System and method for neutralizing and recovering aluminum hydroxide and sodium sulfate in oxidizing liquid and potting liquid

A technology of aluminum hydroxide and recovery system, which is applied in the field of aluminum processing, and can solve problems such as increasing processing costs, losing the original intention of alkali recovery design, and hindering the implementation of patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] Embodiment 1 (decomposition law of dissolving aluminum in pot mold liquid)

[0155] According to different alkali concentrations, one liter tank is opened to dissolve aluminum chips, and the change law of free alkali concentration, aluminum ion concentration and bath solution decomposition is studied. After dissolving the aluminum chips each time, stir evenly, replenish the liquid level to one liter, precipitate, titrate the concentration of free alkali and aluminum ion, the results are shown in Table 1 (J is the concentration of free alkali in g / L, and L is the concentration of aluminum ion in g / L, R is free alkali concentration / aluminum ion concentration), obtains following experimental result:

[0156] 1) The decomposition point of sodium metaaluminate in the potting liquid is R=3.00, around R=3.00, the potting liquid starts to decompose, and aluminum hydroxide is precipitated;

[0157] 2) Under the condition that there is no external seed crystal, the transportati...

Embodiment 2

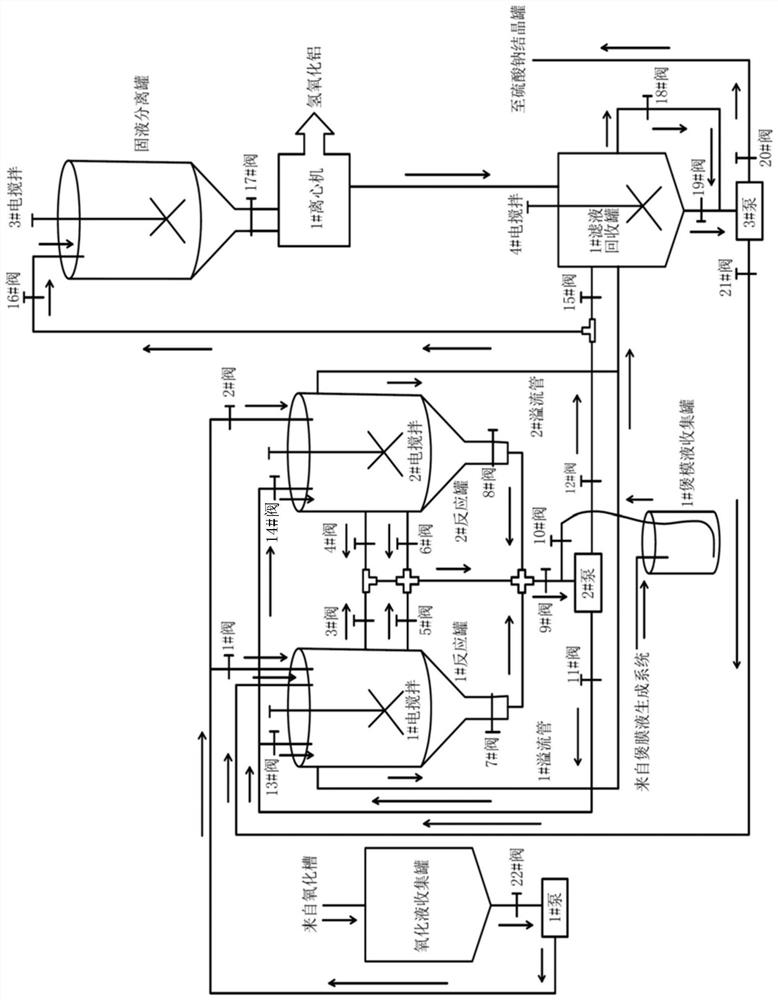

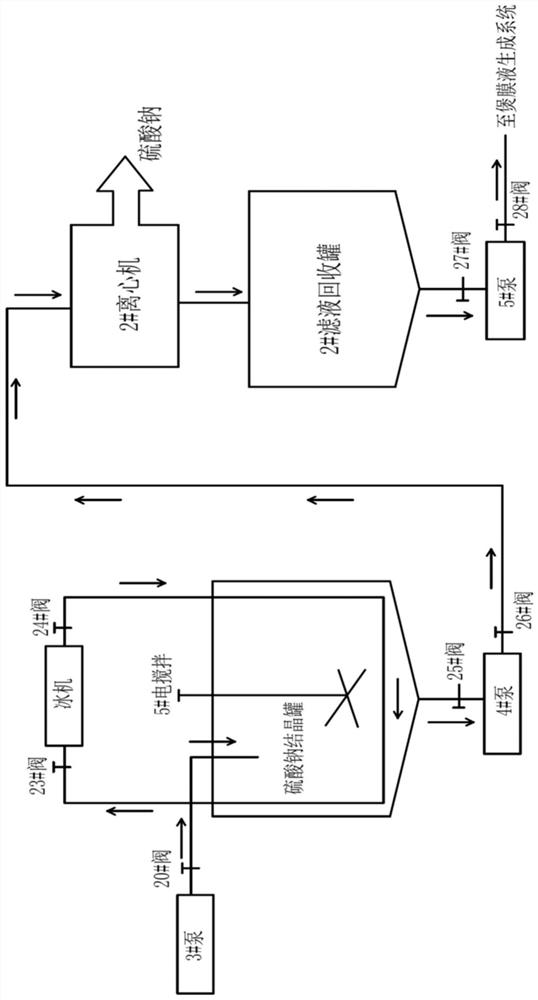

[0159] Embodiment 2 (add pot liquid to reclaim aluminum hydroxide and sodium sulfate in oxidation waste liquid)

