Refractory material processing device

A processing device and refractory material technology, applied in the field of refractory material processing, can solve the problems of reducing the stirring pressure of stirring components, forming hardening, etc., and achieve the effects of improving utilization rate, prolonging service life, and improving material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

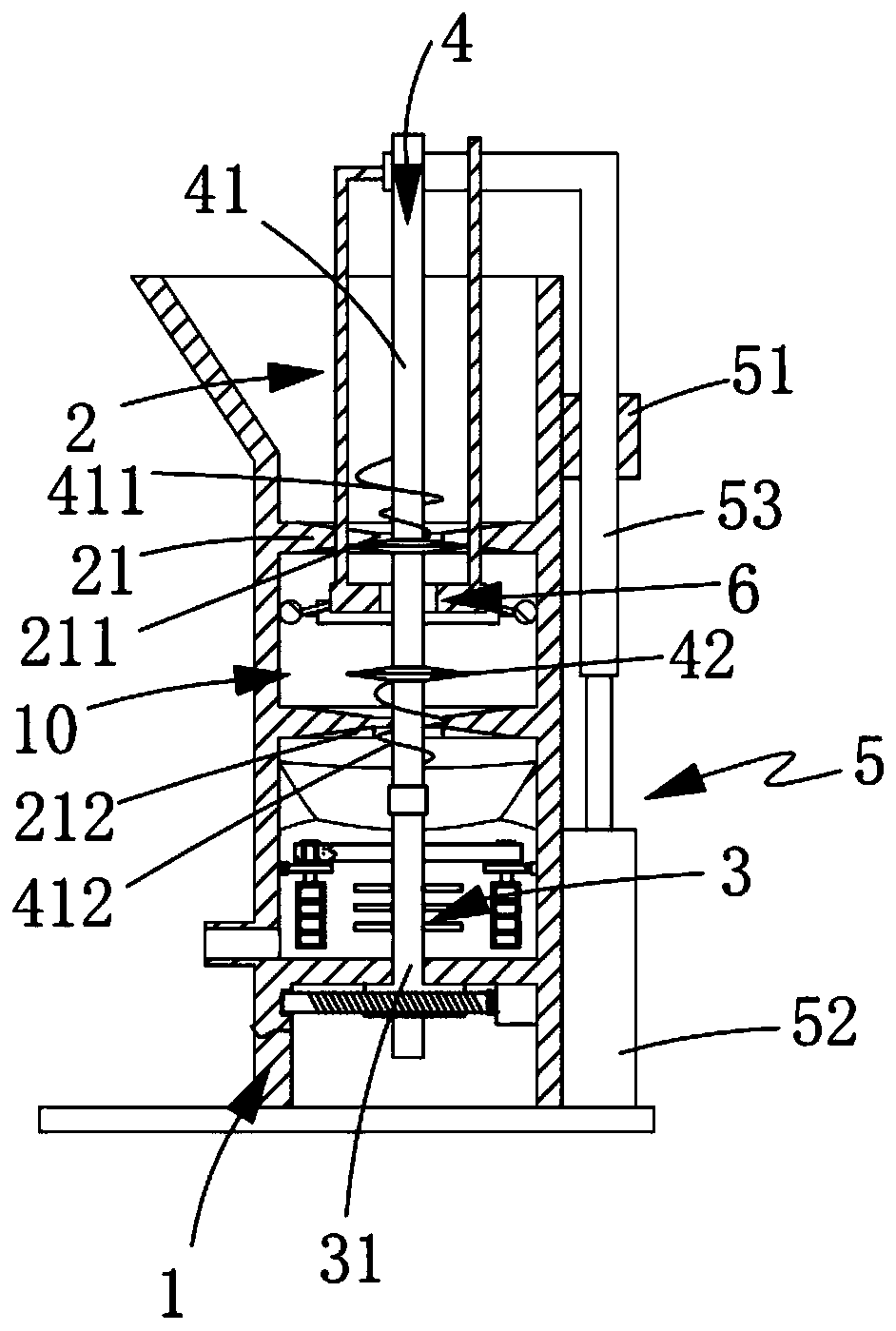

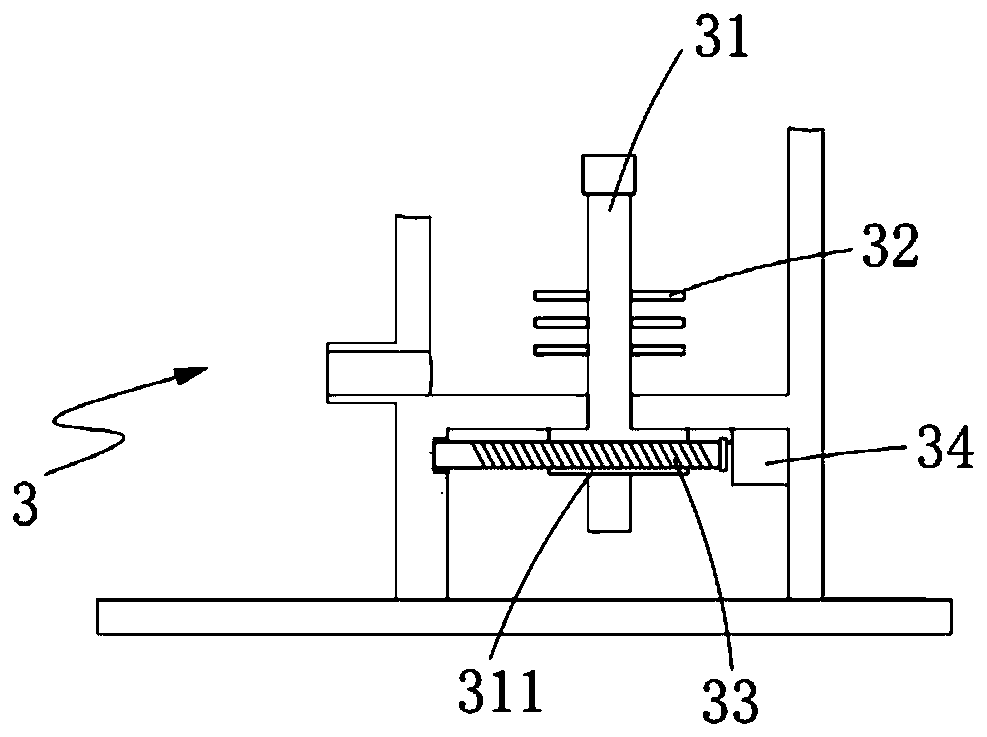

[0048] Such as figure 1 , 3 As shown in and 4, a refractory material processing device includes a circular base 1 and a box body 2, the box body 2 is arranged on the circular base 1, and the box body 2 is provided with a The partition 21, the two partitions 21 are set up and down to form a material storage space 10, the middle part of the partition 21 is provided with a through hole 211, and its two ends are provided with leakage grooves 212, which also includes:

[0049] A stirring assembly 3, the stirring assembly 3 is installed in the circular base 1;

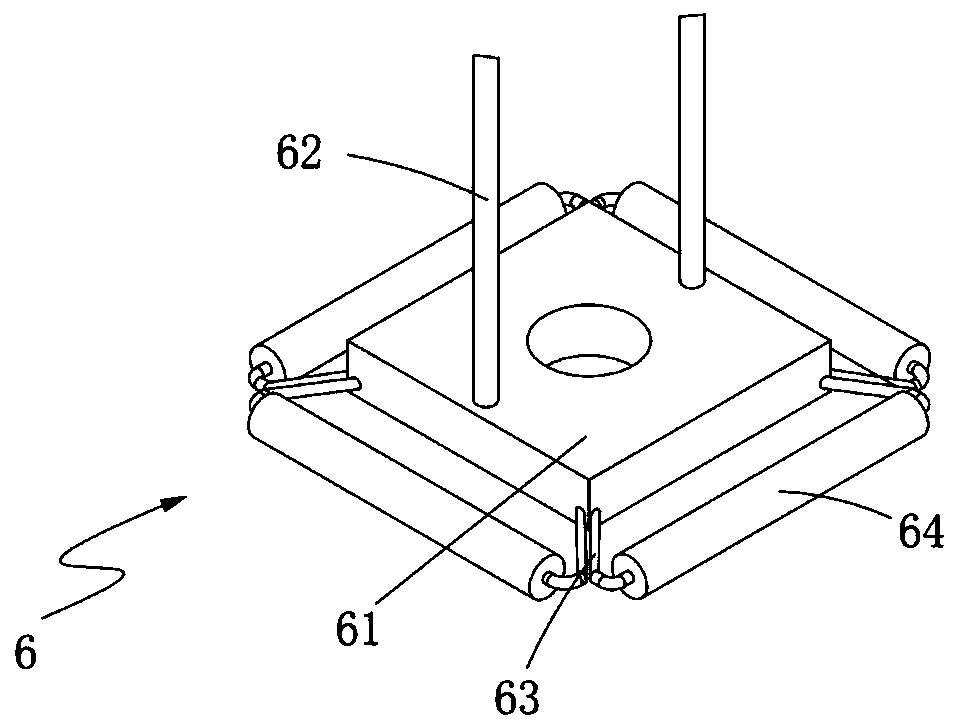

[0050]The feeding assembly 4, which is installed in the box body 2, includes a vertically arranged rotating shaft 41 and a blocking plate 42 arranged on the rotating shaft 41, and the rotating shaft 41 is connected to the The through hole 211 is coaxially arranged, the rotating shaft 41 is driven to rotate by the stirring assembly 3, the blocking material disc 42 is located in the material storage space 10, and the two blo...

Embodiment 2

[0070] Figure 5 and Figure 6 It is a structural schematic diagram of Embodiment 2 of a refractory material processing device of the present invention; as Figure 5 and 6 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0071] Such as Figure 5 and 6 As shown, the stirring assembly 3 also includes:

[0072] A first crossbar 35, the first crossbar 35 is arranged on the first rotating rod 31 in a horizontal direction;

[0073] The second rotating rod 36, the two second rotating rods 36 are respectively rotated and arranged at both ends of the first cross bar 35, and they are arranged parallel to the first rotating rod 36;

[0074] The gear 37, the gear 37 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com