Network cabinet production assembly line and production process

A technology for production lines and network cabinets, which is applied in spray booths, spray devices, chemical instruments and methods, etc., can solve the problems of low production efficiency and poor product consistency of network cabinets, and achieves excellent appearance quality, high production efficiency and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

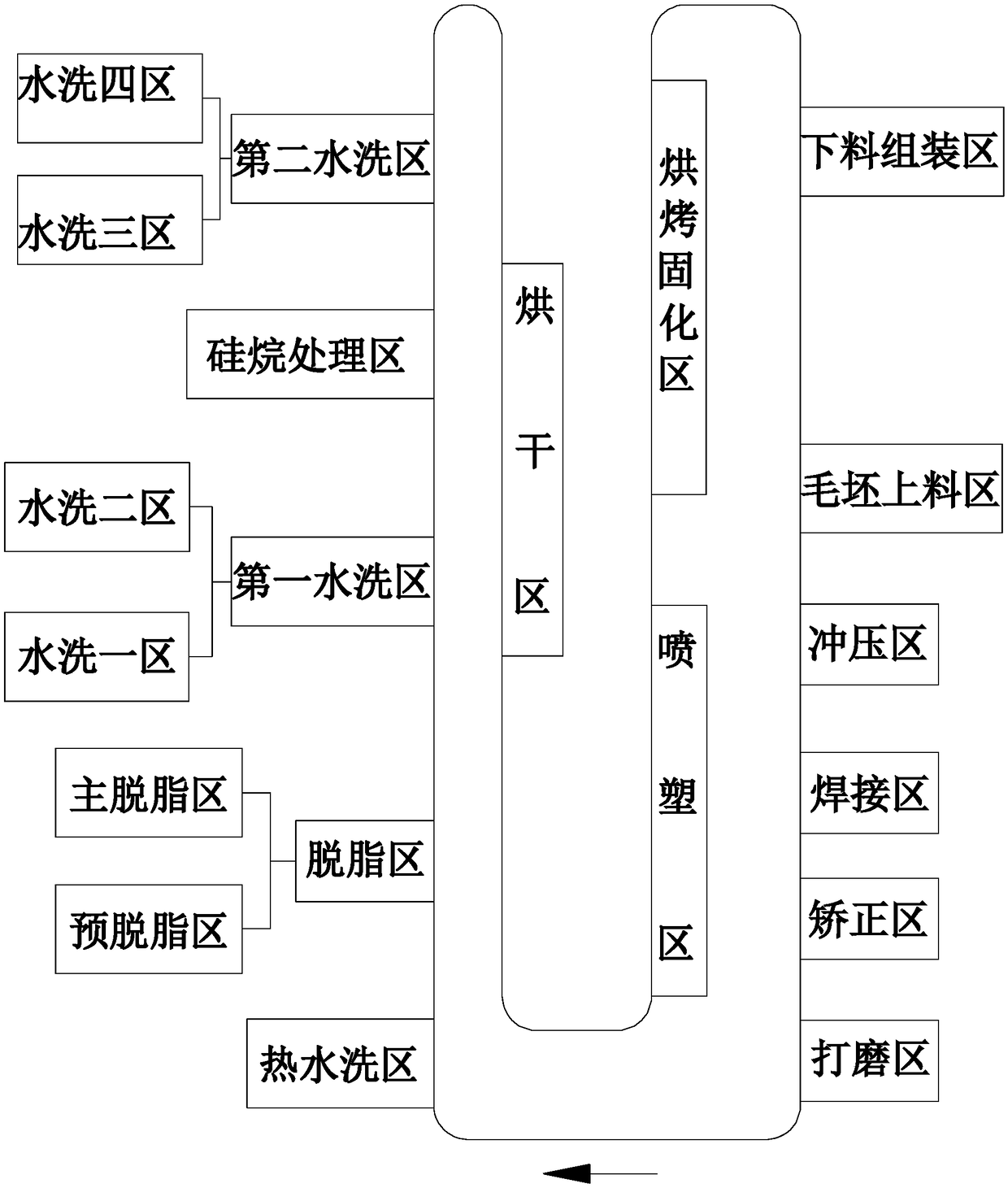

[0043] Such as figure 1 As shown, a network cabinet production line, including the blank feeding area, stamping area, welding area, correction area, grinding area, hot water washing area, degreasing area, first water washing area, silane treatment area, second water washing area, etc. Area, drying area, plastic spraying area, baking curing area, blanking and assembly area, also includes conveyor chain, driving device, the conveyor chain passes through the above-mentioned areas in turn, the driving device drives the conveyor chain to circulate, and the workpiece is suspended on the conveyor chain .

[0044] The present invention integrates each process in the production process of the network cabinet into a circulating assembly line, and sequentially transports the workpieces to each process through the conveying chain for corresponding processing. From the blank to the finished product, it can be realized on a production line. Compared with The distributed processing method i...

Embodiment 2

[0070] The present invention also discloses a production process based on the above-mentioned network cabinet production line, including the following steps:

[0071] A. Blank loading: hang the blank on the conveyor chain in the blank loading area, and the conveyor chain drives the blank to the stamping area;

[0072] B. Stamping: After the blank in step A is transported to the stamping area by the conveyor chain, it is removed, and the blank is stamped according to the production requirements. After the stamping is completed, it is a stamping part, and then the stamping part is hung on the conveyor chain. On the top, the conveyor chain drives the stamping parts to the welding area;

[0073] C. Welding: After the stamping parts in step B are transported to the welding area by the conveyor chain, they are removed, and the stamping parts are welded according to the production requirements. After the welding is completed, they are welded parts, and then the welded parts are hung ...

Embodiment 3

[0085] The present invention also discloses a production process based on the above-mentioned network cabinet production line, including the following steps:

[0086] A. Blank loading: hang the blank on the conveyor chain in the blank loading area, and the conveyor chain drives the blank to the stamping area;

[0087] B. Stamping: After the blank in step A is transported to the stamping area by the conveyor chain, it is removed, and the blank is stamped according to the production requirements. After the stamping is completed, it is a stamping part, and then the stamping part is hung on the conveyor chain. On the top, the conveyor chain drives the stamping parts to the welding area;

[0088] C. Welding: After the stamping parts in step B are transported to the welding area by the conveyor chain, they are removed, and the stamping parts are welded according to the production requirements. After the welding is completed, they are welded parts, and then the welded parts are hung ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com