[0160] Take 2.951 liters of oxidation waste liquid (total acid 200g / L, aluminum ion 20 / L), add potting liquid (J253.33L51.35R4.93), one liter to the end of the reaction, pH between 7.00-7.50, metaaluminate Sodium separation and separation; filtering, rinsing, and drying to obtain high-purity aluminum hydroxide products that meet the requirements of the national standard; cooling the filtrate once to below 5°C, using the physical characteristics of sodium sulfate's sharply reduced solubility at low temperatures, crystallization of sodium sulfate, Solid-liquid separation, rinsing, and drying to obtain sodium sulfate products; the secondary filtrate is sent back to the mold groove to continue the mold, realizing zero discharge of waste water and residue from the mold; the recovery of sodium ions completely realizes the isolation of sodium ions from the waste water cent...

Embodiment 3

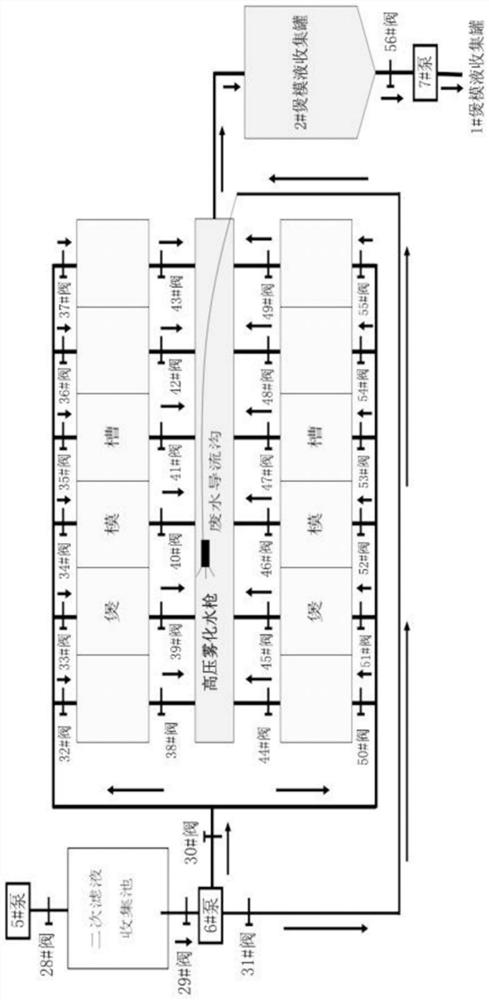

[0161] Embodiment 3 (pot mold liquid generation system operation)

[0162] Such as figure 1 As shown, the operation of the pot mold liquid generation system: close each inlet and outlet valve of the pot mold groove, open the 29# valve, 30# valve and 6# pump, and fill the pot mold groove with water; press 150-250g / L sodium hydroxide to feed the pot mold Slot the mold with liquid; hoist the mold into the mold slot, start the mold, the mold liquid reacts violently, the temperature quickly reaches the boiling point, a large amount of alkali mist overflows, turn on the ventilation setting; after the mold is finished, lift the mold, open the 31# valve and 6# pump, clean the mold with a high-pressure atomizing water gun, dry and recycle the mold, the cleaning water flows into the 2# mold liquid collection tank through the diversion ditch, and recover the waste liquid; when the aluminum ion of the mold liquid reaches 60g / L or more, the The mold speed is getting slower and slower, ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com