Low-profile low-loss Rotman lens

A low-loss, low-profile technology, used in electrical components, radiating element structures, antennas, etc., can solve the problems of high lens profile and large loss, and achieve the effects of mature and reliable technology, good consistency, and stable energy transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

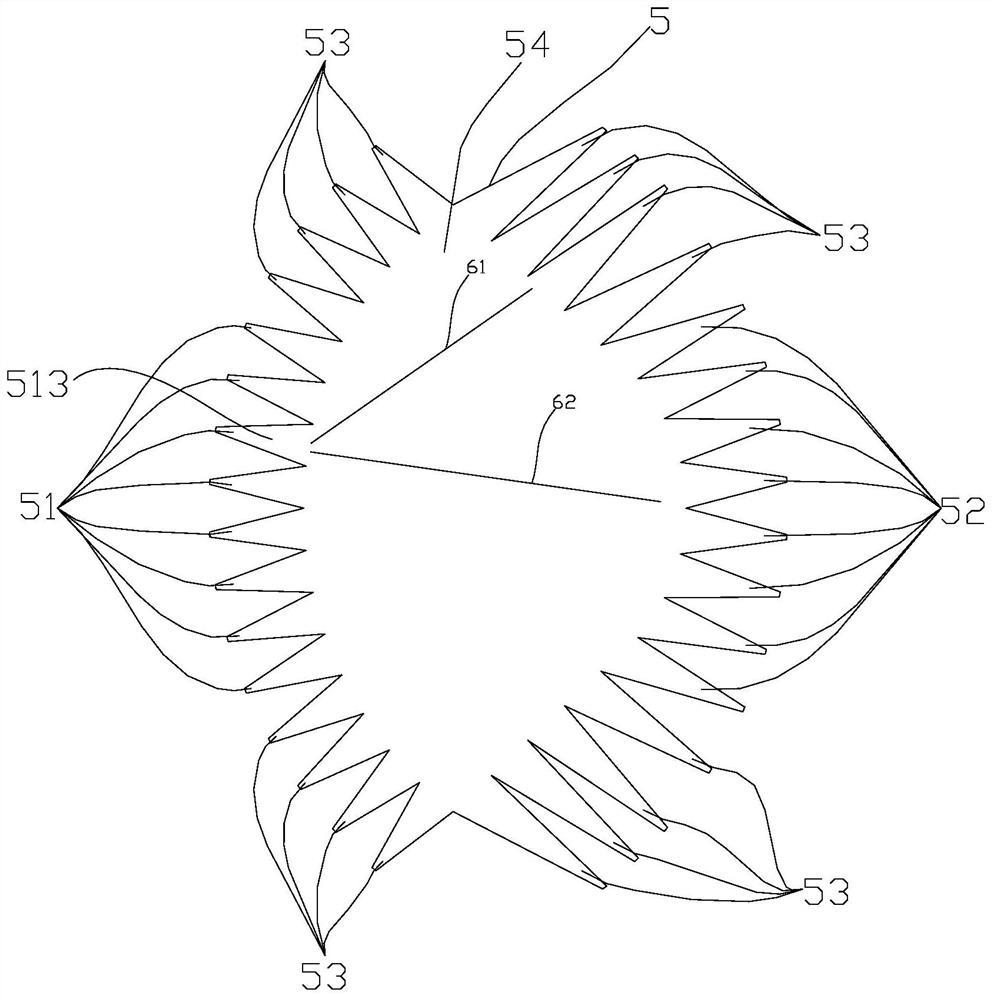

[0034] like figure 1Shown, the lens circuit 5 of traditional Rotman lens comprises input port 51, output port 52, vacant port 53 and lens body 54; Said vacant port 53 is positioned between input port 51 and output port 52; Traditional Rotman lens passes lens The body 54 completes the energy transmission between the input port 51 and the output port 52, and the energy transmission path satisfies the linear law of geometric optics, as shown in FIG. 3 . Taking the input port 513 as an example, the energy transmission path is similar to the first straight line 61 and the second straight line 62, causing part of the energy to be transmitted to the vacant port 53 area, resulting in energy loss.

