coriander 1.2%, green onion 1.5%, ginger 1.3% and egg Clear 6.2%; And add the salt of 1g by every 1kg above-mentioned material A.

[0033] 2) Process the selected raw materials according to the following process steps:

[0034] ①. Wash and mince the fresh mutton, pass through a 70-mesh sieve, pour the prepared egg white, and stir evenly to obtain mutton egg slurry;

[0035] ②. Wash and finely chop thyme, white radish, coriander, green onion and ginger, respectively, and heat them together with cumin at 50°C for 6 hours until dried, crushed and finely ground, and passed through a 70-mesh sieve to obtain thyme powder, white radish powder, Coriander powder, onion powder, ginger powder and cumin powder;

[0036] ③. Quantitatively mix the materials obtained in step ① and step ② according to the proportion, add salt and mix well...

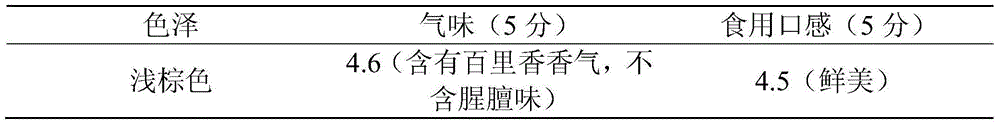

Embodiment 2

[0045] 1) prepare 1kg of material A, by weight percentage, wherein fresh mutton accounts for 66.5%, thyme 5.8%, cumin 1.1%, white radish 7.6%, starch 8.3%, parsley 1.3%, green onion 1.6%, ginger 1.3% and egg Clear 6.5%; And add the salt of 1g by every 1kg above-mentioned material A.

[0046] 2) Process the selected raw materials according to the following process steps:

[0047] ①. Wash and mince the fresh mutton, pass it through a 75-mesh sieve, pour the prepared egg white, and stir evenly to obtain mutton egg slurry;

[0048] ②. Wash and finely chop thyme, white radish, coriander, green onion, and ginger respectively, and keep them together with cumin at 80°C for 5 hours until dried, crushed, and finely ground. Pass through a 75-mesh sieve to obtain thyme powder, white radish powder, Coriander powder, onion powder, ginger powder and cumin powder;

[0049]③. Quantitatively mix the materials obtained in step ① and step ② according to the proportion, add salt and mix well to ...

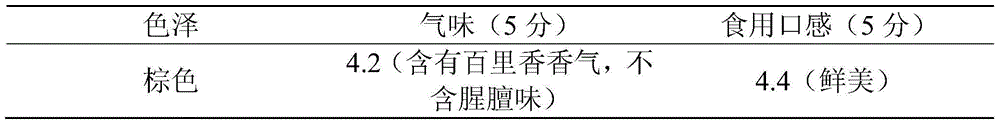

Embodiment 3

[0057] 1) prepare 1kg of material A, by weight percentage, wherein fresh mutton accounts for 67.5%, thyme 6.3%, cumin 1.2%, white radish 7.7%, starch 6%, coriander 1.4%, green onion 1.7%, ginger 1.4% and egg Clear 6.8%; And add the salt of 1g by every 1kg above-mentioned material A.

[0058] 2) Process the selected raw materials according to the following process steps:

[0059] ①. Clean and mince the fresh mutton, pass it through a 80-mesh sieve, pour the prepared egg white, and stir evenly to obtain mutton egg slurry;

[0060] ②. Wash and finely chop thyme, white radish, coriander, green onion, and ginger, respectively, and heat them together with cumin at 100°C for 4 hours until dried, crushed, and finely ground. Pass through a 80-mesh sieve to obtain thyme powder, white radish powder, Coriander powder, onion powder, ginger powder and cumin powder;

[0061] ③. Quantitatively mix the materials obtained in step ① and step ② according to the proportion, add salt and mix well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com