Fodder thrower

A feeding device and feed technology, which is applied in the field of farming machinery, can solve problems such as loud noise, waste of feed, and the amount of difficult feed output, so as to reduce noise and ensure the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

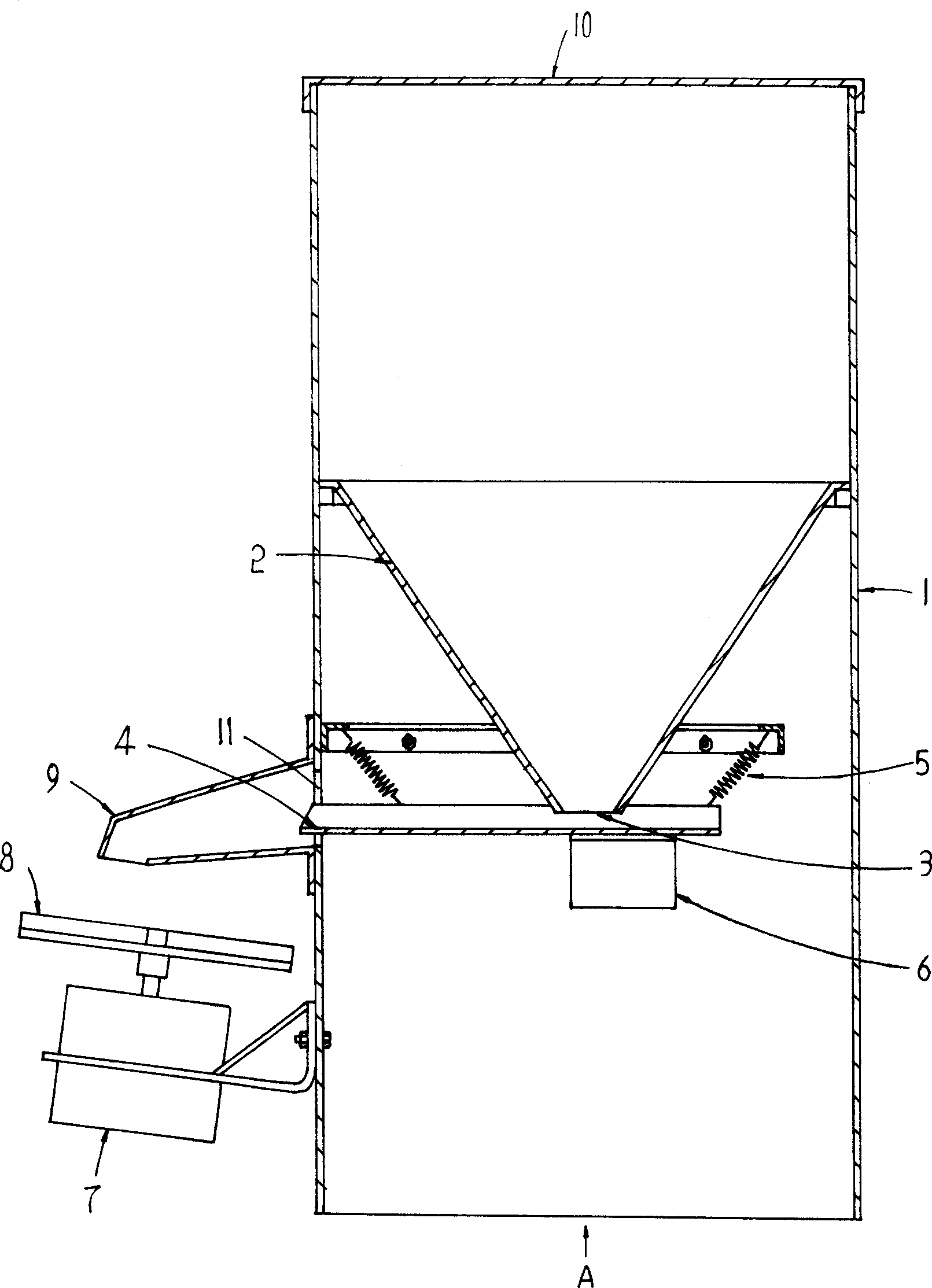

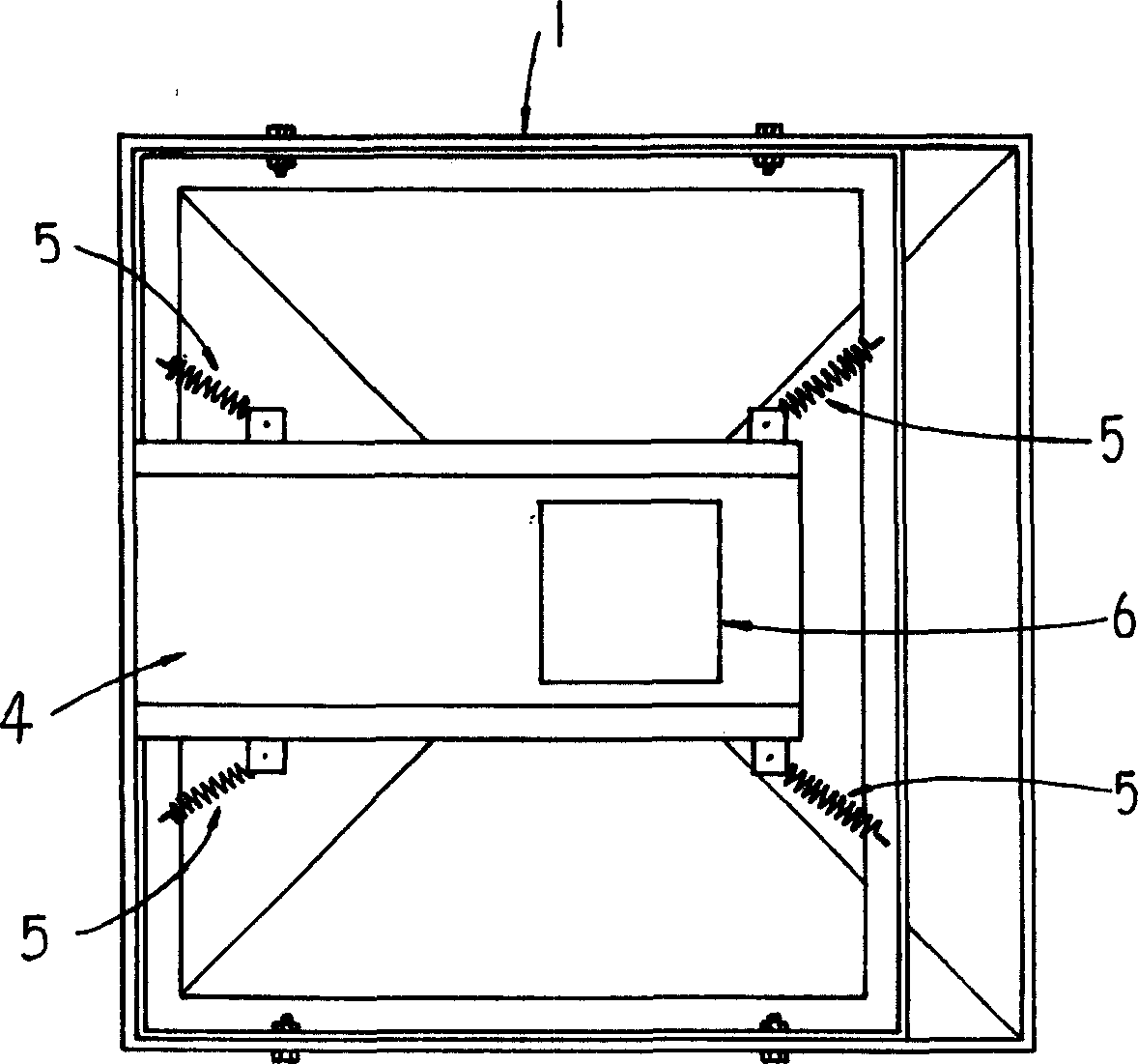

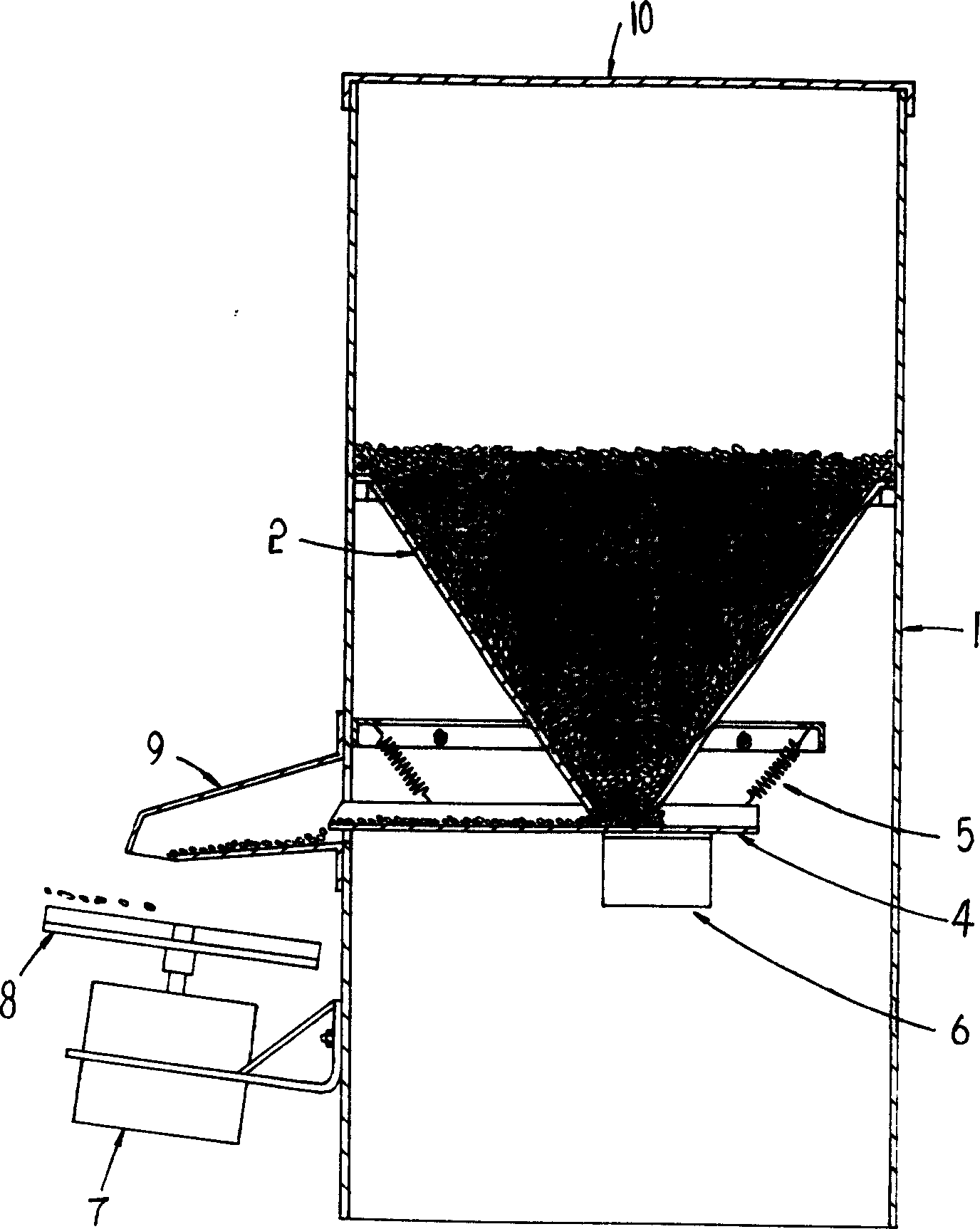

[0018] refer to figure 1 , figure 2 As shown, the feed feeding device of the present invention comprises a square box body 1, a feed bucket 2 fixed in the box body 1, a discharge port 3 is provided at the bottom of the feed bucket 2, and a discharge port 3 is provided on the lower side of the discharge port 3. Plate 4, the discharge plate 4 is supported by four elastic supports 5, the elastic support 5 adopts extension springs, and the two ends of the four extension springs are respectively fixedly connected with the inner wall of the box body 1 and the four corners of the discharge plate 4; A vibrator 6 is installed at the bottom of the plate 4, and the vibrator 6 is an electromagnetic vibrating coil. The vibration frequency can be adjusted by changing the voltage to adjust the output of the feed; There is a through hole 11, the front end of the discharge plate 4 protrudes out of the through hole 11, a material distribution motor 7 is fixed on the wall of the box body 1 bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com