Underwater pressure-bearing sealed cylinder and preparation method thereof

A technology of pressure-bearing sealing and sealing ring is applied in the field of underwater pressure-bearing sealing cylinder and its preparation, which can solve the problems of large navigation resistance and poor posture stability of the underwater pressure-bearing sealing cylinder, and achieve reliable water tightness, low cost, The effect of excellent sailing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

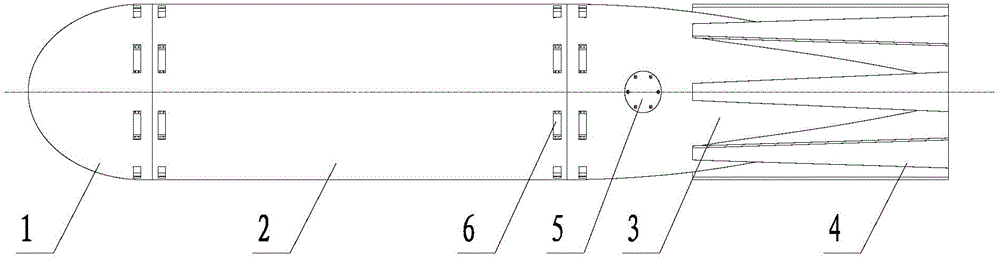

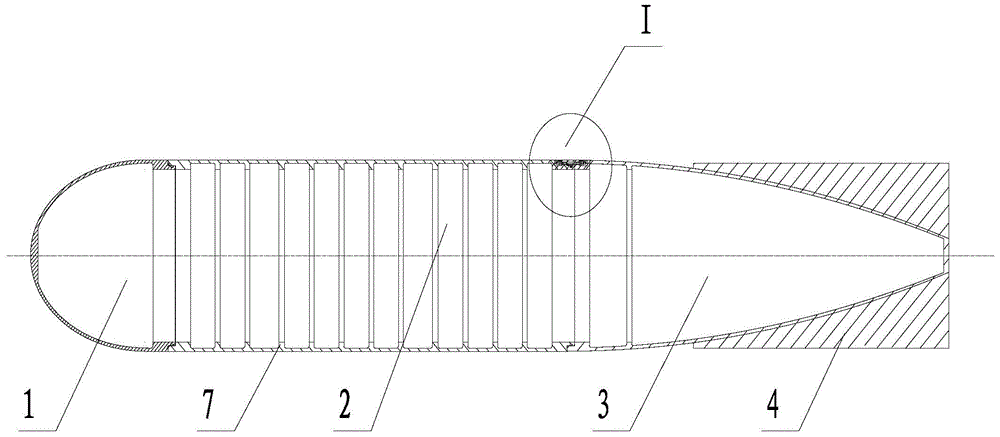

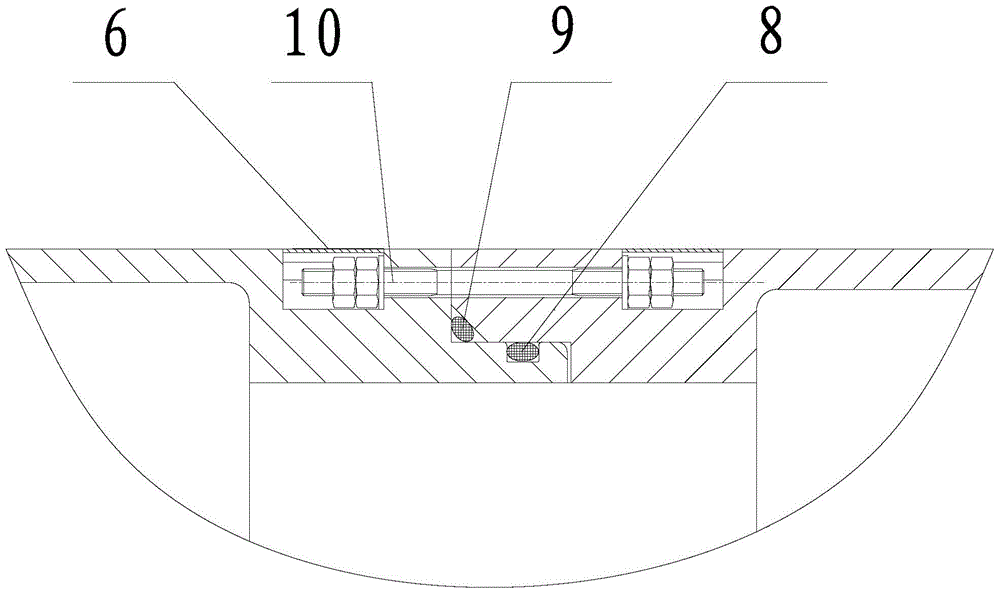

[0047] figure 1 It is a schematic diagram of the overall structure of the underwater pressure-bearing sealing cylinder according to the preferred embodiment of the present invention. Such as figure 1 As shown in , the sealing cylinder mainly includes a front part 1, a middle part 2 and a rear part 3. The front part 1 has a semi-ellipsoidal shape structure, which can effectively reduce the movement resistance of the underwater pressure-bearing sealing cylinder when navigating underwater. The rear part 3 is a convergent structure, and 8 stabilizing wings 4 are evenly distributed, which can effectively increase the stability of the attitude of the underwater pressure-bearing sealing cylinder when navigating underwater; Internal equipment maintenance and fault diagnosis. The middle part 2 is a cylindrical structure, which is integrally connected with the front part 1 and the rear part 3 by screwing. The length of the sealing cylinder can be adjusted by increasing or decreasing ...

Embodiment 2

[0076] The parameters of embodiment 2 are basically the same as those of embodiment 1, the differences are:

[0077] The element composition and the mass percentage of each element of the aluminum alloy raw material are as follows: Si 10.5%, Mg 0.35%, Mn 0.5%, Sr 0.06%, Cu0.09%, Zn 0.24%, Ti+Zr 0.14%, Sn 0.009%, Pb 0.04%, Fe 0.5%, B 0.07%, and the balance is Al.

[0078] After the casting is prepared, the casting is kept at a temperature of 530° C. for 360 minutes for solution treatment; then, the casting is kept at a temperature of 160° C. for 240 minutes for aging treatment.

Embodiment 3

[0080] The parameters of embodiment 3 are basically the same as those of embodiment 1, the differences are:

[0081] The elemental composition and the mass percentage of each element of the aluminum alloy raw material are as follows: Si 8%, Mg 0.17%, Mn 0.2%, Sr 0.02%, Ti+Zr 0.01%, B 0.005%, and the balance is Al.

[0082] After the casting is prepared, the casting is kept at a temperature of 530° C. for 360 minutes for solution treatment; then, it is kept at a temperature of 170° C. for 300 minutes for aging treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap length | aaaaa | aaaaa |

| Dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com