Bamboo wood sharpening machine feeding device

A feeding device and sharpening machine technology, applied in packaging, conveyors, biological packaging, etc., can solve the problems of complex equipment structure, poor feeding effect, high equipment cost, etc., to reduce noise pollution, prevent blockage, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

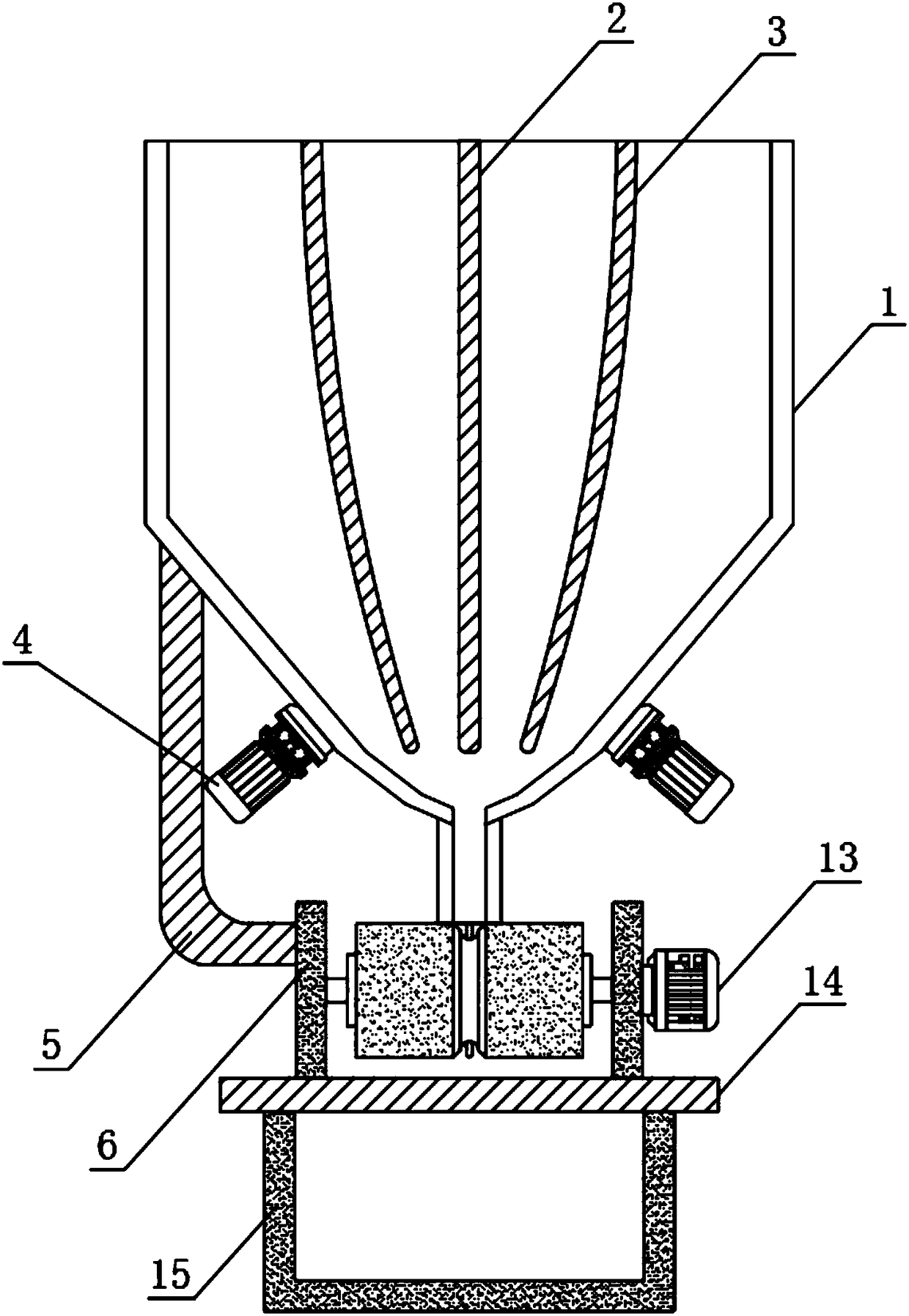

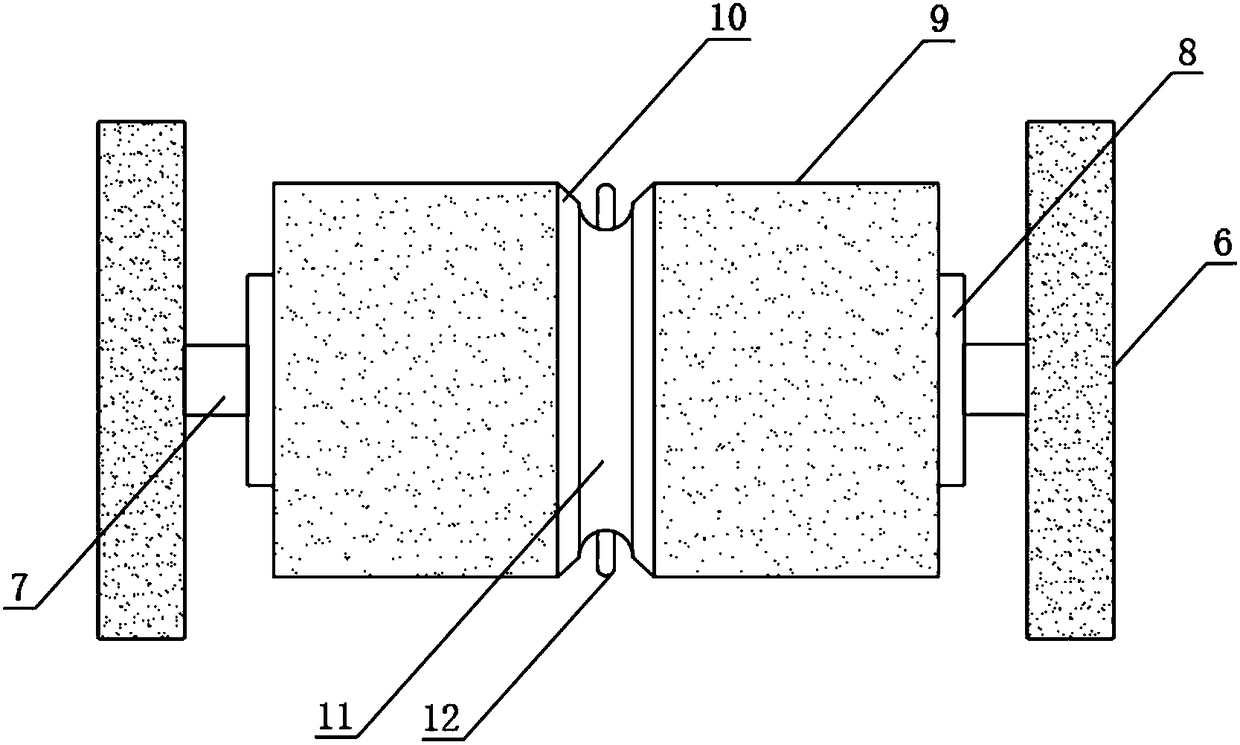

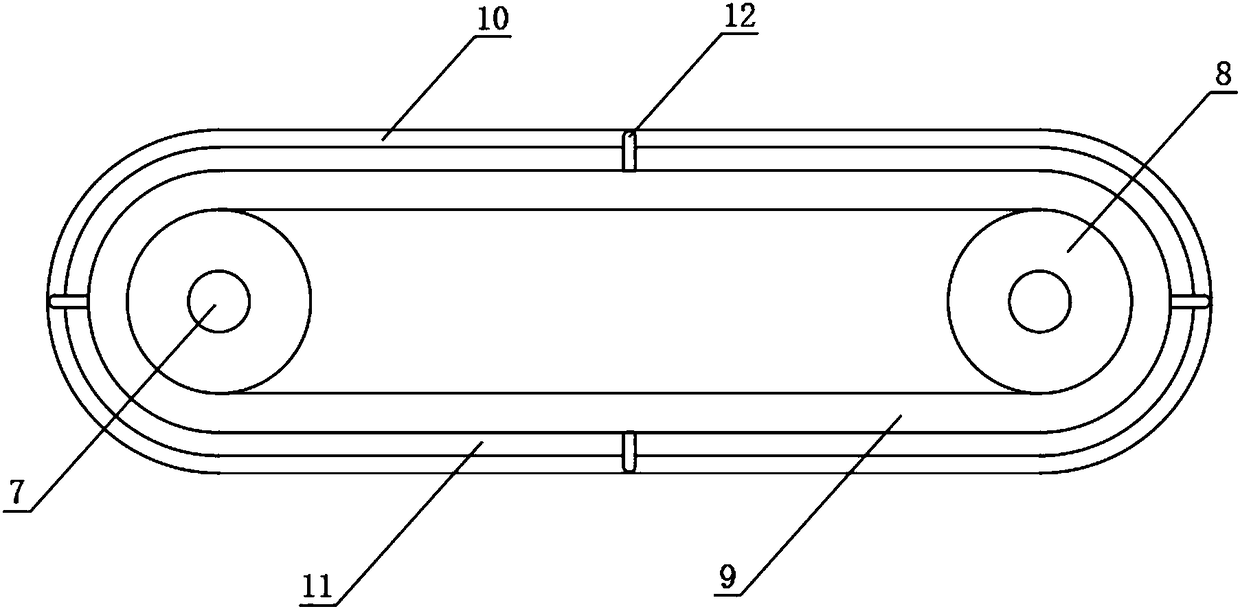

[0026] according to figure 1 A kind of bamboo sharpening machine feeding device shown, described hopper 1 interior is fixedly provided with first dividing plate 2, and described first dividing plate 2 cross-section is set to rectangle, and described first dividing plate 2 both sides A second partition 3 is provided, and the cross-section of the second partition 3 is set to be arc-shaped, so as to effectively divide the bamboo and wood, and prevent the bamboo and wood raw materials from skewing. The bottom of the first partition 2 and the second partition 3 The end edges are all provided with arc-shaped surfaces, so as to play a guiding role, and the bottom ends of both sides of the hopper 1 are fixed with a first motor 4, and the first motor 4 is set as a vibration motor, so that the first motor The vibration of 4 drives the hopper 1 to vibrate, thereby accelerating the descending speed of the bamboo and wood raw materials in the hopper 1, preventing the occurrence of the bloc...

Embodiment 2

[0029] The difference from Example 1 is that the inner side of the hopper 1, the outer side of the first partition 2 and the outer side of the second partition 3 are all equipped with sound-absorbing cotton, so as to effectively reduce the noise inside the hopper 1 when the first motor 4 drives the vibration of the hopper 1. The noise generated by the impact of the bamboo and wood raw materials on the inner wall of the hopper 1, the outside of the first partition 2 and the outside of the second partition 3 reduces the noise pollution during the use of the present invention.

[0030] Working principle of the present invention: when working, the bamboo and wood raw materials are put into the hopper 1, the setting of the first dividing plate 2 and the second dividing plate 3 can effectively divide the bamboo and wood to prevent the bamboo and wood raw materials from skewing, and then the bamboo and wood raw materials are made of 1 The discharge port at the bottom falls into the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com