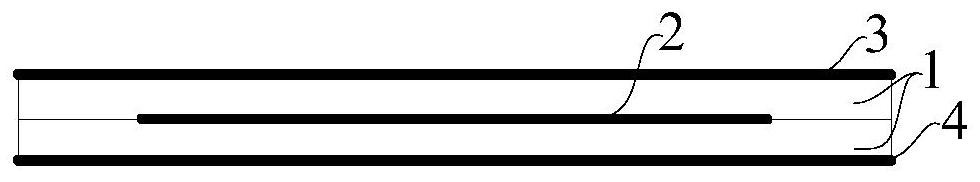

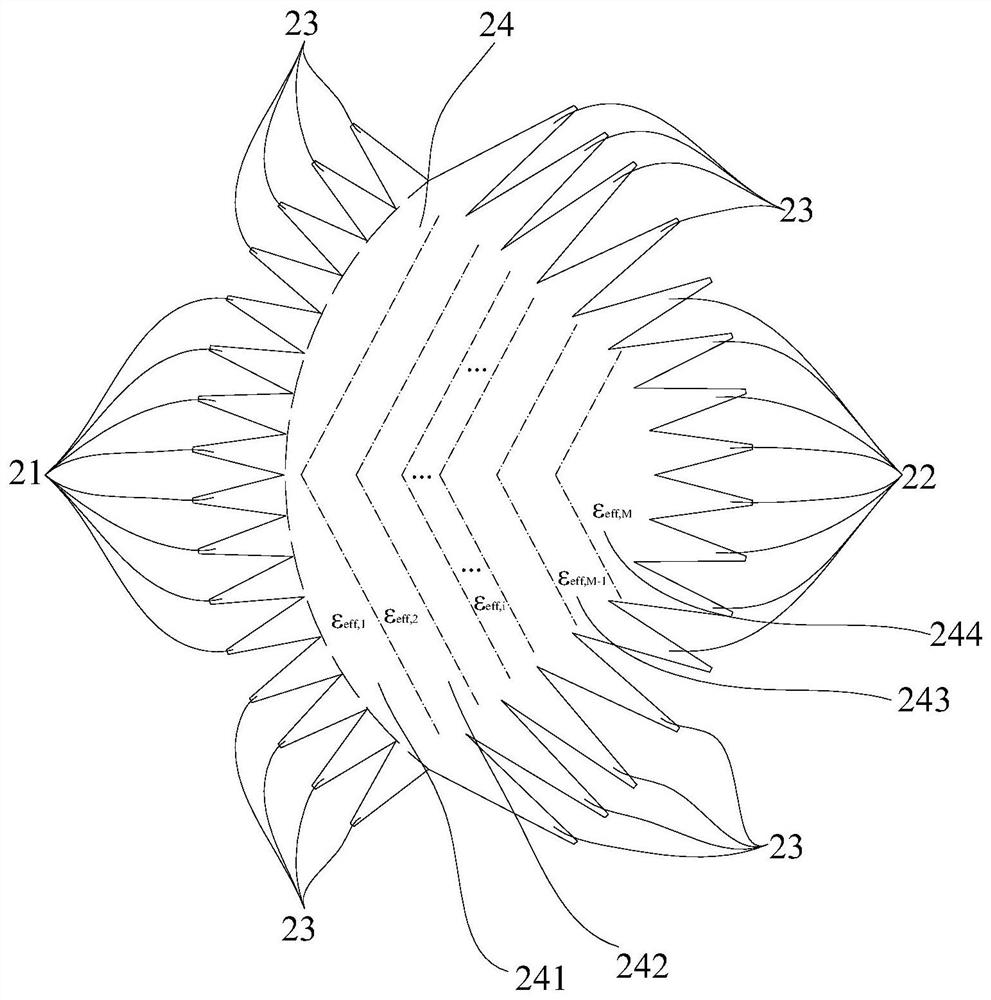

[0035] like figure 2 As shown, this embodiment proposes a low-profile and low-loss Rotman lens, including two layers of non-metallized dielectric substrate 1 and three layers of metallized copper-clad plane; the two-layer non-metallized dielectric substrate 1 is the upper layer of non-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com